Abstract

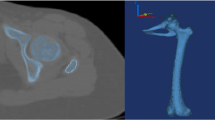

Long-term loosening is the major cause of failure of arthroplasty. One of the major causes is stress shielding, initiated by the large stiffness difference between prosthesis and bone tissue. Therefore, prosthesis with reduced stiffness properties to match those of the bone tissue may be able to minimize such a problem. Design with porous structure is believed to reduce the stiffness of the prosthesis, however at the cost of decreased strength. In this study, a patient-specific bone-implant finite element model was developed for contact mechanics study of hip joint, and algorithms were developed to adjust the elastic modulus of elements in certain regions of the femoral stem, until optimal properties were achieved according to the pre-defined criterions of the strength and stability of the system. The global safety factor of the optimized femoral stem was 11.3, and 26.4% of elements were designed as solid. The bone volume with density loss was reduced by 40% compared to the solid stem. The methodology developed in this study provides a universal method to design a patient-specific prosthesis with a gradient modulus distribution for the purposes of minimizing the stress shielding effect and extending the lifespan of the implant.

Similar content being viewed by others

References

Wilkinson J M, Hamer A J, Rogers A, Stockley I, Eastell R. Bone mineral density and biochemical markers of bone turnover in aseptic loosening after total hip arthroplasty. Journal of Orthopaedic Research, 2003, 21, 691–696.

Gibson I, Cheung L K, Chow S P, Cheung W L, Beh S L, Savalani M, Lee S H. The use of rapid prototyping to assist medical applications. Rapid Prototyping Journal, 2006, 12, 53–58.

Gong H, Wu W, Fang J, Dong X, Zhao M, Guo T. Effects of materials of cementless femoral stem on the functional adaptation of bone. Journal of Bionic Engineering, 2012, 9, 66–74.

Li Y, Yang C, Zhao H, Qu S, Li X, Li Y. New developments of Ti-based alloys for biomedical applications. Materials, 2014, 7, 1709–1800.

Huiskes R, Weinans H, Van Rietbergen B. The relationship between stress shielding and bone resorption around total hip stems and the effects of flexible materials. Clinical Orthopaedics and Related Research, 1992, 274, 124–134.

Arabnejad S, Johnston B, Tanzer M, Pasini D. Fully porous 3D printed titanium femoral stem to reduce stress-shielding following total hip arthroplasty. Journal of Orthopaedic Research Official Publication of the Orthopaedic Research Society, 2017, 35, 1774–1783.

Takemoto M, Fujibayashi S, Neo M, Suzuki J, Kokubo T, Nakamura T. Mechanical properties and osteoconductivity of porous bioactive titanium. Key Engineering Materials, 2005, 26, 6014–6023.

Hazlehurst K B, Wang C J, Stanford M. The potential application of a Cobalt Chrome Molybdenum femoral stem with functionally graded orthotropic structures manufactured using Laser Melting technologies. Medical Hypotheses, 2013, 81, 1096–1099.

Murr L, Gaytan S, Medina F, Lopez H, Martinez E, Machado B, Hernandez D, Martinez L, Lopez M, Wicker R. Next-generation biomedical implants using additive manufacturing of complex, cellular and functional mesh arrays. Philosophical Transactions of the Royal Society A: Mathematical, Physical and Engineering Sciences, 2010, 368, 1999–2032.

Arabnejad S, Burnett Johnston R, Pura J A, Singh B, Tanzer M, Pasini D. High-strength porous biomaterials for bone replacement: A strategy to assess the interplay between cell morphology, mechanical properties, bone ingrowth and manufacturing constraints. Acta Biomaterialia, 2016, 30, 345–356.

Gupta A, Talha M. Recent development in modeling and analysis of functionally graded materials and structures. Progress in Aerospace Sciences, 2015, 79, 1–14.

Gong H, Kong L, Zhang R, Fang J, Zhao M. A femurimplant model for the prediction of bone remodeling behavior induced by cementless stem. Journal of Bionic Engineering, 2013, 10, 350–358.

Bahraminasab M, Sahari B B, Edwards K L, Farahmand F, Hong T S, Arumugam M, Jahan A. Multi-objective design optimization of functionally graded material for the femoral component of a total knee replacement. Materials & Design, 2014, 53, 159–173.

Hedia H, Shabara M, El-Midany T, Fouda N. Improved design of cementless hip stems using two-dimensional functionally graded materials. Journal of Biomedical Materials Research Part B: Applied Biomaterials, 2006, 79, 42–49.

Hedia H. Comparison of one-dimensional and twodimensional functionally graded materials for the backing shell of the cemented acetabular cup. Journal of Biomedical Materials Research Part B: Applied Biomaterials, 2005, 74, 732–739.

Hedia H S, Fouda N. Design optimization of cementless hip prosthesis coating through functionally graded material. Computational Materials Science, 2014, 87, 83–87.

Oshkour A A, Osman N A A, Bayat M, Afshar R, Berto F. Three-dimensional finite element analyses of functionally graded femoral prostheses with different geometrical configurations. Materials & Design, 2014, 56, 998–1008.

Khanoki S A, Pasini D. Multiscale design and multiobjective optimization of orthopedic hip implants with functionally graded cellular material. Journal of Biomechanical Engineering, 2012, 134, 031004.

Hazlehurst K B, Wang C J, Stanford M. A numerical investigation into the influence of the properties of cobalt chrome cellular structures on the load transfer to the periprosthetic femur following total hip arthroplasty. Medical Engineering & Physics, 2014, 36, 458–466.

Yan W, Berthe J, Wen C. Numerical investigation of the effect of porous titanium femoral prosthesis on bone remodeling. Materials & Design, 2011, 32, 1776–1782.

Rho J, Hobatho M, Ashman R. Relations of mechanical properties to density and CT numbers in human bone. Medical Engineering & Physics, 1995, 17, 347–355.

Pettersen S H, Wik T S, Skallerud B. Subject specific finite element analysis of implant stability for a cementless femoral stem. Clinical Biomechanics, 2009, 24, 480–487.

Heller M O, Bergmann G, Kassi J P, Claes L, Haas N P, Duda G N. Determination of muscle loading at the hip joint for use in pre-clinical testing. Journal of Biomechanics, 2005, 38, 1155–1163.

Murr L E, Gaytan S M, Martinez E, Medina F, Wicker R B. Next generation orthopaedic implants by additive manufacturing using electron beam melting. International Journal of Biomaterials, 2012, 2012, 245727.

Sridhar I, Adie P P, Ghista D N. Optimal design of customised hip prosthesis using fiber reinforced polymer composites. Materials & Design, 2010, 31, 2767–2775.

Amin Yavari S, Wauthle R, Van Der Stok J, Riemslag A C, Janssen M, Mulier M, Kruth J P, Schrooten J, Weinans H, Zadpoor A A. Fatigue behavior of porous biomaterials manufactured using selective laser melting. Materials Science and Engineering: C, 2013, 33, 4849–4858.

Kuiper J, Huiskes R. The predictive value of stress shielding for quantification of adaptive bone resorption around hip replacements. Journal of Biomechanical Engineering, 1997, 119, 228–231.

Turner A W L, Gillies R M, Sekel R, Morris P, Bruce W, Walsh W R. Computational bone remodelling simulations and comparisons with DEXA results. Journal of Orthopaedic Research Official Publication of the Orthopaedic Research Society, 2005, 23, 705–712.

Ike H, Inaba Y, Kobayashi N, Hirata Y, Yukizawa Y, Aoki C, Choe H, Saito T. Comparison between mechanical stress and bone mineral density in the femur after total hip arthroplasty by using subject-specific finite element analyses. Computer Methods in Biomechanics & Biomedical Engineering, 2014, 18, 1–10.

Sola A, Bellucci D, Cannillo V. Functionally graded materials for orthopedic applications–An update on design and manufacturing. Biotechnology Advances, 2016, 34, 504–531.

Mahmoud D, Elbestawi M. Lattice structures and functionally graded materials applications in additive manufacturing of orthopedic implants: A review. Journal of Manufacturing and Materials Processing, 2017, 1, 13.

Bieger R, Ignatius A, Reichel H, Dürselen L. Biomechanics of a short stem: In vitro primary stability and stress shielding of a conservative cementless hip stem. Journal of Orthopaedic Research Official Publication of the Orthopaedic Research Society, 2013, 31, 1180–1186.

Chen Z, Zhang Z, Wang L, Li D, Zhang Y, Jin Z. Evaluation of a subject-specific musculoskeletal modelling framework for load prediction in total knee arthroplasty. Medical Engineering & Physics, 2016, 38, 708–716.

Wang L, Kang J, Sun C, Li D, Cao Y, Jin Z. Mapping porous microstructures to yield desired mechanical properties for application in 3D printed bone scaffolds and orthopaedic implants. Materials & Design, 2017, 133, 62–68.

Acknowledgment

The work was supported by the funding from the program of the National Nature Science Foundation of China (Grant Nos. 51205303 and 51323007), the program of Scientific and Technological Innovation in Shaanxi Province (Grant No. 2014KTZB01-02), the Fundamental Research Funds for the Central Universities, and Research Fund for the Doctoral Program (RFDP) of Higher Education of China.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sun, C., Wang, L., Kang, J. et al. Biomechanical Optimization of Elastic Modulus Distribution in Porous Femoral Stem for Artificial Hip Joints. J Bionic Eng 15, 693–702 (2018). https://doi.org/10.1007/s42235-018-0057-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42235-018-0057-1