Abstract

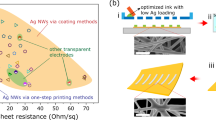

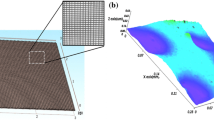

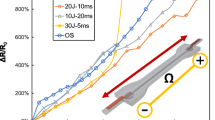

Integrating the topology design and printing method offers a promising methodology to realize large stretchability for interconnects. Herein, eco-friendly and water-based Ag nanowires (NWs) inks were formulated and used for screen-printing highly stretchable and flexible interconnects on a large area (more than 335 mm × 175 mm). The stretchability of the interconnects was realized by introducing kirigami topology structures. The topology designed models were established to simulate the influence of kirigami patterns on wire compliance and to estimate the maximum stretchability via finite element analysis (FEA). The mechanic mechanism results demonstrate that an increase of the wave numbers results in larger stretchability, and the rectangular type of wave shows better stretchability than the zigzag and sine structures. Comparatively, the electrical and mechanical properties of the interconnects were measured and analyzed, and the experimental results were consistent with FEA. The electric conductivity of the interconnects is stable at ∼10,427 S cm−1 even after 1000 cycles of 15.83 mm radius bending, 280% stretching and 200% twisting-stretching deformation, demonstrating outstanding mechanical reliability of the interconnects. The topology designed interconnects have been applied in stretchable flexible light-emitting diode, indicating their broad application prospects in next-generation stretchable electronics.

摘要

结合拓扑设计和印刷方法来实现高可拉伸性互连电极的制 备有望成为一种非常有前途的策略. 本文借助丝网印刷技术, 所配 制的银纳米线水性油墨被用于制备大面积(超过335 mm × 177 mm) 的高可拉伸柔性互连电极. 电极的可拉伸性通过引入剪纸拓扑结 构来实现, 并通过有限元法分析了所设计的系列剪纸拓扑模型对 变形顺应性的影响, 以此探究其最优拉伸性. 系统的力学机理分析 表明结构的可拉伸性随着波数的增加而增加, 与锯齿形波和正弦 形波剪纸结构相比, 矩形波结构具有最佳可拉伸性. 此外, 电极的 电学性能测试结果与有限元分析预测的结果相一致. 该方法制备 的互连电极具有 ∼10427 S cm−1 的高电导率, 并且表现出优异的力 学稳定性, 经过 1000次的弯曲循环(弯曲半径为 15.83 mm)、拉伸 循环(拉伸率为280%)和扭转-拉伸循环(扭转 180°, 拉伸率为 200%) 测试, 电导率始终保持稳定. 基于拓扑设计的互连电极被应用于可 拉伸柔性LED电路, 进一步证明其在下一代可拉伸电子产品中具有 广泛的应用前景.

Similar content being viewed by others

References

Wu W. Inorganic nanomaterials for printed electronics: A review. Nanoscale, 2017, 9: 7342–7372

Wu W. Stretchable electronics: Functional materials, fabrication strategies and applications. Sci Tech Adv Mater, 2019, 20: 187–224

Tian B, Yao W, Zeng P, et al. All-printed, low-cost, tunable sensing range strain sensors based on Ag nanodendrite conductive inks for wearable electronics. J Mater Chem C, 2019, 7: 809–818

White MS, Kaltenbrunner M, Głowacki ED, et al. Ultrathin, highly flexible and stretchable pleds. Nat Photon, 2013, 7: 811–816

Sekitani T, Nakajima H, Maeda H, et al. Stretchable active-matrix organic light-emitting diode display using printable elastic conductors. Nat Mater, 2009, 8: 494–499

Liang J, Li L, Niu X, et al. Elastomeric polymer light-emitting devices and displays. Nat Photon, 2013, 7: 817–824

Andersson P, Forchheimer R, Tehrani P, et al. Printable all-organic electrochromic active-matrix displays. Adv Funct Mater, 2007, 17: 3074–3082

Wei Y, Chen S, Lin Y, et al. Cu-Ag core-shell nanowires for electronic skin with a petal molded microstructure. J Mater Chem C, 2015, 3: 9594–9602

Vosgueritchian M, Tok JBH, Bao Z. Light-emitting electronic skin. Nat Photon, 2013, 7: 769–771

Matsuzaki R, Tabayashi K. Highly stretchable, global, and distributed local strain sensing line using GaInSn electrodes for wearable electronics. Adv Funct Mater, 2015, 25: 3806–3813

Lipomi DJ, Vosgueritchian M, Tee BCK, et al. Skin-like pressure and strain sensors based on transparent elastic films of carbon nanotubes. Nat Nanotech, 2011, 6: 788–792

Gu H, Zhang H, Ma C, et al. Smart strain sensing organic-inorganic hybrid hydrogels with nano barium ferrite as the cross-linker. J Mater Chem C, 2019, 7: 2353–2360

Wei H, Wang H, Xia Y, et al. An overview of lead-free piezoelectric materials and devices. J Mater Chem C, 2018, 6: 12446–12467

Jiang D, Wang Y, Li B, et al. Flexible sandwich structural strain sensor based on silver nanowires decorated with self-healing substrate. Macromol Mater Eng, 2019, 143: 1900074

Jiang D, Murugadoss V, Wang Y, et al. Electromagnetic interference shielding polymers and nanocomposites—a review. Polym Rev, 2019, 59: 280–337

Wang C, Murugadoss V, Kong J, et al. Overview of carbon nanostructures and nanocomposites for electromagnetic wave shielding. Carbon, 2018, 140: 696–733

Wu N, Xu D, Wang Z, et al. Achieving superior electromagnetic wave absorbers through the novel metal-organic frameworks derived magnetic porous carbon nanorods. Carbon, 2019, 145: 433–444

Liang T, Qi L, Ma Z, et al. Experimental study on thermal expansion coefficient of composite multi-layered flaky gun propellants. Compos Part B-Eng, 2019, 166: 428–435

Rogers JA, Someya T, Huang Y. Materials and mechanics for stretchable electronics. Science, 2010, 327: 1603–1607

Zhang S, Li Y, Tian Q, et al. Highly conductive, flexible and stretchable conductors based on fractal silver nanostructures. J Mater Chem C, 2018, 6: 3999–4006

Guan YS, Zhang Z, Tang Y, et al. Kirigami-inspired nanoconfined polymer conducting nanosheets with 2000% stretchability. Adv Mater, 2000, 30: 1706390

Prasad O, Jha P, Pillai S, et al. Interconnects on elastomers: Optimizing for stretchability, speed and layout area. Flex Print Electron, 2017, 2: 045007

Yu C, Masarapu C, Rong J, et al. Stretchable supercapacitors based on buckled single-walled carbon-nanotube macrofilms. Adv Mater, 2009, 21: 4793–4797

Lacour SP, Wagner S, Huang Z, et al. Stretchable gold conductors on elastomeric substrates. Appl Phys Lett, 2003, 82: 2404–2406

Lacour SP, Jones J, Wagner S, et al. Stretchable interconnects for elastic electronic surfaces. Proc IEEE, 2005, 93: 1459–1467

Catenacci MJ, Reyes C, Cruz MA, et al. Stretchable conductive composites from Cu-Ag nanowire felt. ACS Nano, 2018, 12: 3689–3698

Fan JA, Yeo WH, Su Y, et al. Fractal design concepts for stretchable electronics. Nat Commun, 2014, 5: 3266

Su Y, Wang S, Huang YA, et al. Elasticity of fractal inspired interconnects. Small, 2015, 11: 367–373

Dang W, Vinciguerra V, Lorenzelli L, et al. Printable stretchable interconnects. Flex Print Electron, 2017, 2: 013003

Jiang C, Zhong Z, Liu B, et al. Coffee-ring-free quantum dot thin film using inkjet printing from a mixed-solvent system on modified ZnO transport layer for light-emitting devices. ACS Appl Mater Interfaces, 2016, 8: 26162–26168

Choi MK, Yang J, Kang K, et al. Wearable red-green-blue quantum dot light-emitting diode array using high-resolution intaglio transfer printing. Nat Commun, 2015, 6: 7149

Fukuda K, Takeda Y, Yoshimura Y, et al. Fully-printed high-performance organic thin-film transistors and circuitry on one-micron-thick polymer films. Nat Commun, 2014, 5: 4147

Liang J, Tong K, Pei Q. A water-based silver-nanowire screen-print ink for the fabrication of stretchable conductors and wearable thin-film transistors. Adv Mater, 2016, 28: 5986–5996

Cao R, Wang J, Zhao S, et al. Self-powered nanofiber-based screen-print triboelectric sensors for respiratory monitoring. Nano Res, 2018, 11: 3771–3779

Huang L, Huang Y, Liang J, et al. Graphene-based conducting inks for direct inkjet printing of flexible conductive patterns and their applications in electric circuits and chemical sensors. Nano Res, 2011, 4: 675–684

Lu Q, Liu L, Yang S, et al. Facile synthesis of amorphous FeOOH/MnO2 composites as screen-printed electrode materials for all-printed solid-state flexible supercapacitors. J Power Sources, 2017, 361: 31–38

Liu L, Lu Q, Yang S, et al. All-printed solid-state micro-supercapacitors derived from self-template synthesis of Ag@PPy nanocomposites. Adv Mater Technol, 2018, 3: 1700206

Krebs FC, Jørgensen M, Norrman K, et al. A complete process for production of flexible large area polymer solar cells entirely using screen printing—first public demonstration. Sol Energy Mater Sol Cells, 2009, 93: 422–441

Singh M, Haverinen HM, Dhagat P, et al. Inkjet printing-process and its applications. Adv Mater, 2010, 22: 673–685

Yim C, Kockerbeck ZA, Jo SB, et al. Hybrid copper-silver-graphene nanoplatelet conductive inks on PDMS for oxidation resistance under intensive pulsed light. ACS Appl Mater Interfaces, 2017, 9: 37160–37165

Cui Z, Han Y, Huang Q, et al. Electrohydrodynamic printing of silver nanowires for flexible and stretchable electronics. Nanoscale, 2018, 10: 6806–6811

Yao W, Tian Q, Liu J, et al. Large-scale synthesis and screen printing of upconversion hexagonal-phase NaYF4:Yb3+, Tm3+/Er3+/Eu3+ plates for security applications. J Mater Chem C, 2016, 4: 6327–6335

Kamyshny A, Magdassi S. Conductive nanomaterials for printed electronics. Small, 2014, 10: 3515–3535

Matsuhisa N, Kaltenbrunner M, Yokota T, et al. Printable elastic conductors with a high conductivity for electronic textile applications. Nat Commun, 2015, 6: 7461

Bandodkar AJ, Nuñez-Flores R, Jia W, et al. All-printed stretchable electrochemical devices. Adv Mater, 2015, 27: 3060–3065

Xue Q, Yao W, Liu J, et al. Facile synthesis of silver nanowires with different aspect ratios and used as high-performance flexible transparent electrodes. Nanoscale Res Lett, 2017, 12: 480

Xu F, Zhu Y. Highly conductive and stretchable silver nanowire conductors. Adv Mater, 2012, 24: 5117–5122

Chun KY, Oh Y, Rho J, et al. Highly conductive, printable and stretchable composite films of carbon nanotubes and silver. Nat Nanotech, 2010, 5: 853–857

Sekitani T, Noguchi Y, Hata K, et al. A rubberlike stretchable active matrix using elastic conductors. Science, 2008, 321: 1468–1472

Acknowledgements

This work was supported by the National Nature Science Foundation of China (51471121), the Basic Research Plan Program of Shenzhen City (JCYJ20170303170426117), the Natural Science Foundation of Jiangsu Province (BK20160383), the Fundamental Research Funds for the Central Universities (2042018kf203) and Wuhan University.

Author information

Authors and Affiliations

Contributions

Author contributions Li X, Ruan X, Xia R and Wu W conceived the project and wrote the paper. Li X and Wu W designed the experiments. Li X performed the fabrication of the interconnects and measured the electrical and mechanical properties. Ruan X conducted the theoretical simulations via finite element analysis. Yao W, Liu L, Tian B, Wang H and Feng Y provided inputs into the design of the experiments and the preparation of the manuscript.

Corresponding authors

Additional information

Conflict of interest The authors declare that they have no competing interests.

Xuan Li is currently pursuing a Master degree under the supervision of Prof. Wei Wu in the School of Printing and Packaging at Wuhan University. His current research focuses on the functional nanomaterials for printed electronics.

Xiaoli Ruan is currently pursuing a Master degree under the supervision of Prof. Re Xia in the School of Power and Mechanical Engineering at Wuhan University. Her current research focuses on the mechanical properties of the composite materials.

Re Xia received his PhD degree in 2010 from the Department of Engineering Mechanics, Tsinghua University, China. He has been an associate professor in the Department of Mechanical Engineering, School of Power and Mechanical Engineering, Wuhan University since 2011. He is currently the deputy director of the Key Laboratory of Hydraulic Machinery Transients (Wuhan University), Ministry of Education. His research interests include the mechanical properties of nanoporous materials and composite structures.

Wei Wu received his PhD degree in 2011 from the Department of Physics, Wuhan University, China. He then joined the groups of Prof. Daiwen Pang at Wuhan University (2011) and Prof. V. A. L. Roy at the City University of Hong Kong (2014) as a postdoctoral fellow. Now he is the full professor and Director of the Laboratory of Printable Functional Nanomaterials and Printed Electronics, School of Printing and Packaging, Wuhan University. He has published more than 80 papers, which have received more than 4000 citations. He received the STAM Best Paper Award in 2017 and Hong Kong Scholars Award in 2014. He is also the topical editor of Frontiers in Materials. His research interests include the synthesis and applications of functional nanomaterials, printed electronics and intelligent packaging.

Electronic supplementary material

40843_2019_9447_MOESM1_ESM.pdf

Large-area, kirigami topology structure-induced highly stretchable and flexible interconnects: Directly printing preparation and mechanic mechanism

Rights and permissions

About this article

Cite this article

Li, X., Ruan, X., Yao, W. et al. Large-area, kirigami topology structure-induced highly stretchable and flexible interconnects: Directly printing preparation and mechanic mechanism. Sci. China Mater. 62, 1412–1422 (2019). https://doi.org/10.1007/s40843-019-9447-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40843-019-9447-0