Abstract

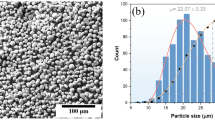

A high-strength steel X22CrMoV 12-1 was fabricated using the laser powder bed fusion (LPBF) process with optimized parameters to result in a nearly dense (99.95%) coupons in the as-printed condition. Trials to optimize the heat treatment condition with respect to the microstructure were carried out. The first set of experiments involved Oil Quenching after 2 h and 8 h of solutionizing at 1020 °C, 1070 °C, 1085 °C and 1100 °C, followed by tempering at 660 °C, 690 °C, 720 °C, for 2 h. The optimized heat treatment was evolved as, solutionizing at 1070 °C, 2 h in vacuum followed by argon gas quenching and tempering at 660 °C, for 2 h, resulting in a tempered martensite microstructure. The as-printed micro-hardness was ~ 400 HV, while the oil quenched micro-hardness increased to 525 HV and the tempered hardness was at 270–280 HV. Tensile tests carried out at room temperature and at high temperature revealed that the tensile behavior resembles that of the wrought alloy. A set of prototype demonstration components were manufactured for a steam turbine and the tensile behaviour in samples made in these builds were also obtained demonstrating the potential additive manufacturing for such parts.

Similar content being viewed by others

References

Ansell TY, Ricks JP, Park C, Tipper CS, Luhrs CC (2020) Mechanical properties of 3D-printed maraging steel induced by environmental exposure. Metals 10:218. https://doi.org/10.3390/met10020218

Bawane KK, Srinivasan D, Banerjee D (2018) Microstructural evolution and mechanical properties of direct metal laser-sintered (DMLS) CoCrMo after heat treatment. Metall Mater Trans A 49:3793–3811. https://doi.org/10.1007/s11661-018-4771-4

Damon J, Koch R, Kaiser D, Graf G, Dietrich S, Schulze V (2019) Process development and impact of intrinsic heat treatment on the mechanical performance of selective laser melted AISI 414. Addit Manuf 28:275–284. https://doi.org/10.1016/j.addma.2019.05.012

Do T, Bauder TJ, Suen H, Rego K, Yeom J, Kwon P (2018) Additively Manufactured Full-Density Stainless Steel 316L With Binder Jet Printing. In: ASME 2018 13th international manufacturing science and engineering conference. https://doi.org/10.1115/MSEC2018-6681

Dutta B, Froes FH (2016) Additive manufacturing technology. Additive manufacturing of titanium alloys, Illustrated. Butterworth Heinemann, Oxford, pp 25–40

Graybill B, Li M, Malawey D, Ma C, Orozco JMA, Franco EM (2018) Additive manufacturing of nickel-based superalloys. In: ASME 2018 13th international manufacturing science and engineering conference. https://doi.org/10.1115/MSEC2018-6666

Gu D, Wang H, Dai D (2015) Laser additive manufacturing of novel aluminum based nanocomposite parts: tailored forming of multiple materials. J Manuf Sci Eng 138:021004–021015. https://doi.org/10.1115/1.4030376

Ho CMB, Ng SH, Yoon YJ (2015) A review on 3D printed bioimplants. Int J Precis Eng Manuf 16:1035–1046. https://doi.org/10.1007/s12541-015-0134-x

Jin W, Zhang C, Jin S, Tian Y, Wellmann D, Liu W (2020) Wire arc additive manufacturing of stainless steels: a review. Appl Sci 10:1563. https://doi.org/10.3390/app10051563

Leal R, Barreiros FM, Alves L, Romeiro F, Vasco JC, Santos M (2017) Additive manufacturing tooling for the automotive industry. Int J Adv Manuf Technol 92:1671–1676. https://doi.org/10.1007/s00170-017-0239-8

Mangour BA (2015) Powder metallurgy of stainless steel: state-of-the art, challenges, and development. In: Steel S (ed) Stainless steel: microstructure, mechanical properties and methods of application, 1st edn. Nova Science Publishers Inc, Saudi Arabia, p 41

Novotny V, Spale J, Stunova BB, Kolovratnik M, Vitvarova M, Zikmund P (2019) 3D Printing in Turbomachinery: Overview of Technologies, Applications and Possibilities for Industry 4.0. In: ASME Turbo Expo 2019: Turbomachinery Technical Conference and Exposition. https://doi.org/10.1115/GT2019-91849

Yusuf SM, Cutler S, Gao N (2019) Review: the impact of metal additive manufacturing on the aerospace industry. Metals 9(12):1286. https://doi.org/10.3390/met9121286

Zai L, Zhang C, Wang Y, Guo W, Wellmann D, Tong X, Tian Y (2020) Laser powder bed fusion of precipitation-hardened martensitic stainless steels: a review. Metals 10:255. https://doi.org/10.3390/met10020255

Zumofen L, Kirchheim A, Dennig HJ (2020) Laser powder bed fusion of 30CrNiMo8 steel for quenching and tempering: examination of the process ability and mechanical properties. Prog Addit Manuf 5:75–81. https://doi.org/10.1007/s40964-020-00121-x

Acknowledgements

This research was carried out with funding from the IMPRINT program (5868) entitled “Land based turbine components with additive manufacturing in a consortium approach”. The program has been carried in a collaborative approach between Indian Institute of Science, Intech Additive Solutions., and Triveni Turbines. The support and. contributions of Mr Raghunandan M and Mr Jagadish CA, formerly in Intech Additive Solutions, is gratefully acknowledged. The use of facilities at the Department of Materials Engineering at IISc and AFMM, IISc is also acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mathias, S., Srinivasan, D., Setty, R. et al. Additive Processing of a X22CrMoV12-1 Steel: Structure, Properties and Product. Trans Indian Natl. Acad. Eng. 6, 283–295 (2021). https://doi.org/10.1007/s41403-020-00191-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41403-020-00191-x