Abstract

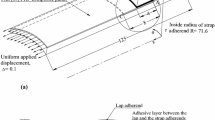

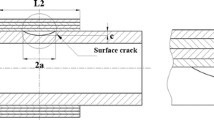

Delamination damage is one of the major type of fractures encountered by laminated FRP structures, greatly effecting their structural stability. Development of finite element method (FEM) based modelling and simulation technique in order to analyze delamination growth in laminated FRP composite made single lap pipe joints, is the prime concern of the present research. Layered solid 185 elements of ANSYS 18.0 has been used for modelling the FRP composite tubes. Ansys Parametric Design Language (APDL) codes have been developed to simulate delaminations and study their effect on interlaminar stresses. Delamination damages have been considered in the ply-interfaces of the composite tubes in the close vicinity of the adhesive layer and their effect on the adhesive mid-layer stresses has been studied. Comparison of delamination damages in the outer and inner tubes on adhesive stresses revealed that damages in the inner tube are more critical as compared to the delaminated outer adherend.

Similar content being viewed by others

References

Aydin MD (2008) 3-D nonlinear stress analysis on adhesively bonded single lap composite joints with different ply stacking sequences. J Adhes 84:15–36

Baishya N, Das RR, Panigrahi SK (2017) Failure analysis of adhesively bonded tubular joints of laminated FRP composites subjected to combined internal pressure and torsional loading. J Adhes Sci Tech. https://doi.org/10.1080/01694243.2017.1307498

da Silva Lucas FM et al (2009) Analytical models of adhesively bonded joints-Part I: literature survey. Int J Adhes Adhes 29:319–330

Das RR, Pradhan B (2010) Adhesion failure analyses of bonded tubular single lap joints in laminated fibre reinforced plastic composites. Int J Adhes Adhes 30:425–438

Das RR, Pradhan B (2011) Finite element based design and adhesion failure analysis of bonded tubular socket joints made with laminated FRP composites. J Adhes Sci Tech 25:41–67

Das RR, Pradhan B (2014) Delamination damage analysis of laminated bonded tubular single lap joint made of fiber-reinforced polymer composite. Int J Damage Mech 23:772–790

Esmaeel RA, Taheri F (2009) Stress analysis of tubular adhesive joints with delaminated adherend. J Adhes Sci Tech 23:1827–1844

Esmaeel RA, Taheri F (2011) Influence of adherend’s delamination on the response of single lap and socket tubular adhesively bonded joints subjected to torsion. Compos Struct 93:1765–1774

Hipol PJ (1984) Analysis and optimization of a tubular lap joint subjected to torsion. J Comp Mater 18:298–311

Hosseinzadeh R, Taheri F (2009) Non-linear investigation of overlap length effect on torsional capacity of tubular adhesively bonded joints. Compos Struct 91:186–195

Oh JH (2007) Nonlinear analysis of adhesively bonded tubular single-lap joints for composites in torsion. Compos Sci Tech 67:1320–1329

Panigrahi SK, Pradhan B (2007) Delamination damage analyses of adhesively bonded lap shear joints in laminated FRP composites. Int J Fract 148:373–385

Qin M, Dzenis YA (2003) Analysis of single lap adhesive composite joints with delaminated adherends. Composites 34B:167–173

Tong L, Zhu XC, Steven GP (1998) Damage tolerance of adhesively bonded composite single lap joints. Key Engng Mater 149:537–542

Xu W, Li G (2010) Finite difference three-dimensional solution of stresses in adhesively bonded composite tubular joint subjected to torsion. Int J Adhes Adhes 30:191–199

Yang C (2000) Design and analysis of composite pipe joints under tensile loading. J Compos Mater 34:332–349

Yang C, Huang H, Guan Z (2002) Stress model of composite pipe joints under bending. J Compos Mater 36:1331–1348

Zou GP, Taheri F (2006) Stress analysis of adhesively bonded sandwich pipe joints subjected to torsional loading. Int J Solids Struct 43:5953–5968

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kumar, U., Kumar, P., Noor, M.T. et al. FEM based delamination damage analysis of bonded FRP composite pipe joints. ISSS J Micro Smart Syst 7, 45–51 (2018). https://doi.org/10.1007/s41683-018-0022-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41683-018-0022-6