Abstract

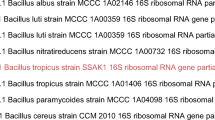

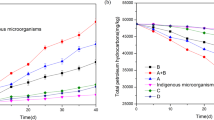

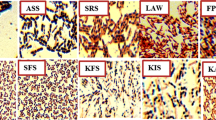

In the perspective of the threats to environment associated with petroium-derived synthetic plastics, there is a critical need to traverse biologically degradable polymeric material. Biologically synthesized polyhydroxyalkanoates are the most promising candidates to be used as bioplastic. Keeping in view the ecofriendly nature of bioplastics, the current study was designed to explore contaminated soil samples for bioplastic producing bacterial strains and use organic wastes as a sole carbon source to reduce cost of bioplastic production. Contaminated soil samples from various areas of Peshawar, Charsada and Dargai were screened for bioplastic producing bacterial strains by using primary stain Sudan black and confirmatory stain Nile blue A. The growth medium and physical parameters were optimized for efficient producers. A variety of organic wastes; fruits and vegetable wastes were used as carbon source in E2 medium under submerged fermentation in 1L flasks for bioplastic production by optimized higher yielding bacterial strain KHA-S-03. E.coli K12 and Ralstonia eutropha MTCC1285 were used as negative and positive control respectively. KHA-S-03 was molecularly identified to be Bacillus megaterium SFK by 16srDNA sequencing and Pha C gene of identified strain was sequenced and phylogenetically analyzed, this strain was able to utilize organic wastes as sole carbon source under optimized condition of incubation time 48 h, pH 7, temperature 37 °C, substrate concentration 5%, C/N ratio 8:1, agitation rate 200 rpm, inoculum size of 5% and nitrogen sources (NH4)2SO4 and NH4Cl. For efficient downstreaming, among various solvents tested, ethylene carbonate (nontoxic solvent) was found to have efficiency near to chloroform (toxic solvent).

Similar content being viewed by others

Abbreviations

- PHA:

-

Polyhydroxyalkanoate

- sclPHA:

-

Small chain length

- mclPHA:

-

Medium chain length

- lclPHA:

-

Long chain length

- N:

-

Nitrogen

- C:

-

Carbon

References

Amass W, Tighe B (1998) A review of biodegradable polymers: uses, current developments in the synthesis and characterization of biodegradable polyesters, blends of biodegradable polymers and recent advances in biodegradation studies. Polym Intern 47:89–144

Anderson AJ, Dawes EA (1990) Occurrence, metabolism, metabolic role, and industrial uses of bacterial polyhydroxyalkanoates. Microbiol Rev 54:450–472

Aramavash A, Zavareh MF, Banadkuki N (2018) Comparison of different solvents for extraction of polyhydroxyalkanoates from Cupriavidus nector. Eng Life Sci 18(1):20–28

Bayari S, Severcan F (2005) FTIR study of bidegradable ioploymers: p(3HB, P(3HB-co-4HB)and P(3HB-co-3HV). J Mol Struct 744:529–534

Bhagowati P, Pradhan S, Dash HR, Das S (2015) Production, optimization and characterization of polyhydroxybutyrate, a biodegradable plastic by Bacillus spp. Biosci Biotechnol Biochem 79:1454–2146

Chanprateep S (2010) Current trends in biodegradable polyhydroxyalkanoates. J Biosci Bioeng 110:621–632

Colin R, Kristiansen B (2004) Microbial polyhydroxyalkanoates, polysaccharides and lipids, 2nd edn. Cambridge University Press, Cambridge, pp 325–348

Dionisi D, Majone M, Papa V, Beccari M (2004) Biodegradable polymers from organic acids by using activated sludge enriched by aerobic periodic feeding. Biotechnol Bioeng 85:569–579

Grothe E, Mou-Yong C (1999) Fermentation optimization for production of poly(h-hydroxybutyric acid) microbial thermoplastic. Enzym Microbe Technol 25:132–141

Holt JG, Krieg NR, Sneath PA, Staley JT and Williams ST (1993) Bergey‘s manual of determinative bacteriology. William and Wilkins, MD pp 559-564

Hungund B, Shyama V, Patwardhan P, Saleh A (2013) Production of polyhydroxyalkanoate from Paenibacillus durus BV-1 isolated from oil mill soil. J Microbiol Biotechnol 5:013–017

Israni N, Shivakumar S (2013) Combinatorial screening of hydrolytic enzyme/s and PHA producing Bacillus spp. for cost effective production of PHAs. Int J Pharma Bio Sci 4:934–945

Jiang Y, Songa X, Gonga L, Li P, Dai C, Shao W (2008) High poly(βhydroxybutyrate) production by Pseudomonas fluorescens A2a5 from inexpensive substrates. Enz Microbial Technol 42:167–172

Kanophorn S, Poonsuk P (2007) Nutrient optimization for the production of polyhydroxybutyrate from halotolerant photosynthetic bacteria under aerobic dark conditions. Electron J Biotechnol 3:707–717

Karana E (2012) Characterization of ‘Natural’ and ‘High-Quality’ materials to improve perception of bioplastics. J Clean Product 37:316–325

Keenan T, Tanenbaum S, Stipanovic J, Nakas P (2004) Production and characterization of poly-beta-hydroxyalkanoate copolymers from Burkholderia cepacia utilizing xylose and levulinic acid. Biotechnol Prog 20:1697–1704

Kumbhakar S, Singh K, Vidyarthi S (2012) Screening of root nodule bacteria for the production of polyhydroxyalkanoate (PHA) and the study of parameters influencing the PHA accumulation. Afr J Biotechnol 11:7934–7946

Kunasundari B, Sudesh K (2011) Isolation and recovery of polyhydroxyalkanoates. Exp Polym Lett 5:620–634

Lafferty RM and Heinzle E (1978) Cyclic carbonic acid esters as solvents for poly-(beta)- hydroxybutyric acid. Patent, US; 4,101,533

Law JH, Slepecky A (1961) Assay of poly-βhydroxybutyric acid. J Bacteriol 82:33–36

Lee SY (1996) Plastic bacteria? Progress and prospects for polyhydroxyalkanoate production in bacteria. Trends Biotechnol 14:431–438

Lemos PC, Serafim LS, Reis M (2006) Synthesis of polyhydroxyalkanoates from different short-chain fatty acids by mixed cultures submitted to aerobic dynamic feeding. J Biotechnol 122:226–238

Luengo JM, Garcia B, Sandoval A, Naharro G, Olivera ER (2003) Bioplastics from Microorganisms. Curr Opin Microbiol 6:251–260

Mohapatra S, Sarkar B, Samantaray DP, Daware A, Maity S, Pattnaik S, Bhattacharjee S (2017) Bioconversion of fish solid waste into PHB using Bacillus subtilis based submerged fermentation process. Environ Technol 1–810:1058–1080

Montiel Jarrilo G, Carrel J, Suarez Ojeda ME (2017) Enrichment of mixed microbial Culture for polyhydroxyalkanoates production effect of pH and N and P concentrations. Sci Total Environ 583:300–307

Musa H, Bolanle BB, Kasim FH, Arbain D (2016) Screening and production of polyhydroxybutyrate (PHB) by bacterial strains isolated from rhizosphere soil of groundnut plants. Sains Malays 45(10):1469–1476

Nayak PK, Mohanty AK, Gaonkar T, Kumar A, Bhosle SN, Garg S (2013) Rapid Identification of Polyhydroxyalkanoate accumulating members of Bacillales using internal primers for phaC Gene of Bacillus megaterium. Int Sch Res Notices. https://doi.org/10.1155/2013/562014

Peelman N, Ragaert P, de Meulenaer B, Adons D, Peeters R, Cardon L (2013) Application of bioplastics for food packaging. J Trnds Food Sci Tech 32:128–141

Priyanka S, Bijender K (2015) Production and characterization of poly-3-hydroxybutyrate from Bacillus cereus PS 10. Int J Biol Macromol 81:241–248

Reddy VST, Mahmood KS (2009) Production of PHB and P(3HBco3HV) biopolymers of Bacillus megaterium strain isolated from municipal sewage sludge. W J Microbiol Biotechnol 25:391397

Reddy C, Ghai R, Rashmi KV (2003) Polyhydroxyalkanoates: an overview. Bioresour Tech 87:137–146

Sabra W, Abou-Zeid D (2008) Improving feeding strategies for maximizing polyhdroxybutyrate yield by Bacillus megaterium. Res J Microbiol 3:308–318

Sajida M, Nazia J (2015) Characterization of polyhydroxyalkanoates produced by contaminated soil bacteria using wastewater and glucose as carbon sources. Trop J Pharm Res 14(9):1605–1611

Sasidharan RS, Bhat SG, Chandrasekaran M (2015) Biocompatible polyhydroxybutyrate (PHB) production by marine Vibrio azureus BTKB33 under submerged fermentation. Ann Microbiol 65:455–465

Serafim L, Lemos C, Maria A, Reis M, Ana M (2014) The influence of process parameters on the characteristics of Polyhydroxyalkanoates produced by mixed cultures. Macromol Biosci 8(4):355–366

Shaaban T, Attia M, Turky S, Mowafy E (2012) Production of some biopolymers by some selective Egyptian soil bacterial isolates. J Appl Sci Res 8:94–105

Shreya S, Anil K (2021) Production and characterization of polyhydroxyalkanoates from industrial wastes using soil bacterial isolates. Braz J Micobiol 52(2):715–726

Tajima K, Igari T, Nishimura D, Nakamura M, Satoh Y, Munekata M (2003) Isolation and characterization of Bacillus sp. INT005 accumulating polyhydroxyalkanoate (PHA) from gas field soil. J Biosci Bioeng 95:77–81

Van-Thuoc D, Quillaguaman J (2014) Improving culture conditions for poly(3- hydroxybutyrate-co-3-hydroxyvalerate) production by Bacillus sp. ND153, a bacterium isolated from a mangrove forest in Vietnam. Ann Microbiol 64:991–997

Wong PA, Chua HW, Lawford HG, Yu PH (2002) Production of specific copolymers of polyhydroxyalkanoates from industrial waste. Appl Biochem Biotechnol 98–100:655–662

Yilmaz M, Beyatli Y (2005) Poly beta-hydroxybtyrate (PHB) production by a bacillus cereus M5 strain in sugar beet molasses. Zuckerindustrie 2005(130):109–112

Yu-Hong W, Wei-Chuan C, Chin-Kuei H, Ho-Shing W, Yi-Ming S, Chi-Wei L, Om-Murugan J (2011) Screening and evaluation of polyhydroxybutyrate-producing strains from indigenous isolate cupriavidus taiwanensis strains. Int J Mol Sci 12:252–265

Acknowledgements

The researchers are thankful to the Centre of Biotechnology and Microbiology University of Peshawar, Shaheed Benazir Bhutto Women University Peshawar, and Department of Physics for technical support.

Funding

Available resources in labs and authors financially contributed together to complete this work.

Author information

Authors and Affiliations

Contributions

Sumaira contributed to experimental analysis and molecular studies; SA contributed to Molecular studies; AI hepled in draft preparation and writing.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflict of interest to declare.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sumaira, Afzal, S. & Islam, A. Optimization of Soil Bacteria for Bioplastic Production Using Organic Wastes as a Substrate Under Submerged Fermentation. Iran J Sci 47, 375–387 (2023). https://doi.org/10.1007/s40995-023-01431-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40995-023-01431-9