Abstract

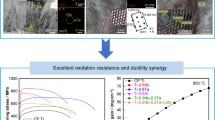

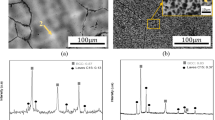

Refractory high-entropy alloys (HEAs) exhibit remarkable mechanical properties desired for high-temperature applications. However, their oxidation resistance at high temperatures received less attention. Recent work indicates that MoTaTiCrAl alloy exhibits excellent oxidation resistance, but the effects of Al and Cr remain unclear. In this work, we demonstrate that the addition of Al is unnecessary for preventing oxidation of the MoTaTiCrAl alloy and the removal of Al leads to a more oxidation resistant MoTaTiCr medium entropy alloy. Structural and chemical analyses indicate that the excellent oxidation resistance of MoTaTiCr is mainly associated with the formation of continuous CrTaO4 oxide layer. The results indicate that complex oxides can be adopted as effective candidates for enhancement of oxidation resistance, in addition to typical strategy of forming Al2O3, Cr2O3 or SiO2 barrier layer.

摘要

难熔高熵合金具有高温应用所需的优异力学性能, 但其高温抗氧化性却很少受到关注. 近期的研究表明, MoTaTiCrAl合金呈现较好的抗氧化性, 但Al和Cr两种元素对提高抗氧化性的作用仍未得以阐明. 本文发现, Al元素对防止MoTaTiCrAl合金的氧化是不必要的, 去除Al元素反而能够获得更抗氧化的MoTaTiCr中熵合金. 结构表征和成分分析表明, MoTaTiCr合金的抗氧化性主要是因为合金表面能够形成连续的CrTaO4氧化层. 本文结果说明, 除了采用Al2O3, Cr2O3 or SiO2等典型氧化物作为保护层, 在合金表面生成复杂氧化物也能有效提升难熔高熵合金的抗氧化性能.

Similar content being viewed by others

References

Yamamoto Y, Brady MP, Lu ZP, et al. Creep-resistant, Al2O3-forming austenitic stainless steels. Science, 2007, 316: 433–436

Huntz AM, Bague V, Beauplé G, et al. Effect of silicon on the oxidation resistance of 9% Cr steels. Appl Surf Sci, 2003, 207: 255–275

Liu Z, Gao W, Dahm K, et al. The effect of coating grain size on the selective oxidation behaviour of Ni-Cr-Al alloy. Scripta Mater, 1997, 37: 1551–1558

Miracle DB, Senkov ON. A critical review of high entropy alloys and related concepts. Acta Mater, 2017, 122: 448–511

Cantor B, Chang ITH, Knight P, et al. Microstructural development in equiatomic multicomponent alloys. Mater Sci Eng-A, 2004, 375–377: 213–218

Ye YF, Wang Q, Lu J, et al. High-entropy alloy: Challenges and prospects. Mater Today, 2016, 19: 349–362

Yeh JW, Chen SK, Lin SJ, et al. Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv Eng Mater, 2004, 6: 299–303

Zhang Y, Zuo TT, Tang Z, et al. Microstructures and properties of high-entropy alloys. Prog Mater Sci, 2014, 61: 1–93

Gludovatz B, Hohenwarter A, Catoor D, et al. A fracture-resistant high-entropy alloy for cryogenic applications. Science, 2014, 345: 1153–1158

Coury FG, Kaufman M, Clarke AJ. Solid-solution strengthening in refractory high entropy alloys. Acta Mater, 2019, 175: 66–81

Senkov ON, Wilks GB, Miracle DB, et al. Refractory high-entropy alloys. Intermetallics, 2010, 18: 1758–1765

Senkov ON, Miracle DB, Chaput KJ, et al. Development and exploration of refractory high entropy alloys—A review. J Mater Res, 2018, 33: 3092–3128

Gorr B, Müller F, Azim M, et al. High-temperature oxidation behavior of refractory high-entropy alloys: Effect of alloy composition. Oxid Met, 2017, 88: 339–349

Lo KC, Chang YJ, Murakami H, et al. An oxidation resistant refractory high entropy alloy protected by CrTaO4-based oxide. Sci Rep, 2019, 9: 7266

Müller F, Gorr B, Christ HJ, et al. On the oxidation mechanism of refractory high entropy alloys. Corrosion Sci, 2019, 159: 108161

Senkov ON, Senkova SV, Dimiduk DM, et al. Oxidation behavior of a refractory NbCrMo0.5Ta0.5TiZr alloy. J Mater Sci, 2012, 47: 6522–6534

Senkov ON, Miller JD, Miracle DB, et al. Accelerated exploration of multi-principal element alloys with solid solution phases. Nat Commun, 2015, 6: 6529

Guo S, Hu Q, Ng C, et al. More than entropy in high-entropy alloys: Forming solid solutions or amorphous phase. Intermetallics, 2013, 41: 96–103

Zhang Y, Zhou Y, Lin J, et al. Solid-solution phase formation rules for multi-component alloys. Adv Eng Mater, 2008, 10: 534–538

Sohn S, Liu Y, Liu J, et al. Noble metal high entropy alloys. Scripta Mater, 2017, 126: 29–32

Mendiratta MG, Parthasarathy TA, Dimiduk DM. Oxidation behavior of αMo-Mo3Si-Mo5SiB2 (T2) three phase system. Intermetallics, 2002, 10: 225–232

Gulbransen EA. High-temperature oxidation of tungsten, molybdenum and carbon. Nature, 1963, 198: 82–83

Gulbransen EA, Andrew KF, Brassart FA. Oxidation of molybdenum 550°C to 1700°C. J Electrochem Soc, 1963, 110: 952–959

Xu C, Gao W. Pilling-bedworth ratio for oxidation of alloys. Mater Res Innovations, 2000, 3: 231–235

Dunn JS. The high temperature oxidation of metals. Proc R Soc Lond A, 1926, 111: 203–209

Acknowledgements

This work was supported by the National Key Research and Development Program of China (2018YFA0703600), the National Science Fund for Distinguished Young Scholars (51825104), the Key Research Program of Frontier Sciences of Chinese Academy of Sciences (QYZDY-SSW-JSC017), the Strategic Priority Research Program of Chinese Academy of Sciences (XDB30000000), the Key Basic and Applied Research Program of Guangdong Province, China (2019B030302010), and the National Natural Science Foundation of China (11790291 and 61888102).

Author information

Authors and Affiliations

Contributions

Author contributions Liu YH conceived the research. Li LC, Li MX, and Liu YH designed the experiments. Li LC performed the experiments with assistance from Liu M and Sun BY. Li LC, Liu YH, Wang C analyzed the data. Li LC and Liu YH wrote the paper with input from Wang C, Li MX, Huo JT and Wang WH. All authors contributed to the general discussion.

Corresponding author

Ethics declarations

Conflict of interest The authors declare no competing interest.

Additional information

Li-Chao Li is currently a PhD candidate in condensed matter physics under the supervision of Professor Yan-Hui Liu at the Institute of Physics, Chinese Academy of Sciences. He received his BSc degree in physics from Lanzhou University in 2015. His research focuses on the phase formation and properties of high entropy alloys.

Yan-Hui Liu received his PhD degree from the Institute of Physics, Chinese Academy of Sciences. From 2007 to 2016, he conducted research in Tohoku University (Japan) and Yale University (USA). He joined the Institute of Physics, Chinese Academy of Sciences as an associate professor in 2016, and was promoted to professor in 2018. His research focuses on the development of high-performing alloys, in particular, metallic glasses and high-entropy alloys, by combinatorial approaches.

Rights and permissions

About this article

Cite this article

Li, LC., Li, MX., Liu, M. et al. Enhanced oxidation resistance of MoTaTiCrAl high entropy alloys by removal of Al. Sci. China Mater. 64, 223–231 (2021). https://doi.org/10.1007/s40843-020-1332-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40843-020-1332-2