Abstract

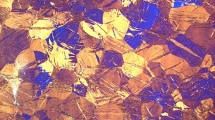

Microstructure, hardness and biocorrosion properties of ZXM220–xSr alloys (x = 0, 0.2, 0.4, 0.8 and 1 wt%) were investigated, and the results were compared with each other. Microstructural characterizations were carried out by XRD, optical and scanning electron microscopes. Biocorrosion properties were determined by immersion and electrochemical corrosion tests, performed in a simulated body fluid solution at 37 °C. Compared to the Sr-free alloy, Sr-bearing alloys exhibited a smaller grain size and a higher volume fraction of second-phase particles. The hardness of the alloy was also gradually improved by increasing Sr additions. Biocorrosion properties of the alloy significantly improved by 0.2 wt% Sr addition, and these properties deteriorated with higher additions of Sr due to the strong microgalvanic effect of coarse second-phase particles. Therefore, the ZXM220–0.2Sr alloy can be regarded as a promising candidate for a new biodegradable implant material due to the optimum results of mechanical and biocorrosion properties.

Similar content being viewed by others

References

M.-S. Song, R.-C. Zeng, Y.-F. Ding, R.W. Li, M. Easton, I. Cole, N. Birbilis, X.-B. Chen, J. Mater. Sci. Technol. 35, 535 (2019)

A. Elsayed, E. Vandersluis, S. Lun Sin, C. Ravindran, Int. J. Met. 11, 749 (2017)

M.P. Staiger, A.M. Pietak, J. Huadmai, G. Dias, Biomaterials 27, 1728 (2006)

Z. Li, X. Gu, S. Lou, Y. Zheng, Biomaterials 29, 1329 (2008)

C.H. Caceres, G.E. Mann, J.R. Griffiths, Metall. Mater. Trans. A 42, 1950 (2011)

S. Cai, T. Lei, N. Li, F. Feng, Mater. Sci. Eng., C 32, 2570 (2012)

H.R. Bakhsheshi-Rad, M.H. Idris, M.R.A. Kadir, S. Farahany, Mater. Des. 33, 88 (2012)

A. Incesu and A. Gungor, Int. J. Met. (2019)

J.C. Gao, S. Wu, Y. Wang, L.Y. Qiao, Mater. Sci. Forum 610, 942–945 (2009)

E. Zhang, D. Yin, L. Xu, L. Yang, K. Yang, Mater. Sci. Eng., C 29, 987 (2009)

H. Lai, J. Li, J. Li, Y. Zhang, Y. Xu, J. Mater. Sci. Mater. Med. 29, 87 (2018)

D. Ke, S. Tarafder, S. Vahabzadeh, S. Bose, Mater. Sci. Eng., C 96, 10 (2019)

Y. Li, C. Wen, D. Mushahary, R. Sravanthi, N. Harishankar, G. Pande, P. Hodgson, Acta Biomater. 8, 3177 (2012)

S. Bose, S. Tarafder, S.S. Banerjee, N.M. Davies, A. Bandyopadhyay, Bone 48, 1282 (2011)

M. Cheng, J. Chen, H. Yan, B. Su, Z. Yu, W. Xia, X. Gong, J. Alloys Compd. 691, 95 (2017)

D. Jiang, Y. Dai, Y. Zhang, C. Liu, K. Yu, Mater. Res. Express 6, 056556 (2019)

L. Yan, J. Zhou, Z. Sun, M. Yang, L. Ma, Mater. Res. Express 5, 045401 (2018)

J. Wang, Y. Ma, S. Guo, W. Jiang, Q. Liu, Mater. Des. 153, 308 (2018)

H. Pan, K. Pang, F. Cui, F. Ge, C. Man, X. Wang, Z. Cui, Corros. Sci. 157, 420 (2019)

H.R. Bakhsheshi-Rad, M.H. Idris, M.R. Abdul-Kadir, A. Ourdjini, M. Medraj, M. Daroonparvar, E. Hamzah, Mater. Des. 53, 283 (2014)

H. Zengin, Y. Turen, L. Elen, J. Mater. Eng. Perform 28, 4647–4657 (2019)

ASTM E112-13, Standard Test Methods for Determining Average Grain Size (ASTM International, West Conshohocken, 2013)

T. Kokubo, H. Takadama, Biomaterials 27, 2907 (2006)

A. Atrens, G.-L. Song, M. Liu, Z. Shi, F. Cao, M.S. Dargusch, Adv. Eng. Mater. 17, 400 (2015)

A. A. Nayeb-Hashemi, J. B. Clark, and ASM International, Phase Diagrams of Binary Magnesium Alloys (ASM International, Metals Park, 1988)

H. Zengin, Y. Turen, Mater. Chem. Phys. 214, 421 (2018)

A.S.M. Handbook, Volume 3: Alloy Phase Diagrams, 10th edn. (ASM International, Materials Park, 1992)

G.L. Song, A. Atrens, Adv. Eng. Mater. 1, 11 (1999)

G.R. Argade, S.K. Panigrahi, R.S. Mishra, Corros. Sci. 58, 145 (2012)

N. Birbilis, K.D. Ralston, S. Virtanen, H.L. Fraser, C.H.J. Davies, Corros. Eng., Sci. Technol. 45, 224 (2010)

M. Mandal, A.P. Moon, G. Deo, C.L. Mendis, K. Mondal, Corros. Sci. 78, 172 (2014)

J.W. Chang, L.M. Peng, X.W. Guo, A. Atrens, P.H. Fu, W.J. Ding, X.S. Wang, J. Appl. Electrochem. 38, 207 (2008)

M.E. Turan, Y. Sun, F. Aydin, H. Zengin, Y. Turen, H. Ahlatci, Mater. Chem. Phys. 218, 182 (2018)

G. Song, A. Atrens, D.S. John, X. Wu, J. Nairn, Corros. Sci. 39, 1981 (1997)

M. Liu, P. Schmutz, P.J. Uggowitzer, G. Song, A. Atrens, Corros. Sci. 52, 3687 (2010)

M. Jamesh, S. Kumar, T.S.N. Sankara Narayanan, Corros. Sci. 53, 645 (2011)

H. Li, S. Pang, Y. Liu, L. Sun, P.K. Liaw, T. Zhang, Mater. Des. 67, 9 (2015)

X. Gu, Y. Zheng, S. Zhong, T. Xi, J. Wang, W. Wang, Biomaterials 31, 1093 (2010)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zengin, H. Role of Sr in Microstructure, Hardness and Biodegradable Behavior of Cast Mg–2Zn–2Ca–0.5Mn (ZXM220) Alloy for Potential Implant Application. Inter Metalcast 14, 442–453 (2020). https://doi.org/10.1007/s40962-019-00366-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-019-00366-5