Abstract

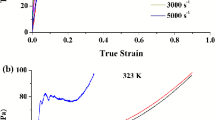

This paper concerns an experimental investigation of Polycarbonate and Poly (methyl methacrylate) compressive behavior from low to high strain rates. Experiments were conducted from 0.001/s to ≈ 5000/s for PC and from 0.001/s to ≈ 2000/s for PMMA. The true strain–stress behavior is established and analyzed at various stain rates. Both PC and PMMA mechanical behavior appears as known, to be strain rate and temperature dependent. The DSGZ model is selected for modelling the strain–stress curves while the yield stress is reproduced using the cooperative model and a modified Eyring equation based on Eyring first process theory. All the three models predictions are in agreement with experiments performed on PC and PMMA.

Similar content being viewed by others

References

Siviour CR, Jordan JL (2016) High strain rate mechanics of polymers: a review. J Dyn Behav Mater 2(1):15–32. https://doi.org/10.1007/s40870-016-0052-8

Siviour CR, Walley SM, Proud WG, Field JE (2005) The high strain rate compressive behaviour of polycarbonate and polyvinylidene difluoride. Polymer 46(26):12546–12555. https://doi.org/10.1016/j.polymer.2005.10.109

Williamson DM, Siviour CR, Proud WG, Palmer SJP, Govier R, Ellis K, Blackwell P, Leppard C (2008) Temperature–time response of a polymer bonded explosive in compression (EDC37). J Phys D 41(8):085404

Walley SMXD, Field JE (1995) Mechanical properties of three transparent polymers in compression at a very high rate of strain. In: Williams JG, Pavan A (eds) Impact and dynamic fracture of polymers and composites. Mechanical Engineering Publications edn., London, pp 289–303

Porter D (1995) Group interaction modelling of polymer properties, 1st edn. Marcel Dekker, New York

Dodd LR (1993) Computational modeling of polymers (volume 25 in the plastics engineering series)., Bicerano Jozef (ed), Dekker, New York, 1992, 648 pp. (indexed). price: $175.00. J Polym Sci Part A 31(9):2413. https://doi.org/10.1002/pola.1993.080310928

Bicerano J (2002) Prediction of polymer properties. CRC Press, Boca Rotan

Blumenthal WR, Cady CM, Lopez MF III, Idar GTG DJ (2002) Influence of temperature and strain rate on the compressive behavior of PMMA and polycarbonate polymers. AIP Conf Proc 620(1):665–668. https://doi.org/10.1063/1.1483626

Li Z, Lambros J (2001) Strain rate effects on the thermomechanical behavior of polymers. Int J Solids Struct 38(20):3549–3562. https://doi.org/10.1016/S0020-7683(00)00223-7

Walley SM, Pope JEF,PH, Safford NA (1989) A study of the rapid deformation behaviour of a range of polymers. Philos Trans R Soc Lond Ser A 328(1597):1–33. https://doi.org/10.1098/rsta.1989.0020

Walley SM FJE (1994) Strain rate sensitivity of polymers in compression from low to high rates. DYMAT J (1):211–227

Walley SM, Field JE, Pope PH, Safford N (1991) The rapid deformation behaviour of various polymers. J Phys III 1:1889–1925

Anand L, Gurtin ME (2003) A theory of amorphous solids undergoing large deformations, with application to polymeric glasses. Int J Solids Struct 40(6):1465–1487. https://doi.org/10.1016/S0020-7683(02)00651-0

Voyiadjis GZ, Samadi-Dooki A (2016) Constitutive modeling of large inelastic deformation of amorphous polymers: Free volume and shear transformation zone dynamics. J Appl Phys 119(22):225104. https://doi.org/10.1063/1.4953355

Samadi-Dooki A, Malekmotiei L, Voyiadjis GZ (2016) Characterizing shear transformation zones in polycarbonate using nanoindentation. Polymer 82:238–245. https://doi.org/10.1016/j.polymer.2015.11.049

Malekmotiei L, Samadi-Dooki A, Voyiadjis GZ (2015) Nanoindentation study of yielding and plasticity of poly(methyl methacrylate). Macromolecules 48(15):5348–5357. https://doi.org/10.1021/acs.macromol.5b01064

Boyce MC, Parks DM, Argon AS (1988) Large inelastic deformation of glassy polymers. Part I: rate dependent constitutive model. Mech Mater 7(1):15–33. https://doi.org/10.1016/0167-6636(88)90003-8

Duan Y, Saigal A, Greif R, Zimmerman MA (2001) A uniform phenomenological constitutive model for glassy and semicrystalline polymers. Polym Eng Sci 41(8):1322–1328. https://doi.org/10.1002/pen.10832

Dar UA, Zhang W (2015) Polymer based aerospace structures under high velocity impact applications; experimental, constitutive and finite element analysis. J Mech Sci Technol 29(10):4259–4265. https://doi.org/10.1007/s12206-015-0922-3

Mulliken AD, Boyce MC (2006) Mechanics of the rate-dependent elastic–plastic deformation of glassy polymers from low to high strain rates. Int J Solids Struct 43(5):1331–1356. https://doi.org/10.1016/j.ijsolstr.2005.04.016

Nasraoui M, Forquin P, Siad L, Rusinek A (2012) Influence of strain rate, temperature and adiabatic heating on the mechanical behaviour of poly-methyl-methacrylate: experimental and modelling analyses. Mater Des 37:500–509. https://doi.org/10.1016/j.matdes.2011.11.032

G’sell C, Jonas JJ (1979) Determination of the plastic behaviour of solid polymers at constant true strain rate. J Mater Sci 14(3):583–591. https://doi.org/10.1007/bf00772717

Bauwens-Crowet C, Bauwens JC, Homès G (1969) Tensile yield-stress behavior of glassy polymers. J Polym Sci A 7(4):735–742. https://doi.org/10.1002/pol.1969.160070411

Bauwens JC, Bauwens-Crowet C, Homès G (1969) Tensile yield-stress behavior of poly(vinyl chloride) and polycarbonate in the glass transition region. J Polym Sci A-2 7(10):1745–1754. https://doi.org/10.1002/pol.1969.160071010

Bauwens-Crowet C, Bauwens J-C, Homès G (1972) The temperature dependence of yield of polycarbonate in uniaxial compression and tensile tests. J Mater Sci 7(2):176–183. https://doi.org/10.1007/bf02403504

Bauwens JC (1972) Relation between the compression yield stress and the mechanical loss peak of bisphenol-A-polycarbonate in the β transition range. J Mater Sci 7(5):577–584. https://doi.org/10.1007/bf00761956

Bauwens-Crowet C (1973) The compression yield behaviour of polymethyl methacrylate over a wide range of temperatures and strain-rates. J Mater Sci 8(7):968–979. https://doi.org/10.1007/bf00756628

Eyring H (1936) Viscosity, plasticity, and diffusion as examples of absolute reaction rates. J Chem Phys 4(4):283–291. https://doi.org/10.1063/1.1749836

Richeton J, Ahzi S, Daridon L, Rémond Y (2005) A formulation of the cooperative model for the yield stress of amorphous polymers for a wide range of strain rates and temperatures. Polymer 46(16):6035–6043. https://doi.org/10.1016/j.polymer.2005.05.079

Richeton J, Ahzi S, Vecchio KS, Jiang FC, Adharapurapu RR (2006) Influence of temperature and strain rate on the mechanical behavior of three amorphous polymers: characterization and modeling of the compressive yield stress. Int J Solids Struct 43(7):2318–2335. https://doi.org/10.1016/j.ijsolstr.2005.06.040

Richeton J, Ahzi S, Daridon L (2007) Thermodynamic investigation of yield-stress models for amorphous polymers. Phil Mag 87(24):3629–3643. https://doi.org/10.1080/14786430701381162

El-Qoubaa Z, Othman R (2015) Characterization and modeling of the strain rate sensitivity of polyetheretherketone’s compressive yield stress. Mater Des (1980–2015) 66:336–345. https://doi.org/10.1016/j.matdes.2014.10.080

El-Qoubaa Z, Othman R (2015) Tensile behavior of polyetheretherketone over a wide range of strain rates. Int J Polym Sci 2015:9. https://doi.org/10.1155/2015/275937

El-Qoubaa Z, Othman R (2016) Strain rate sensitivity of polyetheretherketone’s compressive yield stress at low and high temperatures. Mech Mater 95:15–27. https://doi.org/10.1016/j.mechmat.2015.12.008

Davies RM (1948) A critical study of the Hopkinson pressure bar. Philos Trans R Soc Lond Ser A 240(821):375–457. https://doi.org/10.1098/rsta.1948.0001

Kolsky H (1949) An investigation of the mechanical properties of materials at very high rates of loading. Proc Phys Soc Sect B 62(11):676

Lindholm US (1964) Some experiments with the split hopkinson pressure bar∗. J Mech Phys Solids 12(5):317–335. https://doi.org/10.1016/0022-5096(64)90028-6

Arruda EM, Boyce MC, Jayachandran R (1995) Effects of strain rate, temperature and thermomechanical coupling on the finite strain deformation of glassy polymers. Mech Mater 19(2):193–212. https://doi.org/10.1016/0167-6636(94)00034-E

Rittel D (1999) On the conversion of plastic work to heat during high strain rate deformation of glassy polymers. Mech Mater 31(2):131–139. https://doi.org/10.1016/S0167-6636(98)00063-5

Kendall MJ, Siviour CR (2014) Experimentally simulating high-rate behaviour: rate and temperature effects in polycarbonate and PMMA. Philos Trans Ser A 372(2015):20130202. https://doi.org/10.1098/rsta.2013.0202

Rietsch F, Bouette B (1990) The compression yield behaviour of polycarbonate over a wide range of strain rates and temperatures. Eur Polym J 26(10):1071–1075. https://doi.org/10.1016/0014-3057(90)90005-O

Rittel D, Dorogoy A (2008) A methodology to assess the rate and pressure sensitivity of polymers over a wide range of strain rates. J Mech Phys Solids 56(11):3191–3205. https://doi.org/10.1016/j.jmps.2008.08.001

Johnson GR, Cook WH (1983) A constitutive model and data for metals subjected to large strains, high strain rates and high temperatures. In: Proceedings 7th international symposium on ballistics. The Hague, 19–21 April 1983, pp 541–547

Brostow W, Corneliussen RD (1986) Failure of plastics. Hanser Publishers, Munich

Brooks JW (1996) Processing wrought nickel and titanium superalloys. Thermo-mechanical processing: theory, modelling and practice. In: A conference organized in celebration of the 75th Anniversary of the Swedish Society for Materials Technology

Fotheringham DG, Cherry BW (1978) The role of recovery forces in the deformation of linear polyethylene. J Mater Sci 13(5):951–964. https://doi.org/10.1007/bf00544690

Omar MF, Akil HM, Ahmad ZA (2011) Measurement and prediction of compressive properties of polymers at high strain rate loading. Mater Des 32(8):4207–4215. https://doi.org/10.1016/j.matdes.2011.04.037

Omar MF, Akil HM, Ahmad ZA (2013) Particle size—dependent on the static and dynamic compression properties of polypropylene/silica composites. Mater Des 45:539–547. https://doi.org/10.1016/j.matdes.2012.09.026

Lefebvre JM, Escaig B (1985) Plastic deformation of glassy amorphous polymers: influence of strain rate. J Mater Sci 20(2):438–448. https://doi.org/10.1007/bf01026512

Chen LP, Yee AF, Moskala EJ (1999) The molecular basis for the relationship between the secondary relaxation and mechanical properties of a series of polyester copolymer glasses. Macromolecules 32(18):5944–5955. https://doi.org/10.1021/ma981363a

Rana D, Sauvant V, Halary JL (2002) Molecular analysis of yielding in pure and antiplasticized epoxy-amine thermosets. J Mater Sci 37(24):5267–5274. https://doi.org/10.1023/a:1021012721619

Xiao C, Jho JY, Yee AF (1994) Correlation between the shear yielding behavior and secondary relaxations of bisphenol a polycarbonate and related copolymers. Macromolecules 27(10):2761–2768. https://doi.org/10.1021/ma00088a017

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

El-Qoubaa, Z., Colard, L., Matadi Boumbimba, R. et al. Experimental Study and Modelling of Poly (Methyl Methacrylate) and Polycarbonate Compressive Behavior from Low to High Strain Rates. J. dynamic behavior mater. 4, 179–189 (2018). https://doi.org/10.1007/s40870-018-0147-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40870-018-0147-5