Abstract

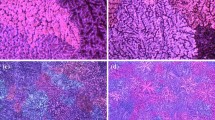

The effect of cooling rate on the grain refinement of Mg–3Nd alloys refined by Al was investigated in this work. The experimental results show that the grain size of Mg–Nd alloys can be refined by increasing the cooling rate and the Al addition. When the content of Al is more than 2%, Al2Nd particles can be observed inside the grains, which can be act as an effective nucleating site. The orientation relationship between Al2Nd particles and α-Mg matrix is determined as \( [101]_{{{\text{Al}}_{2} {\text{Nd}}}} \parallel [\bar{1}100]_{\text{Mg}} \), \( (\bar{2}22)_{{{\text{Al}}_{2} {\text{Nd}}}} \parallel (0002)_{\text{Mg}} \) and \( [\bar{1}11]_{{{\text{Al}}_{2} {\text{Nd}}}} \parallel [0001]_{\text{Mg}} \), \( (02\bar{2})_{{{\text{Al}}_{2} {\text{Nd}}}} \parallel (01\bar{1}0)_{\text{Mg}} \) by TEM analysis. The refining effect is affected by the size and the number density of Al2Nd particle. The minimum nucleating size of observed Al2Nd particle in Mg–3Nd–2Al and Mg–3Nd–3Al alloys decreases with increasing the cooling rate, which are 1.5 and 1 μm, when the cooling rate is 1.2 and 3.5 °C/s, respectively. The number density of Al2Nd particle in Mg–3Nd–2Al alloy increases with increasing the cooling rate from 0.3 to 1.2 °C/s and decreases with further increasing the cooling rate to 3.5 °C/s. And the number density of Al2Nd particle in Mg–3Nd–3Al alloy increases with increasing the cooling rate.

Similar content being viewed by others

References

S. Saha, C. Ravindran, Grain refinement of AZ91E and Mg–9 wt% Al binary alloys using zinc oxide. Int. J. Metalcast. 9(1), 33–42 (2015)

X.J. Wang, D.K. Xu, R.Z. Wu, X.B. Chen, Q.M. Peng, L. Jin, Y.C. Xin, Z.Q. Zhang, Y. Liu, X.H. Chen, G. Chen, K.K. Deng, H.Y. Wang, What is going on in magnesium alloys? J. Mater. Sci. Technol. 34, 245–247 (2018)

Q. Wen, K.K. Deng, J.Y. Shi, B.P. Zhang, W. Liang, Effect of Ca addition on the microstructure and tensile properties of Mg–4.0Zn–2.0Gd alloys. Mater. Sci. Eng. A 609(27), 1–6 (2014)

M.A. Easton, D.H. Stjohn, An analysis of the relationship between grain size, solute content, and the potency and number density of nucleant particles. Metall. Mater. Trans. A 36(7), 1911–1920 (2005)

Y. Ali, D. Qiu, B. Jiang, F.S. Pan, M.X. Zhang, Current research progress in grain refinement of cast magnesium alloys: a review article. J. Alloys Compd. 619, 639–651 (2015)

D. Qiu, M.X. Zhang, Effect of active heterogeneous nucleation particles on the grain refining efficiency in an Mg–10 wt% Y cast alloy. J. Alloy. Compd. 488(1), 260–264 (2009)

F. Wang, Z.L. Liu, D. Qiu, J.A. Taylor, M.A. Easton, M.X. Zhang, Revisiting the role of peritectics in grain refinement of Al alloys. Acta Mater. 61(1), 360–370 (2013)

G.K. Sigworth, T.A. Kuhn, Grain refinement of aluminum casting alloys. Int. J. Metalcast. 1(1), 31–40 (2007)

G.Q. Li, J.H. Zhang, R.Z. Wu, Y. Feng, S.J. Liu, X.J. Wang, Y.F. Jiao, Q. Yang, J. Meng, Development of high mechanical properties and moderate thermal conductivity cast Mg alloy with multiple RE via heat treatment. J. Mater. Sci. Technol. (2017). https://doi.org/10.1016/j.jmst.2017.12.011

X.H. Chen, Y.X. Geng, F.S. Pan, Microstructure, mechanical properties and electromagnetic shielding effectiveness of Mg–Y–Zr–Nd alloy. Rare Metal Mater. Eng. 45(1), 13–17 (2016)

D. Qiu, M.X. Zhang, The nucleation crystallography and wettability of Mg grains on active Al2Y inoculants in an Mg–10 wt% Y alloy. J. Alloys Compd. 586(5), 39–44 (2014)

D. Qiu, M.X. Zhang, P.M. Kelly, Crystallography of heterogeneous nucleation of Mg grains on Al2Y nucleation particles in an Mg–10 wt% Y alloy. Scr. Mater. 61(3), 312–315 (2009)

P. Villars, L.D. Calvert, Pearson’s Handbook of Crystallographic Data for Intermetallic Phases (ASM international, Materials Park, 1991), p. 1032

J.C. Dai, M.A. Easton, S.M. Zhu, G.H. Wu, W.J. Ding, Grain refinement of Mg–10Gd alloy by Al additions. J. Mater. Res. 27(21), 2790–2797 (2012)

C.L. Wang, J.C. Dai, W.C. Liu, L. Zhang, G.H. Wu, Effect of Al additions on grain refinement and mechanical properties of Mg–Sm alloys. J. Alloys Compd. 620, 172–179 (2015)

Z.T. Jiang, B. Jiang, Y. Zeng, J.H. Dai, F.S. Pan, Role of Al modification on the microstructure and mechanical properties of as-cast Mg–6Ce alloy. Mater. Sci. Eng. A 645(5), 57–64 (2015)

G. Atiya, M. Bamberger, A. Katsman, Microstructure and phase composition in a die cast Mg–Nd alloy. Int. J. Mater. Res. 103(10), 1277–1280 (2013)

L. Wen, Z. Ji, X. Li, M. Xin, Effect of heat treatment on microstructure and mechanical properties of ZM6 alloy prepared by solid recycling process. J. Mater. Eng. Perform. 19(1), 107–111 (2010)

J. Bai, Y.S. Sun, F. Xue, J. Qiang, Microstructures and creep properties of M–4Al–(1–4)La alloys produced by different casting techniques. Mater. Sci. Eng. A 552(9), 472–480 (2012)

F. Yavari, S.G. Shabestari, Effect of cooling rate and Al content on solidification characteristics of AZ magnesium alloys using cooling curve thermal analysis. J. Therm. Anal. Calorim. 129, 1–8 (2017)

J.C. Dai, M.A. Easton, M.X. Zhang, D. Qiu, X.Y. Xiong, W.C. Liu, G.H. Wu, Effects of cooling rate and solute content on the grain refinement of Mg–Gd–Y alloys by aluminum. Mater. Trans. A 45(10), 4665–4678 (2014)

Y.F. Jiao, J.H. Zhang, L.L. He, M.L. Zhang, F.C. Jiang, W. Wang, L.M. Han, L.J. Xu, R.Z. Wu, Al–RE intermetallic phase stability and effects on corrosion behavior in cold-chamber HPDC AE44 alloy. Adv. Eng. Mater. 18(1), 148–155 (2016)

H.W. Chang, D. Qiu, J.A. Taylor, M.A. Easton, M.X. Zhang, The role of Al2Y in grain refinement in Mg–Al–Y alloy system. J. Magn. Alloys 1(2), 115–121 (2013)

Y.F. Wu, W.B. Du, Y.N. Zhang, T.Y. Zou, Microstructure and creep property of as-cast Mg–6Al–xNd (x = 2,4,6) Alloys. Adv. Mater. Res. 146–147, 1702–1707 (2011)

D.H. Stjohn, P. Cao, M. Qian, M.A. Easton, A new analytical approach to reveal the mechanisms of grain refinement. Adv. Eng. Mater. 9(9), 739–746 (2007)

S.G. Shabestari, M. Malekan, Assessment of the effect of grain refinement on the solidification characteristics of 319 aluminum alloy using thermal analysis. J. Alloys Compd. 492(1–2), 134–142 (2010)

D.M. Stefanescu, Thermal analysis—theory and applications in metalcasting. Int. J. Metalcast. 9(1), 7–22 (2015)

M.A. Easton, D.H. Stjohn, Improved prediction of the grain size of aluminum alloys that includes the effect of cooling rate. Mater. Sci. Eng. A 486(1), 8–13 (2008)

A.L. Greer, A.M. Bunn, A. Tronche, D.J. Bristow, Modelling of inoculation of metallic melts: application to grain refinement of aluminium by Al–Ti–B. Acta Mater. 48(11), 2823–2835 (2000)

T.E. Quested, A.L. Greer, The effect of the size distribution of inoculant particles on as-cast grain size in aluminium alloys. Acta Mater. 52(13), 3859–3868 (2004)

Y. Ali, G. You, F. Pan, M.X. Zhang, Grain coarsening of cast magnesium alloys at high cooling rate: a new observation. Metall. Mater. Trans. A 48(1), 474–481 (2016)

Acknowledgements

The authors gratefully acknowledge the financial support from the Heilongjiang Province Natural Science Foundation (No. ZD2016011) and Harbin Science and Technology Innovation Talent Funding Project (No. 2016RAQXJ014).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, L., Feng, Y., Guo, E. et al. Effect of Cooling Rate on the Grain Refinement of Mg–3Nd Alloys by Aluminum. Inter Metalcast 12, 906–918 (2018). https://doi.org/10.1007/s40962-018-0224-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-018-0224-5