Abstract

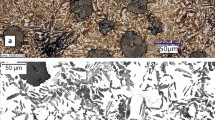

This work compares alternatives for the production of high ductility ADI, austempered from an intercritical austenitizing temperature range, with a microstructure of ferrite + ausferrite. Different initial microstructures were selected, including ferrite, pearlite, pearlite + ferrite, martensite and ausferrite. The samples were austenitized within the intercritical zone (795 °C) for different times (up to 12 h) and then austempered at 350 °C. The evolution of the formation and distribution of ferrite and austenite during the austenitizing process for the different initial microstructures was studied. For the selected austenitizing temperature, all of the initial microstructures produced 30% ferrite (70% ausferrite) in the final microstructure (after 12 h). The mechanical properties depend upon the distribution and refinement of the ferrite and ausferrite areas. Spheroidized carbides from pearlite are not completely dissolved during intercritical austenitizing for 2 h. Graphite nodules are an important source of carbon for the austenite formed from starting microstructures of ferrite, pearlite + ferrite and pearlite with grain boundaries being the main pathway for carbon diffusion. Austenitizing started away from the graphite nodules at eutectic cell boundaries due to Si segregation. For starting microstructures of ferrite, pearlite and pearlite + ferrite, a homogeneous distribution of austenite does not occur. Rather, it is concentrated on eutectic cell boundaries and ferrite grain boundaries with large areas of ferrite around the graphite nodules. For starting microstructures of martensite and ausferrite, carbon is evenly distributed and quickly dissolved, resulting in a homogeneous distribution of austenite and ferrite with the best combination of strength and ductility.

Similar content being viewed by others

References

W.L. Guesser, L.C. Guedes, R.R. Vieira, The influence of hydrogen on the fracture mechanism and mechanical properties of blackheart malleable and ductile irons, in 59th World Foundry Congress (São Paulo, 1992), pp. 22.4–22.11

H. Santos, Mecanismos de fratura de ferro nodular austemperado a partir da zona crítica. Master Thesis, UDESC, (Brasil, 2010)

D. Rousiere, J. Aranzabal, Development of mixed (ferrite–ausferitic) structures for spheroidal graphite irons. Metall. Sci. Metall. 18(11), 24–29 (2000)

W.L. Guesser, E. Franco, C. Lussoli, C.E. Costa, Ferro nodular austemperado a partir da zona crítica, in 14th Anual Foundry Congress ABM-ABIFA, (São Paulo, 2009)

M. Erdogan, V. Kilicli, B. Demir, Transformation characteristics of ductile iron austempered from intercritical austenitizing temperature ranges. J. Mater. Sci. 44(5), 1394–1403 (2009)

E. Franco, C.E. Costa, W.L. Guesser, Estudo dos parâmetros de austenitização para fabricação do ferro nodular austemperado usinável, in 8th Congreso Iberoamericano de Ingenieria Mecânica (Cusco Perú, 2007)

G. Jolley, Segregation in nodular iron and its influence on mechanical properties. Br. Foundrym. 3, 79–92 (1967)

C.L. Lopes, Estudo da influência das temperaturas de austenitização nas propriedades mecânicas do ferro nodular austemperado a partir da zona crítica. Master Thesis, UDESC, (Brasil, 2009)

R. Hummer, W. Westerholt, Untersuchungen zur Wärmebehandlung von Gusseisen mit Kugelgraphit unter besonderer Berücksichtigung der Herstellung von GGG-50. Giesserei-Praxis, 1979, no 1/2, pp. 15–20

W.L. Guesser, E. Melleras, C. Cabezas, I. Masiero, Avaliação da qualidade metalúrgica em ferros fundidos nodulares e cinzentos, in 15th CONAF and BRICS Forum, ABIFA, (São Paulo, 2011)

C.L. Lopes, Estudo da influência da microestrutura na cinética de austenitização na zona crítica e propriedades mecânicas de ferros nodulares austemperados duais. PhD Thesis, UFSC, (Brasil, 2014)

E. Franco, C.E. Costa, J. Stahlschmidt, W.L. Guesser, Otimização dos parâmetros de austenitização de um ferro nodular austemperado a partir da zona crítica. Tecnol. Metal. Mater. Miner 6(3), 142–146 (2010). https://doi.org/10.4322/tmm.00603004

W.L. Guesser, Fragilização por hidrogênio em ferros fundidos nodulares e maleáveis pretos. PhD Thesis, USP, (São Paulo, 1993). http://www.teses.usp.br/teses/disponiveis/3/3133/tde-04092019-141731/. Accessed 26 June 2019

Acknowledgements

The experiments reported in this paper were conducted in partnership with Tupy Foundry and Santa Catarina Federal University—UFSC.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This paper is an invited submission to IJMC selected from presentations at the 2nd Carl Loper 2019 Cast Iron Symposium held September 30 to October 1, 2019, in Bilbao, Spain.

Rights and permissions

About this article

Cite this article

Guesser, W.L., Lopes, C.L. & Bernardini, P.A.N. Austempered Ductile Iron with Dual Microstructures: Effect of Initial Microstructure on the Austenitizing Process. Inter Metalcast 14, 717–727 (2020). https://doi.org/10.1007/s40962-019-00397-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-019-00397-y