Abstract

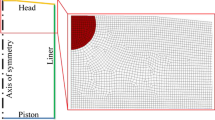

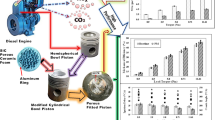

In the present work, computational fluid dynamics approach is adopted to study the possibility of using porous media in combustion and emission in a single-cylinder four-stroke spark ignition engine. The combustion behavior inside the engine without and with application of porous media is studied. The analysis with application of PM signifies enhanced combustion behavior. The compression ratio is kept at 7. Two different types of fluid computational domains are considered, namely, without and with PM. The three-dimensional modeling, meshing and simulations of the combustion chambers are performed with the ANSYS 17.1-FLUENT software. The k–ε turbulence model, the premixed combustion model and the spark ignition model are used in the study. The parameters to be analyzed are the variation of cylinder pressure, temperature and turbulence at different crank angles. The results of the computational work without PM are validated with the experimental work, which is executed on the research engine setup operated in SI mode. The work is performed at different engine loads by varying the engine torque, viz. 6 Nm (25%), 12 Nm (50%), 18 Nm (75%) and 24 Nm (100%) along with the no-load condition. The analyses of the results indicate that the peak value of total pressure (1,986,868.99 Pa) and average value of total temperature (632.63 K) with PM at 100% load are lower than without PM (1,992,314.50 Pa and 604.81 K). The concentrations of NOX emissions are significantly reduced by the use of PM for all the loads. The percentage reductions in NOX emissions at no load, 25%, 50%, 75% and 100%, are found to be 2.5%, 11.1%, 9.4%, 9% and 2.12%, respectively.

Similar content being viewed by others

Notes

Instruction Manual, Computer Based Four Stroke Single Cylinder Variable Compression Ratio Multifuel Engine with Eddy Current Dynamometer, Tech-Ed Equipment Company, Bengaluru, 560072, Karnataka, India

Abbreviations

- b :

-

Inertial resistance (m−1)

- B :

-

Bore (mm)

- c p :

-

Specific heat (J/kg)

- D :

-

Diameter (mm)

- h :

-

Clearance height (mm)

- H :

-

Height of the computational domain (mm)

- ƩH :

-

Heat of combustion (J/kg)

- k :

-

Thermal conductivity (W/m K)

- K :

-

Permeability (m2)

- l 1/2 :

-

Characteristics length of the effective pore diameter (mm)

- L :

-

Height of the PM (mm)

- P :

-

Cylinder pressure (Pa)

- r c :

-

Compression ratio

- Q :

-

Heat release in a process (J/°)

- s :

-

Laminar flame speed (cm/s)

- S :

-

Sphericity of the pores

- T :

-

Adiabatic temperature (K)

- V :

-

Cylinder volume (m3)

- α, β :

-

Burned gas diluents fraction

- \(\gamma\) :

-

Specific heat capacity ratio

- δ :

-

Laminar flame thickness (mm)

- η :

-

Thermal efficiency

- θ :

-

Crank angle (°)

- µ :

-

Dynamic fluid viscosity (N s/m2)

- ρ :

-

Fluid density (kg/m3)

- Ф :

-

Mean equivalence ratio

- \(\nu\) :

-

Kinematic viscosity (m2/s)

- ϕ :

-

Porosity

- p :

-

Pore

- m :

-

Mean

- u :

-

Unburnt

- s, g :

-

Solid and fluid phase

- ATDC:

-

After top dead center (°)

- BTDC:

-

Before top dead center (°)

- BDC:

-

Bottom dead center

- C:

-

Computational

- CAD:

-

Crank angle degree (°)

- CI:

-

Compression ignition

- E:

-

Experimental

- HRR:

-

Heat release rate (J/°)

- ICE:

-

Internal combustion engine

- PM:

-

Porous media

- PPI:

-

Pore per inch

References

Bejan A (2004) Convection heat transfer, 3rd edn. Wiley, New York

Ceper BA, Yildiz M, Akansu SO, Kahraman N (2016) Performance and emission characteristics of an IC engine under SI, SICAI and CAI combustion modes. Int J Power Energy 4:1–8

Chidambaram K, Thulasi V (2016) Two zone modeling of combustion, performance and emission characteristics of a cylinder head porous medium engine with experimental validation. Multidiscip Model Mater Struct 12(3):495–513

Das S, Kumar S, Debnath BK (2015) CFD analysis of combustion in a Wankel Engine in the presence of Porous Media. In: Poster presentation in the 5th international conference on advances in energy research (ICAER), IIT Bombay, India

Durst F, Weclas M (2001) A new type of internal combustion engine based on the porous medium combustion technique. Proc Inst Mech Eng D J Automob Eng 215:63–81

Ergun S (1952) Fluid flow through packed columns. Chem Eng Prog 48(2):89–94

Fluent 6.3 Documentation (2010) ANSYS 17.1-FLUENT, Inc. http://my.fit.edu/itresources/manuals/fluent6.3/help/html/tg/main_pre.htm

Fukang M, Changlu Z, Fujun Z, Zhenfeng Z, Shuanlu Z (2015) Effects of scavenging system configuration on in-cylinder air flow organization of an opposed-piston two-stroke engine. Energies 8(1):5866–5884

Hanamura K, Bohda K, Miyairp Y (1997) A study of super-adiabatic combustion engine. Energy Convers Manag 38:1259–1266

Heywood J (1988) Internal combustion engine fundamentals. McGraw-Hill Book Company, New York

Jamalabadi MYA, Rajabzadeh M, Hooshmand P (2015) Effect of fuel inject angle on the thermal behavior of a 2D axisymmetric non-premixed methane–air flame in vertical cylinder filled by porous media. Int J Energy Eng 5(1):1–8

Jugjai S, Polmart N (2003) Enhancement of evaporation and combustion of liquid fuels through porous media. Exp Therm Fluid Sci 27(8):901–909

Krishna K, Kumar P, Reddy VK, Rao PV, Gugulothu R (2016) A review of porous-media combustion technology applied to IC engine. Int J Eng Res (IJER) 5(2):491–494

Liu H, Xie M, Wu D (2009) Thermodynamic analysis of the heat regenerative cycle in porous medium engine. Energy Convers Manag 50(1):297–303

Mohammadi A, Jazayeri A, Ziabasharhagh M (2012) Numerical simulation of combustion with porous medium in IC engine. Int J Automob Eng 2(4):228–241

Mujeebu M, Abdullah MZ, Mohammad AA, Bakar MZ (2010) Trend in modelling of porous media combustion. J Prog Energy Combust Sci 2(1):1–24

Nield DA, Bejan A (2006) Convection in porous media, 3rd edn. Springer, Berlin

Park CW, Kaviany M (2002) Evaporating combustion affected by in cylinder reciprocating porous regenerator. ASME J Heat Transf 124(2):184–194

Patel AB, Patel VR, Ambaliya AM (2015) Study of effect of porous media combustion chamber on diesel engine performance and emission: technical review. Int J Eng Res Technol (IJERT) 3(2):78–91

Polasek M, Macek J (2003) Homogenization of combustion in cylinder of CI engine using porous medium. SAE Paper 2003-01-1085

Shaahangian N, Ghoje J (2010) Investigation of the interaction between diesel spray and porous medium. In: 17th Australian fluid mechanics conference, 5–9th December, Auckland, New Zealand

Shahangian N, Ghojel J (2010) Investigation of the interaction between diesel spray and porous medium. In: 17th Australian fluid mechanics conference, Auckland

Shi JR, Xie MZ, Liu H (2011) Two-dimensional numerical study of combustion and heat transfer in porous media combustor-heater. Proc Combust Inst 33(2):3309–3316

Singh B, Singh C (2012) Analysis of vortex motion in porous media. J Electron Cool Therm Control 2:32–34

Stone R (1997) Introduction to internal combustion engines. Society of Automotive Engineers Inc., Warrendale

Suhas BG, Shivaprasad KV, Kumar GN (2013) Computational and experimental investigation of NOx emission of hydrogen blend on a constant speed gasoline engine. Int J Theor Appl Res Mech Eng 2(4):121–125

Trimis D, Wawrzinek K (2004) Flame stabilization of highly diffusive gas mixtures in porous inert media. J Comput Appl Mech 5(2):367–381

Weclas M (2005) Potential of porous-media combustion technology as applied to internal combustion engines. J Thermodyn 2010(1):1–39

Yuan SW, Finkelstein AB (1956) Laminar pipe flow with injection and suction through a porous wall. Trans Am Soc Mech Eng 78(4):719–724

Zhao FQ, Lai MC (1995) The spray characteristics of automotive port fuel injection—a critical review. SAE Technical Paper-950506

Zhou L, Xie MZ, Luo KH (2014) Numerical study of heat transfer and combustion in IC engine with a porous media piston region. Appl Therm Energy 65(1):597–604

Acknowledgements

The authors wish to extend their sincere thanks to Santosh Kumar, Senior Works Manager of TECH-ED Equipment Company, Bangalore, for his support and required guidance in performing the experimental works. Further, sincere gratitude also goes to Nur Alom, Trainee Teacher of Mechanical Engineering, for his assistance in learning ANSYS 17.1-FLUENT.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sharma, D., Debnath, B.K. Computational Investigation of Porous Media Combustion Technology in Spark Ignition Engine. Iran J Sci Technol Trans Mech Eng 44, 783–797 (2020). https://doi.org/10.1007/s40997-019-00285-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40997-019-00285-0