Abstract

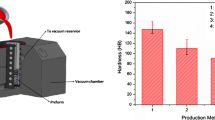

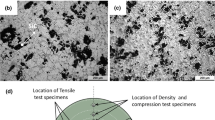

The unresolved production problems including wettability and undesired intermetallic phase formation at the interface of aluminium matrix composites (AMCs) with ceramic reinforcements require a different approach to the subject. Titanium as a reinforcement is a strong candidate to overcome the current problems, without sacrificing beneficial features of conventional AMCs. This study aims to compare microstructural, mechanical and wear properties of bimetal composites manufactured by two different techniques: melt infiltration casting (MIC) and squeeze infiltration (SI). The temperature was set to 730 °C for both production methods. MIC was carried out in an open die with vacuum assistance, while SI was performed in a closed die in an atmospheric environment. Optical microscope, SEM, XRD, EDS, nanoindentation test device and ball-on-disc type tribometer with 3-mm-diameter Al2O3 ball were used for composite characterization. Al, Ti, Si and TiAl3 phases were formed in composite structure for both techniques. Homogeneous and continuous TiAl3 layer was obtained at Al/Ti interfaces. The volume fraction of TiAl3 was 20 times higher in SI than that in MIC due to long interaction time between Al and Ti. The thickness and the hardness of TiAl3 obtained were higher in SI. Abrasive and adhesive wear mechanisms were observed in worn surface examinations. The composite produced by SI showed slightly better performance against wear under the same test conditions. It was exposed to less plastic deformation and abrasive wear than composite produced by MIC. Although initial investment cost was higher, SI appeared to be more advantageous than MIC, considering the applicability in the industry.

Similar content being viewed by others

References

S.J.S. Chelladurai, R. Arthanari, R. Selvarajan, R. Kanagaraj, P. Angappan, Trans. Indian Inst. Met. (2018). https://doi.org/10.1007/s12666-018-1353-5

M. Singh, R.S. Rana, R. Purohit, K. Sahu, Mater. Today Proc. 2, 3697 (2015)

M. Tan, Q. Xin, Z. Li, B.Y. Zong, J. Mater. Sci. 6, 2045 (2001)

D.L. Zalensas, Aluminum Casting Technology, 2nd edn. (American Foundry Society, Schaumburg, 1997)

S. Bao, K. Tang, A. Kvithyld, T. Engh, M. Tangstad, Trans. Nonferrous Met. Soc. China (English Ed.) 22, 1930 (2012)

A. Hosseini Monazzah, H. Pouraliakbar, R. Bagheri, S.M. Seyed Reihani, Compos. Part B Eng. 125, 49 (2017)

J. Park, J. Lee, I. Jo, S. Cho, S.K. Lee, S.B. Lee, H.J. Ryu, S.H. Hong, Surf. Coat. Technol. 307, 399 (2016)

X.Y. Nie, J.C. Liu, H.X. Li, Q. Du, J.S. Zhang, L.Z. Zhuang, Mater. Des. 63, 142 (2014)

S.V. Prasad, R. Asthana, Tribol. Lett. 17, 445 (2004)

R. Gecu, A. Karaaslan, Tribol. Lett. 65, 164 (2017)

S.K. Thakur, M. Gupta, Compos. Part A Appl. Sci. Manuf. 38, 1010 (2007)

Y. Milman, D. Miracle, S. Chugunova, Intermetallics 9, 839 (2001)

A.R. Rastkar, P. Parseh, N. Darvishnia, S.M.M. Hadavi, Appl. Surf. Sci. 276, 112 (2013)

S. Djanarthany, J.C. Viala, J. Bouix, Mater. Chem. Phys. 72, 301 (2001)

B. Guo, S. Ni, R. Shen, M. Song, Mater. Sci. Eng. A 639, 269 (2015)

G. Wu, Y. Liu, Z. Xiu, L. Jiang, W. Yang, Rare Met. 29, 98 (2010)

H. Kwon, J. Mondal, K. AloGab, V. Sammelselg, M. Takamichi, A. Kawaski, M. Leparoux, J. Alloys Compd. 698, 807 (2017)

S.J.S. Chelladurai, R. Arthanari, K. Krishnamoorthy, K.S. Selvaraj, P. Govindan, Trans. Indian Inst. Met. 71, 1 (2018)

B.C. Kandpal, J. Kumar, H. Singh, Mater. Today Proc. 4, 2783 (2017)

G.M. Karthik, G.D.J. Ram, R.S. Kottada, Mater. Sci. Eng. A 653, 71 (2016)

S.F. Hassan, M. Gupta, Mater. Res. Bull. 37, 377 (2002)

J.E. Allison, G.S. Cole, JOM 45, 19 (1993)

A. Loukus, J. Loukus, Int. J. Met. 5, 57 (2011)

G.A. Gegel, D.J. Weiss, Int. J. Met. 1, 57 (2007)

H. Nakae, Y. Hiramoto, Int. J. Met. 5, 23 (2011)

J.C. Schuster, M. Palm, J. Phase Equilib. Diffus. 27, 255 (2006)

J.D. Lemm, A.R. Warmuth, S.R. Pearson, P.H. Shipway, Tribol. Int. 81, 258 (2014)

J. Li, Y. Lu, H. Zhang, L. Xin, Tribol. Int. 81, 215 (2015)

L. Tang, C. Gao, J. Huang, H. Zhang, W. Chang, Tribol. Int. 66, 165 (2013)

R. Baron, J. Wert, D. Gerard, F. Wawner, J. Mater. Sci. 32, 6435 (1997)

F. Delannay, L. Froyen, A. Deruyttere, J. Mater. Sci. 22, 1 (1987)

F.H. Stott, Tribol. Int. 35, 489 (2002)

N.P. Suh, Wear 25, 111 (1973)

S. Sawla, S. Das, Wear 257, 555 (2004)

Acknowledgement

This research was supported by Yildiz Technical University Scientific Research Projects Coordination Department with the project number of FDK-2017-3241.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gecu, R., Karaaslan, A. A Comparative Study on Titanium-Reinforced Aluminium Matrix Composites Produced by Melt Infiltration Casting and Squeeze Infiltration. Inter Metalcast 13, 311–319 (2019). https://doi.org/10.1007/s40962-018-0253-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-018-0253-0