Abstract

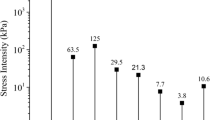

Lack of attention to the effect of laboratory conditions on the results of asphalt mixture tests, especially these of the warm mix asphalt (WMA), makes the analysis of results misleading. Thus herein, after examining the research on WMA and factors affecting test results in laboratory conditions, the effect of three parameters including short-term aging (asphalt binder storage in the oven), curing time (from construction to placement in the test chamber), and thermal equilibrium time (from placement in the test chamber to the test onset) were investigated on the characteristics of WMA at mid-temperature. To simultaneously examine these three factors, 36 modes were developed to evaluate their effect on the stiffness modulus and fatigue cracking, using the indirect tensile stiffness modulus test (ITSM) and indirect tensile fatigue test (ITFT), respectively. Results of the experiments showed that increasing the time of asphalt binder placement in the oven for 2–6 h significantly increased the stiffness modulus of the mixture, which reduced the fatigue life of the WMA. With increasing the curing time and improving the adhesion between asphalt binder and aggregates, the stiffness modulus and fatigue life of the specimens increased; however, by increasing the thermal equilibrium time, the stiffness modulus and fatigue life of the specimens decreased due to asphalt binder viscoelastic behavior and temperature sensitivity. Results of statistical analyses revealed that short-term aging, curing time, and thermal equilibrium time in laboratory conditions were effective on the stiffness modulus and fatigue life of WMA at a 95% confidence level.

Similar content being viewed by others

References

Chowdhury A, Button JW (2008) A review of warm mix asphalt. Texas Transportation Institute, the Texas A & M University System, College Station, TX

D’Angelo J, Harm E, Bartoszek U, Baumgardner G, Corrigan M, Cowsert J, Harman T, Jamshidi M, Jones W, Newcomb D (2008) Warm-mix asphalt: European Practice Federal Highway Administration Report FHWA-PL-08-007

Ruíz-Ibarra JF, Rondón-Quintana HA, Chaves-Pabón SB (2020) Behavior of a warm mix asphalt containing a blast furnace slag. Int J Civ Eng 18(3):325–334

Topal A, Oner J, Sengoz B, Dokandari PA, Kaya D (2017) Evaluation of rutting performance of warm mix asphalt. Int J Civ Eng 15(4):705–714

Al-Qadi IL, Wang H, Baek J, Leng Z, Doyen M, Gillen S (2012) Effects of curing time and reheating on performance of warm stone-matrix asphalt. J Mater Civ Eng 24(11):1422–1428

Read J, Whiteoak D (2003) The shell bitumen handbook. Thomas Telford, London

Mazumder M, Ahmed R, Hasan M, Lee S-J, Lee M-S (2020) Spectroscopic ellipsometry of asphalt binder: a study of optical constants. Int J Civ Eng 18(3):251–259

Singh B, Kumar P (2020) Viscoelastic and morphological evaluation of aged polymer modified asphalt binders. Int J Civ Eng 18(9):1077–1096. https://doi.org/10.1007/s40999-020-00517-4

Wu S, Li X (2017) Evaluation of effect of curing time on mixture performance of Advera warm mix asphalt. Constr Build Mater 145:62–67

Graziani A, Godenzoni C, Cardone F, Bocci M (2016) Effect of curing on the physical and mechanical properties of cold-recycled bituminous mixtures. Mater Des 95:358–369

Guatimosim FV, Vasconcelos KL, Bernucci LL, Jenkins KJ (2018) Laboratory and field evaluation of cold recycling mixture with foamed asphalt. Road Mater Pavement Des 19(2):385–399

Miljković M, Radenberg M (2015) Characterising the influence of bitumen emulsion on asphalt mixture performance. Mater Struct 48(7):2195–2210

Oruc S, Celik F, Akpinar MV (2007) Effect of cement on emulsified asphalt mixtures. J Mater Eng Perform 16(5):578–583

Fang X, Garcia A, Winnefeld F, Partl MN, Lura P (2016) Impact of rapid-hardening cements on mechanical properties of cement bitumen emulsion asphalt. Mater Struct 49(1–2):487–498

Konrad J-M, Walter J (2001) Influence of curing on the mechanical properties of a dense graded emulsion mix. Road Mater Pavement Des 2(2):181–194

Hamedi GH (2018) Effects of polymeric coating the aggregate surface on reducing moisture sensitivity of asphalt mixtures. Int J Civ Eng 16(9):1097–1107

Son H-J, Kim Y-J, Lim J-K, Kwon S-A, Hong J-C, Shin H-J (2014) Influences of curing time on polymer-modified emulsion used for slurry seal and micro-surfacing mixes. In: Recent developments in evaluation of pavements and paving materials, pp 35–42

Javid AAS, Ghoddousi P, Zareechian M, Korayem AH (2019) Effects of spraying various nanoparticles at early ages on improving surface characteristics of concrete pavements. Int J Civ Eng 17(9):1455–1468

Hamedi GH (2018) Investigating the use of nano coating over the aggregate surface on moisture damage of asphalt mixtures. Int J Civ Eng 16(6):659–669

Walubita LF, Faruk AN, Zhang J, Hu X, Lee SI (2016) The Hamburg rutting test–Effects of HMA sample sitting time and test temperature variation. Constr Build Mater 108:22–28

Zeinali A, Blankenship PB, Mahboub KC (2014) Effect of laboratory mixing and compaction temperatures on asphalt mixture volumetrics and dynamic modulus. Transp Res Rec 2447(1):101–108

Fattah MY, Al Helo KHI, Qasim ZI (2014) Fatigue cracking performance of local superpave asphalt concrete mixtures. Eng Technol J 32(12 Part (A) Engineering):2904–2920

Sebaaly PE, Hajj EY, Piratheepan M (2015) Evaluation of selected warm mix asphalt technologies. Road Mater Pavement Des 16(sup1):475–486

Im S, Zhou F (2015) Laboratory short-term aging protocol for plant-mixed and laboratory compacted samples. Constr Build Mater 89:1–12

Malladi H, Ayyala D, Tayebali AA, Khosla NP (2014) Laboratory evaluation of warm-mix asphalt mixtures for moisture and rutting susceptibility. J Mater Civ Eng 27(5):04014162

Pasandín A, Pérez I (2014) Effect of ageing time on properties of hot-mix asphalt containing recycled concrete aggregates. Constr Build Mater 52:284–293

Yi MW, Wang JC, Feng XD (2014) Effect of ultraviolet light aging on fatigue properties of asphalt. In: Key engineering materials. Trans Tech Publ, pp 125–129

Ziari H, Moniri A, Bahri P, Saghafi Y (2019) The effect of rejuvenators on the aging resistance of recycled asphalt mixtures. Constr Build Mater 224:89–98

AASHTO (2011) Standard specifications for transportation materials and methods of sampling and testing

British Standard (2018) Bituminous mixtures, test methods-part 24: resistance to fatigue-BS EN 12697-24:2018, London, UK

British Standards (2018) Bituminous mixtures—test methods-part 26: stiffness-BS EN 12697-26:2018, London, UK

Hurley GC, Prowell BD (2005) Evaluation of Sasobit for use in warm mix asphalt. NCAT Rep 5(6):1–27

Jamshidi A, Hamzah MO, You Z (2013) Performance of warm mix asphalt containing Sasobit®: state-of-the-art. Constr Build Mater 38:530–553

Kristjansdottir O (2006) Warm mix asphalt for cold weather paving. University of Washington Seattle, WA

Institute A (1997) Mix design methods for asphalt concrete and other hot-mix types, vol 2. Lexington, Asphalt Institute

Kim YR (2008) Modeling of asphalt concrete

Roberts FL, Kandhal PS, Brown ER, Lee D-Y, Kennedy TW (1991) Hot mix asphalt materials, mixture design and construction

ASTM D4123-82 (1995) Standard test method for indirect tension test for resilient modulus of bituminous mixtures (withdrawn 2003). ASTM International, West Conshohocken, PA

Harvey JT, Deacon JA, Tsai B-W, Monismith CL (1995) Fatigue performance of asphalt concrete mixes and its relationship to asphalt concrete pavement performance in California. University of California, Berkeley, Institute of Transportation Studies, Asphalt Research Program, CAL/APT Program

Huang YH (1993) Pavement analysis and design

Hamedi GH, Ghalandari Shamami K, Mazhari Pakenari M (2020) Effect of ultra-high-molecular-weight polyethylene on the performance characteristics of hot mix asphalt. Constr Build Mater 258:119729

Behbahani H, Najafi Moghaddam Gilani V, Salehfard R, Safari D (2020) Evaluation of fatigue and rutting behaviour of hot mix asphalt containing rock wool. Int J Civ Eng. https://doi.org/10.1007/s40999-020-00532-5

Nguyen VH, Le VP (2019) Performance evaluation of sulfur as alternative binder additive for asphalt mixtures. Int J Pavement Res Technol 12(4):380–387. https://doi.org/10.1007/s42947-019-0045-9

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mazhari Pakenari, M., Hamedi, G.H. Investigating the Effective Laboratory Parameters on the Stiffness Modulus and Fatigue Cracking of Warm Mix Asphalt. Int J Civ Eng 19, 685–698 (2021). https://doi.org/10.1007/s40999-020-00592-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40999-020-00592-7