Abstract

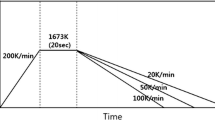

The mold filling rate during evaporative pattern casting was measured in a wide range of molten metal temperatures from 800 to 1450 °C. A polystyrene columnar foam was used as the foamed pattern, and bottom pouring was applied to design the casting. Tin alloy, copper alloy, and cast iron were used as molten metals to vary the molten metal temperature. The mold filling rate increased with increasing molten metal temperature at relatively lower temperatures. In contrast, the mold filling rate decreased with increasing molten metal temperature at high temperatures. These phenomena were verified by in situ observation.

Similar content being viewed by others

References

F. Sonnenberg, Lost Foam Casting Made Simple (American Foundry Society, Schaumburg, 1992)

T. Kobayashi, Y. Kasuya, IMONO 64, 318–324 (1992)

W. Sun, H.E. Littleton, C.E. Bates, Int. J. Cast Met. Res. 16, 549–553 (2003)

T.N. Chakherlou, Y.V. Mahdinia, A. Akbari 32, 162–169 (2011)

C.E. Tseng, D.R. Askeland, Trans. Am. Foundry Soc. 111, 519–527 (1992)

X. Yao, S. Shivkumar, Mater. Sci. Technol. 13, 841–846 (1997)

J. Zhu, I. Ohnaka, T. Ohmichi, K. Mineshita, Y. Yoshioka, J. Jpn. Foundry Eng. Soc. 72, 715–719 (2000)

Y. Liu, S.I. Bakhtiyarov, R.A. Overfelt, J. Mater. Sci. 37, 2997–3003 (2002)

J. Kuo, J. Chen, Y. Pan, W. Hwang, Mater. Trans. 44, 2169–2174 (2003)

D.A. Caulk, M. Barone, Int. J. Metalcast. 2, 29–45 (2008)

D.A. Caulk, Int. J. Metalcast. 3, 7–25 (2009)

S. Koroyasu, J. Jpn. Foundry Eng. Soc. 81, 377–383 (2009)

S. Koroyasu, A. Ikenaga, Mater. Trans. 53, 224–228 (2012)

S. Koroyasu, J. Jpn. Foundry Eng. Soc. 86, 447–453 (2014)

S. Koroyasu, J. Jpn. Foundry Eng. Soc. 88, 192–197 (2016)

M. Khodai, N. Parvin, J. Mater. Proces. Technol. 206, 1–6 (2008)

S.M.H. Mirbagheri, H. Ashuri, N. Varahram, P. Davami, Int. J. Cast Met. Res. 16, 554–565 (2003)

T. Maruyama, K. Katsuki, T. Kobayashi, J. Jpn. Foundry Eng. Soc. 78, 53–58 (2006)

J. Kang, Int. J. Mater. Prod. Technol. 47, 188–199 (2013)

T. Maruyama, G. Nakamura, M. Tamaki, K. Nakamura, Int. J. Metalcast. 11, 77–83 (2017)

T. Kobayashi, Y. Kasuya, IMONO 64, 192–197 (1992)

Author information

Authors and Affiliations

Corresponding author

Additional information

This paper is an invited submission to IJMC selected from presentations at the 73rd World Foundry Congress, held September 23 to 27, 2018, in Krakow, Poland, and has been expanded from the original presentation.

Rights and permissions

About this article

Cite this article

Maruyama, T., Tamaki, M., Nakamura, G. et al. Effect of Molten Metal Temperature on Mold Filling in Evaporative Pattern Casting. Inter Metalcast 13, 611–617 (2019). https://doi.org/10.1007/s40962-019-00310-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-019-00310-7