Abstract

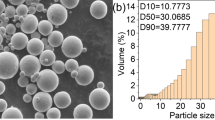

The corrosion resistance and cytocompatibility of Ti-20Zr-10Nb-4Ta (TZNT) alloy modified by surface laser treatment were investigated. The scanning electron microscopy (SEM) measurements indicated that laser treatment on TZNT alloy generated groove morphologies with the width of ∼40 μm and the depth of ∼10 μm on the surface. The water contact angles along the groove direction decreased by 51% compared with that of the untreated alloy. The laser treatment promoted the oxidation of metallic Ti, Zr and Nb and produced more stable oxides on surface. The corrosion potential increased by 50% and corrosion current density decreased by 72% compared with that of the untreated alloy in the anodic polarization test for the alloy in Hank’s solution at 37°C. This indicated the improvement of the corrosion resistance by laser treatment. The cytotoxicity testing results showed that the laser-treated TZNT alloy performed similar MC3T3-E1 cell viability compared with the untreated alloy. The cells displayed oriented growth along the groove direction due to the increased hydrophilicity. This novel material may be a new candidate in orthopedics and dentistry implantations fields.

摘要

本文系统研究了激光表面改性对Ti-20Zr-10Nb-4Ta(TZNT)合金耐腐蚀性和细胞相容性的影响. 扫描电镜观察结果表明, 激光改性能够在TZNT合金表面制造沟槽结构, 沟槽宽度大概40 μm, 沟槽深度大概10 μm. 与未处理样品相比, 改性样品表面沿沟槽方向的水接触角减小了51%. 激光处理过程使样品表面金属态的Ti、 Zr和Nb转变成了稳定的氧化态. 在37°C的Hank’s溶液中进行动电位极化测试发现, 改性样品的自腐蚀电位升高了50%, 自腐蚀电流密度下降了72%, 说明激光改性能够提高TZNT合金的耐腐蚀能力. MTT实验结果表明小鼠成骨细胞(MC3T3-E1)在改性样品和非改性样品表面具有相似的细胞活性. 从细胞形貌可以看出, 细胞出现了沿沟槽方向生长的导向性. 综上所述, 新型生物医用TZNT合金有望成为骨科和牙科植入领域的替代材料.

Article PDF

Similar content being viewed by others

References

Deligianni D. Effect of surface roughness of the titanium alloy Ti–6Al–4V on human bone marrow cell response and on protein adsorption. Biomaterials, 2001, 22: 1241–1251

Scarano A, Piattelli M, Caputi S, et al. Bacterial adhesion on commercially pure titanium and zirconium oxide disks: an in vivo human study. J Periodontol, 2004, 75: 292–296

El-Ghannam A, Starr L, Jones J. Laminin-5 coating enhances epithelial cell attachment, spreading, and hemidesmosome as-sembly on Ti-6Al-4V implant material in vitro. J Biomed Mater Res, 1998, 41: 30–40

Niinomi M, Nakai M, Hieda J. Development of new metallic alloys for biomedical applications. Acta Biomater, 2012, 8: 3888–3903

Hao YL, Li SJ, Yang R. Biomedical titanium alloys and their additive manufacturing. Rare Met, 2016, 35: 661–671

Qu WT, Sun XG, Yuan BF, et al. Tribological behaviour of biomedical Ti–Zr-based shape memory alloys. Rare Met, 2017, 36: 478–484

Jin M, Lu X, Qiao Y, et al. Fabrication and characterization of anodic oxide nanotubes on TiNb alloys. Rare Met, 2016, 35: 140–148

Oliveira NTC, Ferreira EA, Duarte LT, et al. Corrosion resistance of anodic oxides on the Ti–50Zr and Ti–13Nb–13Zr alloys. Electrochim Acta, 2006, 51: 2068–2075

Elias LM, Schneider SG, Schneider S, et al. Microstructural and mechanical characterization of biomedical Ti–Nb–Zr(–Ta) alloys. Mater Sci Eng-A, 2006, 432: 108–112

Fukuda A, Takemoto M, Saito T, et al. Bone bonding bioactivity of Ti metal and Ti–Zr–Nb–Ta alloys with Ca ions incorporated on their surfaces by simple chemical and heat treatments. Acta Biomater, 2011, 7: 1379–1386

Ozan S, Lin J, Li Y, et al. New Ti-Ta-Zr-Nb alloys with ultrahigh strength for potential orthopedic implant applications. J Mech Behav BioMed Mater, 2017, 75: 119–127

Xue P, Li Y, Li K, et al. Superelasticity, corrosion resistance and biocompatibility of the Ti–19Zr–10Nb–1Fe alloy. Mater Sci Eng-C, 2015, 50: 179–186

Xiong C, Xue P, Sun B, et al. Effect of annealing temperature on the microstructure and superelasticity of Ti-19Zr-10Nb-1Fe alloy. Mater Sci Eng-A, 2017, 688: 464–469

Xiong C, Yao L, Yuan B, et al. Strain induced martensite stabilization and shape memory effect of Ti–20Zr–10Nb–4Ta alloy. Mater Sci Eng-A, 2016, 658: 28–32

Soboyejo WO, Nemetski B, Allameh S, et al. Interactions between MC3T3-E1 cells and textured Ti6Al4V surfaces. J Biomed Mater Res, 2002, 62: 56–72

Ohtsu N, Kozuka T, Yamane M, et al. Surface chemistry and osteoblast-like cell response on a titanium surface modified by a focused Nd:YAG laser. Surf Coatings Tech, 2017, 309: 220–226

Man HC, Cui ZD, Yue TM. Corrosion properties of laser surface melted NiTi shape memory alloy. Scripta Mater, 2001, 45: 1447–1453

Wong MH, Cheng FT, Pang GKH, et al. Characterization of oxide film formed on NiTi by laser oxidation. Mater Sci Eng-A, 2007, 448: 97–103

Lawrence J, Hao L, Chew HR. On the correlation between Nd:YAG laser-induced wettability characteristics modification and osteoblast cell bioactivity on a titanium alloy. Surf Coatings Tech, 2006, 200: 5581–5589

Chen J, Ulerich JP, Abelev E, et al. An investigation of the initial attachment and orientation of osteoblast-like cells on laser grooved Ti-6Al-4V surfaces. Mater Sci Eng-C, 2009, 29: 1442–1452

Ulerich JP, Ionescu LC, Chen J, et al. Modifications of Ti-6Al-4V surfaces by direct-write laser machining of linear grooves. Proc of SPIE, 2007, 6458: 645819

Mukherjee S, Dhara S, Saha P. Enhancing the biocompatibility of Ti6Al4V implants by laser surface microtexturing: an in vitro study. Int J Adv Manuf Technol, 2015, 76: 5–15

Raimbault O, Benayoun S, Anselme K, et al. The effects of femtosecond laser-textured Ti-6Al-4V on wettability and cell response. Mater Sci Eng-C, 2016, 69: 311–320

Chan CW, Lee S, Smith G, et al. Enhancement of wear and corrosion resistance of beta titanium alloy by laser gas alloying with nitrogen. Appl Surf Sci, 2016, 367: 80–90

Saebnoori E, Shahrabi T, Sanjabi S, et al. Surface characteristics and electrochemical behaviour of sputter-deposited NiTi thin film. Philos Mag, 2015, 95: 1696–1716

Li K, Li Y, Huang X, et al. Surface microstructures and corrosion resistance of Ni-Ti-Nb shape memory thin films. Appl Surf Sci, 2017, 414: 63–67

Kumari R, Scharnweber T, Pfleging W, et al. Laser surface textured titanium alloy (Ti–6Al–4V)–Part II–Studies on bio-compatibility. Appl Surf Sci, 2015, 357: 750–758

Liang C, Wang H, Yang J, et al. Biocompatibility of the micropatterned NiTi surface produced by femtosecond laser. Appl Surf Sci, 2012, 261: 337–342

Ohtsu N, Kozuka T, Hirano M, et al. Electrolyte effects on the surface chemistry and cellular response of anodized titanium. Appl Surf Sci, 2015, 349: 911–915

Dumas V, Rattner A, Vico L, et al. Multiscale grooved titanium processed with femtosecond laser influences mesenchymal stem cell morphology, adhesion, and matrix organization. J Biomed Mater Res, 2012, 100A: 3108–3116

Acknowledgements

This work was supported by the National Natural Science Foundation of China (NSFC, 51771011) and the Fundamental Research Funds for the Central Universities (KG12002601).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Xianda Xue received his bachelor’s degree from Beihang University in 2014. Now he is pursuing his PhD degree (metallic materials) at Beihang University continuously. His research interests focus on the technique improving surface of metallic materials.

Yan Li is a professor of the School of Materials Science and Engineering at Beihang University. He received his PhD degree from Dalian University of Technology in 2001. His current research interests include shape memory materials, biomedical materials, and supercapacitors and battery materials.

Yingchun Guan is currently a professor in the School of Mechanical Engineering and Automation, Beihang University. She received her PhD degree from Nanyang Technological University (Singapore) in 2011. She had been served as Scientist in Singapore Institute of Manufacturing Technology from 2011 to 2014. Her major research interests include laser precision manufacturing and laser additive manufacturing.

Rights and permissions

About this article

Cite this article

Xue, X., Ma, C., An, H. et al. Corrosion resistance and cytocompatibility of Ti-20Zr-10Nb-4Ta alloy surface modified by a focused fiber laser. Sci. China Mater. 61, 516–524 (2018). https://doi.org/10.1007/s40843-017-9239-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40843-017-9239-3