Abstract

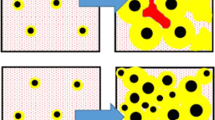

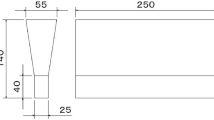

S and O have a high capacity to react with nodularizing elements, while the resulting products could be useful as nucleation sites for graphite. Any consumption of these elements could change a nodular to compacted or just lamellar morphologies. The main objective is to evaluate the effects of inoculation and S- or O-addition after Mg-treatment and inoculation on the sensitivity of high Si ductile iron, solidified in mold media without S or O contribution, to graphite degeneration in the surface layer compared to the body of the casting. Mg-treated and ladle-inoculated cast iron is used, containing 0.031%Mgres, 3.37%C, 3.44%Si, 0.44%Mn, for 4.43% carbon equivalent. FeS2 or Fe2O3 powder is placed on the bottom of a standard ceramic cup, used in thermal analysis (7.3 mm cooling modulus). Structure characteristics are analyzed from the section of the ceramic cup samples. The skin thickness has different values, depending on the graphite nodularity or shape factors or matrix evaluation results. Inoculation has a beneficial effect on the graphite phase characteristics: with only 3% higher nodularity in the casting body, this treatment is very efficient to decrease the skin effect thickness. A stronger degenerative effect of S on the graphite morphology was found, compared to the stoichiometric equivalent O-addition after inoculation, not only in the casting but also as the thickness of the skin. At higher S- or O-addition, the casting skin thickness increased, but at different levels: from two to four times higher after S-addition, and up to 30% higher after O-addition.

Similar content being viewed by others

References

I. Riposan, T. Skaland, Modification and inoculation of cast iron, in ASM, Cast Iron Science and Technology Handbook, ed. by D.M. Stefanescu, pp 160–176 (2017)

I. Riposan, M. Chisamera, S. Stan, T. Skaland, M.I. Onsoien, AFS Trans. 109, 1151–1162 (2001)

I. Riposan, M. Chisamera, S. Stan, C. Hartung, D. White, Mater. Sci. Technol. 26(12), 1439–1447 (2010)

I. Riposan, M. Chisamera, S. Stan, Mater. Sci. Forum 925, 3–11 (2018)

A. Sommerfeld, B. Tonn, Int. J. Metalcasting 3(4), 39–47 (2009)

B.B. Gundlach, AFS Metalcasting Congr., Atlanta, GA, USA, Paper 08-158 (2008)

J.A. Campbell, Met. Mater. Trans. B. 40(6), 786–801 (2009)

G. Alonso, D.M. Stefanescu, M. Larranaga, E. De la Fuente, R. Suarez, AFS Trans. 124, 124–134 (2016)

M.H. Jacobs, T.J. Law, D.A. Melford, M.J. Stowell, Metals Technol., 490–500 (1974); 98–108 (1976)

T. Skaland, Nucleation Mechanism in Ductile Iron. Doctoral Thesis, Metallurgisk Institutt, Trondheim, Norway (1992)

J.K. Solberg, M.I. Onsoien, Mater. Sci. Technol. 17(10), 1238–1242 (2001)

V. Igoraski, S. Okade, Int. J. Cast Metal Res. 11(2), 83–88 (1998)

H. Nakae, Y. Igarashi, Mater. Trans. 43(11), 2826–2831 (2002)

G. Alonso, D.M. Stefanescu, P. Larranaga, R. Suarez, E. De la Fuente, AFS Trans., 125, Paper 17-031 (2017)

I. Riposan, M. Chisamera, S. Stan, P. Toboc, G. Grasmo, D. White, C. Ecob, C. Hartung, J. Mater. Eng. Perform. 20(1), 57–64 (2011)

I. Riposan, M. Chisamera, Giesserei Praxis, Issue 9/10, 155–162 (1991) and Casting, Forging and Heat Treatment (Japan), Issue 547, 17–23 (1993)

M. Chisamera, I. Riposan, S. Stan, M. Barstow, D. Kelly, R.L. Naro, AFS Trans. 104, 581–588 (1996)

M. Chisamera, I. Riposan, S. Stan, M. Barstow, D. Kelly, R.L. Naro, AFS Trans. 110, 851–860 (2002)

M. Chisamera, I. Riposan, S. Stan, M. Barstow, D. Kelly, R.L. Naro, AFS Trans. 111, 869–883 (2003)

I. Riposan, M. Chisamera, S. Stan, Int. J. Metalcasting 7(1), 9–20 (2013)

N. Ivan, M. Chisamera, I. Riposan, Int. J. Metalcasting 6(4), 61–69 (2012)

N. Ivan, M. Chisamera, I. Riposan, S. Stan, AFS Trans. 121, 379–390 (2013)

R. Danko, M. Gorny, M. Holtzer, S. Zymankowska-Kumon, ISIJ Int. 54(6), 1288–1293 (2014)

S. Boonmme, D.M. Stefanescu, AFS Trans. 121, 449–459 (2013)

J. Qing, S. Lekakh, V. Richards, AFS Trans. 121, 13–120 (2013)

D. Anca, Research on the loss modifying effect in the superficial layer phenomenon of the iron castings. Ph.D. Thesis, POLITEHNICA University of Bucharest, Romania, 2014

T. Thielemann, Giessereitechnik, Issue 1, 16–24 (1970)

S. Stan, I. Riposan, M. Chisamera, I. Stan, J. Mater. Eng. Perform. 28(1), 278–286 (2019)

Acknowledgements

The work has been funded by the Sectoral Operational Programme Human Resources Development 2007–2013 of the Romanian Ministry of Labour, Family and Social Protection through the Financial Agreement POSDRU/107/1.5/S/76903. The authors would like to recognize and thank Michael Barstow (Consultant) for reviewing and editing this paper.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This paper is an invited submission to IJMC selected from presentations at the 2nd Carl Loper 2019 Cast Iron Symposium held September 30 to October 1, 2019, in Bilbao, Spain.

Rights and permissions

About this article

Cite this article

Anca, D., Chisamera, M., Stan, S. et al. Graphite Degeneration in High Si, Mg-Treated Iron Castings: Sulfur and Oxygen Addition Effects. Inter Metalcast 14, 663–671 (2020). https://doi.org/10.1007/s40962-019-00385-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-019-00385-2