Abstract

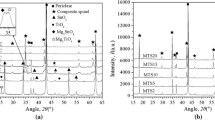

The effect of micromonoclinic ZrO2 addition on properties of CaO-based refractories was investigated in our work. Zero, 5 wt%, 10 wt%, and 15 wt% micromonoclinic ZrO2 powders were added into CaO-MgO (CaO-based) refractories. The obtained results indicated that with the introduction of micromonoclinic ZrO2, the density increased slightly after heated at 1600 °C for 3 h. The results indicated that the density and mechanical properties of the samples were improved after introducing micromonoclinic ZrO2. The hydration resistance of the samples was improved with appropriate proportion of ZrO2. However, excessive ZrO2 damaged the hydration resistance of the samples. The influence of monoclinic ZrO2 on the samples was mainly caused by CaZrO3, the reaction product of CaO and ZrO2. The details of the CaZrO3 effects on the samples were discussed in this paper. Besides, based on the experiment results, CaO-based crucible was prepared and used in desulfurization. The desulfurization effects were compared with desulfurizer: Al. Desulfurizer reduced the content of [O] and [S] in the alloy obviously.

Similar content being viewed by others

References

Thellaputta, G.R., Chandra, P.S., Raoc, C.S.P.: Machinability of nickel based superalloys: a review. Mater. Today Proc. 4(2), 3712–3721 (2017)

Praveen, K.V.U., Sastry, G.V.S., Singh, V.: Work-hardening behavior of the Ni-Fe based superalloy IN718. Metall. Mater. Trans. A. 39(1), 65–78 (2008)

Maktouf, W., Ammar, K., Naceur, I.B., et al.: Multiaxial high-cycle fatigue criteria and life prediction: application to gas turbine blade. Int. J. Fatigue. 92, 25–35 (2016)

Kwong, J.: Minor cutting edge–workpiece interactions in drilling of an advanced nickel-based superalloy. Int. J. Mach. Tools Manuf. 49(7), 645–658 (2009)

Grosu, Y., Bondarchuk, O., Faik, A.: The effect of humidity, impurities and initial state on the corrosion of carbon and stainless steels in molten HitecXL salt for CSP application. Sol. Energy Mater. Sol. Cells. 174, 34–41 (2018)

Gu, K., Dogan, N., Coley, K.S.: The effect of sulfur concentration in the metal on the mass transfer of phosphorus in bloated metal droplets. Steel Research International (2018)

Jacobi. The Process Metallurgy and Material Engineering of Steel with High Purity and Cleanness. 37th International Refractories Colloquium. 1994, Aachen. Germany.

Chen B, Ma Y, Gao M, et al. Changes of oxygen content in molten TiAl alloys as a function of superheat during vacuum induction melting[J]. J. Mater. Sci. Technol., 2010, 26(10):0-903.

Lin, W., Nomura, O., Nakamura, R., Uchida, S., Morio, E.: Decarbonization behavior of graphite-containing refractories by molten steel. Taikabutsu Orerseas. 19(4), 15–24 (1999)

Soltanieh, M., Payandeh, Y.: The relationship between oxygen chemical potential and steel cleanliness. J. Iron Steel Res. Int. 12(5), 28 (2005)

Kijac, J., Kovac, P., Steranka, E., Masek, V., Marek, P.: Metalurgija. 43, 59–62 (2004)

Jianping, N., Yang, K., Xiaofeng, S., Tao, J., Hengrong, G., Hu, Z.: Denitrogenation and desulphurization in vim for ni-based superalloy refining. Rare Metal Mater. Eng. 32(1), 63–66 (2003)

Niu, J.-P., Sun, X.-F., Jin, T., Yang, K.-N., Guan, H.-R., Hu, Z.-Q.: Study on deoxidations during VIM refining Ni-base superalloy by using CaO crucible. J. Mater. Eng. 12(10), 36–38 (2002)

Junfeng, C., Liugang, C., Yaowu, W., Nan, L., Shaowei, Z.: Corrosion and penetration behaviors of slag/steel on the corroded interfaces of Al2O3-C refractories: role of Ti3AlC2. Corros. Sci. 143, 166–176 (2018) (SCI)

Yeprem, H.A., Türedi, E., Karagöz, S.: A quantitative-metallographic study of the sintering behaviour of dolomite. Mater. Charact. 52(4), 331–340 (2004)

Mingxue, J., Zhaoyou, C.: Penetration of Al2O3 and CaF2 containing secondary refining slags into magnesia-dolomite refractories. Ironmak. Steelmak. 7(28), 21–25 (1993)

H Nnkagawa. Development of MgO-CaO-Al2O3 castable for steel ladle slag line. Proc. UNITECR :203 (1997).

Xinming, R., Ma, B., et al.: Slag corrosion characteristics of MgO-based refractories under vacuum electromagnetic field. J. Aust. Ceram. Soc. 1–8. https://doi.org/10.1007/s41779-019-00323-9

Maya, K., Matsuo, T.: Removal of chronium from molten steel by oxidation refining. Tetsu-to-Hagane. 77(3), 369–376 (2009)

Kobayashi, Y., Kodama, S.: Effect of CaO on Dephosphorising Ability of Deoxidation Slag for Effective Utilisation of Phosphorus in Steel. Trans. Iron Steel. Inst. Jpn. 52(6), 960–966 (2012)

Zhang, Q., Yaowu, W., Zhang, T., et al.: Preparation of CaO granules using the granulation method. Adv. Appl. Ceram. 6, 1–6 (2018)

Yaowu, W., Tao, Z., Qi, Z., Bingqiang, H., Nan, L.: Improvement in hydration resistance of CaO granules by addition of Zr(OH)4 and Al(OH)3. J. Am. Ceram. Soc. 00, 1–11 (2018). https://doi.org/10.1111/jace.15952

Junfeng, C., Nan, L., Yaowu, W., et al.: Influence of carbon sources on nitriding process, microstructures and mechanical properties of Si3N4, bonded SiC refractories. J. Eur. Ceram. Soc. 37(4), 1821–1829 (2017)

Ghasemi-Kahrizsangi, S., Barati Sedeh, M., Gheisari Dehsheikh, H., et al.: Densification and properties of ZrO2 nanoparticles added magnesia–doloma refractories. Ceram. Int. S0272884216310744 (2016)

Dehsheikh, H.G., Karamian, E., Owsalou, R.G., et al.: Improvement in performance of MgO–CaO refractory composites by addition of Iron (III) oxide nanoparticles. Ceram. Int. S0272884218314329 (2018)

Guanyao, C., Baotong, L., Zhang, H., et al.: On the modification of hydration resistance of CaO with ZrO2 additive. Int. J. Appl. Ceram. Technol. 13(6), 1173–1181 (2016)

Meng Fanlong, Cheng Zhiwei, Chen Guangyao, et al. Hydration resistance of Y2O3 doped CaO and its application to melting titanium alloys. Charact. Miner. Metals Mater. (2016)

Yong, D., Jin, Z.: Z, Huang Peiyun. Thermodynamic calculation of the zirconia–calcia system. J. Am. Ceram. Soc. 75(11), 3040–3048 (2010)

Schafföner, S., Aneziris, C.G., Berek, H., et al.: Fused calcium zirconate for refractory applications. J. Eur. Ceram. Soc. 33(15-16), 3411–3418 (2013)

Kim, S.K., Kim, T.K., Kim, M.G., et al.: Investment casting of titanium alloy with CaO crucible and CaZrO3 mold. Lightweight Alloys for Aerospace Application, pp. 251–260. Wiley, Hoboken (2013)

Ewais, E.M.M., Bayoumi, I.M.I.: Fabrication of MgO-CaZrO3, refractory composites from Egyptian dolomite as a clinker to rotary cement kiln lining. Ceram. Int. 44, 9236–9246 (2018)

Rodaev Vyacheslav, V., Zhigachev Andrey, O., Golovin, Y.I.: Microstructure and phase composition of CaO doped zirconia nanofibers. Ceram. Int. 43(1), 1200–1204 (2017)

Chen, M., Lu, C., Jingkun, Y.: Improvement in performance of MgO-CaO refractories by addition of nano-sized ZrO2. J. Eur. Ceram. Soc. 27, 4633–4638 (2007)

Shahraki, A., Ghasemi-kahrizsangi, S., Nemati, A.: Performance improvement of MgO-CaO refractories by the addition of nano-sized Al2O3 [J]. Mater. Chem. Phys. 198, 354–359 (2017)

Li, Z., Zhang, S., Lee, W.E.: Improving the hydration resistance of lime-based refractory materials. Metall. Rev. 53(1), 1–20 (2013)

Hu, B., Xu, Y., Hongda, Z.: Special refractories operative technology directory. Metallurgical Industrial Press, Beijing (2004)

Rodríguez, J.L., Rodríguez, M.A., et al.: Reaction sintering of zircon-dolomite mixtures. J. Eur. Ceram. Soc. 21, 343–354 (2001)

Richardson, D.W.: Modern ceramic engineering. Marcel Dekker, Properties Processing and Use in Design (1992)

Junfeng, C., Nan, L., Hubálková, J., Aneziris, C.G.: Elucidating the role of Ti3AlC2 in low carbon MgO-C refractories: antioxidant or alternative carbon source? J. Eur. Ceram. Soc. 38, 3387–3394 (2018)

Jianping, N., Yang, K., Xiaofeng, S., Tao, J., Hengrong, G., Hu, Z.: Denitrogenation and desulphurization in VIM for Ni-base superalloy refining. Rare Metal Mater. Eng. 32(1), 63–66 (2003)

Guo, W., Yu, S., He, Y., Shen, F.: Study on the desulfurization of hot metal with composite reagent of calcium oxide and aluminum [J]. J. North. Univ. (Nature Science). 33(12), 1737–1740 (2012)

Liang, L.-k., Yin-chang, C., Yang, H., et al.: Metallurgy thermodynamics and kinetics [M]. Shenyang: North. Univ. Technol. Press. 201, 208–211 (1990)

Gao, F.: Smelting metallic magnesium experimental study of vacuum metal thermal reduction technology with magnesite as raw material [D]. Northeastern University, Shen Yang (2010)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, T., Wei, Y., Chen, J. et al. Preparation of CaO-MgO-ZrO2 refractory and its desulfurization effect on Ni-based alloy in vacuum induction melting (VIM). J Aust Ceram Soc 56, 885–894 (2020). https://doi.org/10.1007/s41779-019-00421-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41779-019-00421-8