Abstract

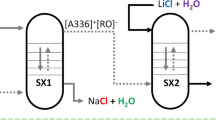

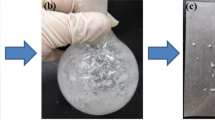

Lithium is a critical metal with a wide range of applications in energy, electronics, and chemical industry. Currently, the industrial method for Li metal extraction relies on electrolysis of molten LiCl and suffers from various safety, cost, and environmental issues. In this work, we report electrochemical extraction of Li from molten LiOH by using a liquid tin (Sn) cathode. The use of liquid Sn cathode offers various advantages, such as lowering the dissociation potential of LiOH and easy collection of the metallic Li. Electrochemical and materials characterization results reveal that a plunge of electrolysis current occurs in the electrolyser without using a porous alumina membrane, due to the formation of a Li2O passivation layer at the cathode/electrolyte interface. In the electrolyser with a porous alumina membrane, continuous electrolysis has been achieved, and the side surface of the liquid Sn is identified to be the effective interface for Li electrodeposition. In addition, we demonstrate the use of the Li–Sn product for the synthesis of acetylene (C2H2), a widely used fuel and chemical feedstock.

Graphical Abstract

Similar content being viewed by others

References

Kipouros GJ, Sadoway DR (1998) Toward new technologies for the production of lithium. JOM 50(5):24–26

Sidhar H, Martinez NY, Mishra RS, Silvanus J (2016) Friction stir welding of Al–Mg–Li 1424 alloy. Mater Des 106:146–152

Fütterer MA, Aiello G, Barbier F, Giancarli L, Poitevin Y, Sardain P, Szczepanski J, Li Puma A, Ruvutuso G, Vella G (2000) On the use of tin–lithium alloys as breeder material for blankets of fusion power plants. J Nucl Mater 283–287:1375–1379

de Castro A, Moynihan C, Stemmley S, Szott M, Andruczyk D, Ruzic DN (2020) Exploration of Sn70Li30 alloy as possible material for flowing liquid metal plasma facing components. Nucl Mater Energy 25:100829

Holroyd RJ, Mitchell JTD (1984) Liquid lithium as a coolant for Tokamak fusion reactors. Nucl Eng Des Fusion 1(1):17–38

Merwin A, Williamson MA, Willit JL, Chidambaram D (2017) Review—Metallic lithium and the reduction of actinide oxides. J Electrochem Soc 164(8):H5236–H5246

Cohen T, Bhupathy M (1989) Organoalkali compounds by radical anion induced reductive metalation of phenyl thioethers. Acc Chem Res 22(4):152–161

Jain A, Miyaoka H, Ichikawa T (2016) Destabilization of lithium hydride by the substitution of group 14 elements: a review. Int J Hydrog Energy 41(14):5969–5978

McEnaney JM, Singh AR, Schwalbe JA, Kibsgaard J, Lin JC, Cargnello M, Jaramillo TF, Nørskov JK (2017) Ammonia synthesis from N2 and H2O using a lithium cycling electrification strategy at atmospheric pressure. Energy Environ Sci 10(7):1621–1630

Yamaguchi S, Ichikawa T, Wang Y, Nakagawa Y, Isobe S, Kojima Y, Miyaoka H (2017) Nitrogen dissociation via reaction with lithium alloys. ACS Omega 2(3):1081–1088

Martin G, Rentsch L, Höck M, Bertau M (2017) Lithium market research—global supply, future demand and price development. Energy Storage Mater 6:171–179

Obrovac MN, Chevrier VL (2014) Alloy negative electrodes for Li-ion batteries. Chem Rev 114(23):11444–11502

Wang K, Jiang K, Chung B, Ouchi T, Burke PJ, Boysen DA, Bradwell DJ, Kim H, Muecke U, Sadoway DR (2014) Lithium–antimony–lead liquid metal battery for grid-level energy storage. Nature 514(7522):348–350

Peiró LT, Méndez GV, Ayres RU (2013) Lithium: sources, production, uses, and recovery outlook. JOM 65(8):986–996

Lang J, Jin Y, Liu K, Long Y, Zhang H, Qi L, Wu H, Cui Y (2020) High-purity electrolytic lithium obtained from low-purity sources using solid electrolyte. Nat Sustain 3:386–390

Zhang W-J (2011) Lithium insertion/extraction mechanism in alloy anodes for lithium-ion batteries. J Power Sources 196(3):877–885

Zhang X, Han A, Yang Y (2020) Review on the production of high-purity lithium metal. J Mater Chem A 8:22455–22466

Lantelme F, Kaplan B, Groult H, Devilliers D (1999) Mechanism for elemental carbon formation in molecular ionic liquids. J Mol Liq 83(1):255–269

Kaplan B, Groult H, Barhoun A, Lantelme F, Nakajima T, Gupta V, Komaba S, Kumagai N (2002) Synthesis and structural characterization of carbon powder by electrolytic reduction of molten Li2CO3–Na2CO3–K2CO3. J Electrochem Soc 149(5):D72

Ijije HV, Lawrence RC, Siambun NJ, Jeong SM, Jewell DA, Hu D, Chen GZ (2014) Electro-deposition and re-oxidation of carbon in carbonate-containing molten salts. Faraday Discuss 172:105–116

Yin H, Mao X, Tang D, Xiao W, Xing L, Zhu H, Wang D, Sadoway DR (2013) Capture and electrochemical conversion of CO2 to value-added carbon and oxygen by molten salt electrolysis. Energy Environ Sci 6(5):1538–1545

Zhang B, Xie H, Lu B, Chen X, Xing P, Qu J, Song Q, Yin H (2019) A green electrochemical process to recover Co and Li from spent LiCoO2-based batteries in molten salts. ACS Sustain Chem Eng 7(15):13391–13399

DeYong DH (1991) Production of lithium by direct electrolysis of lithium carbonate. US4988417

Kruesi WH, Fray DJ (1993) The electrowinning of lithium from chloride-carbonate melts. Metall Trans B 24(4):605–615

Olivetti EA, Ceder G, Gaustad GG, Fu X (2017) Lithium-ion battery supply chain considerations: analysis of potential bottlenecks in critical metals. Joule 1(2):229–243

Laude T, Kobayashi T, Sato Y (2010) Electrolysis of LiOH for hydrogen supply. Int J Hydrog Energy 35(2):585–588

Takeda O, Li M, Toma T, Sugiyama K, Hoshi M, Sato Y (2014) Electrowinning of lithium from LiOH in molten chloride. J Electrochem Soc 161(14):D820–D823

McEnaney JM, Rohr BA, Nielander AC, Singh AR, King LA, Nørskov JK, Jaramillo TF (2020) A cyclic electrochemical strategy to produce acetylene from CO2, CH4, or alternative carbon sources. Sustain Energy Fuels 4:2752–2759

Gibilaro M, Bolmont S, Massot L, Latapie L, Chamelot P (2014) On the use of liquid metals as cathode in molten fluorides. J Electroanal Chem 726:84–90

Jiao H, Wang J, Zhang L, Zhang K, Jiao S (2015) Electrochemically depositing titanium(iii) ions at liquid tin in a NaCl–KCl melt. RSC Adv 5(76):62235–62240

Guan X, Pal UB, Jiang Y, Su S (2016) Clean metals production by solid oxide membrane electrolysis process. J Sustain Metall 2(2):152–166

Han W, Li W, Li M, Yang Z, Chen L, Zhang Y, Meng Y, Li Q, Sun Y (2020) Electrochemical extraction of metallic Y using solid and liquid double cathodes. Electrochim Acta 346:136233

Lichtenstein T, Nigl TP, Smith ND, Kim H (2018) Electrochemical deposition of alkaline-earth elements (Sr and Ba) from LiCl-KCl-SrCl2-BaCl2 solution using a liquid bismuth electrode. Electrochim Acta 281:810–815

Nigl TP, Lichtenstein T, Kong Y, Kim H (2020) Electrochemical separation of alkaline-Earth elements from molten salts using liquid metal electrodes. ACS Sustain Chem Eng 8(39):14818–14824

Jiang Y, Xu J, Guan X, Pal UB, Basu SN (2013) Production of silicon by solid oxide membrane-based electrolysis process. MRS Proc 1493:231–235

Xu J, Lo B, Jiang Y, Pal U, Basu S (2014) Stability of yttria stabilized zirconia in molten oxy-fluorite flux for the production of silicon with the solid oxide membrane process. J Eur Ceram Soc 34(15):3887–3896

Lee T-H, Okabe TH, Lee J-Y, Kim YM, Kang J (2020) Molten salt electrolysis of magnesium oxide using a liquid-metal cathode for the production of magnesium metal. Metall Mater Trans B 51(6):2993–3006

Morachevskii AG (2015) Thermodynamic properties and electrochemical studies of lithium-tin alloys. Russ J Appl Chem 88(7):1087–1105

Kiat JM, Boemare G, Rieu B, Aymes D (1998) Structural evolution of LiOH: evidence of a solid–solid transformation toward Li2O close to the melting temperature. Solid State Commun 108(4):241–245

Xu Q, Schwandt C, Fray DJ (2004) Electrochemical investigation of lithium and tin reduction at a graphite cathode in molten chlorides. J Electroanal Chem 562(1):15–21

Xu Q, Schwandt C, Chen GZ, Fray DJ (2002) Electrochemical investigation of lithium intercalation into graphite from molten lithium chloride. J Electroanal Chem 530(1):16–22

Wen CJ, Huggins RA (1981) Thermodynamic study of the lithium-tin system. J Electrochem Soc 128(6):1181

Boukamp BA, Lesh GC, Huggins RA (1981) All-solid lithium electrodes with mixed-conductor matrix. J Electrochem Soc 128(4):725

Jin S, Ye Y, Niu Y, Xu Y, Jin H, Wang J, Sun Z, Cao A, Wu X, Luo Y, Ji H, Wan L-J (2020) Solid–solution-based metal alloy phase for highly reversible lithium metal anode. J Am Chem Soc 142(19):8818–8826

Genser O, Hafner J (2001) Structure and bonding in crystalline and molten Li–Sn alloys: a first-principles density-functional study. Phys Rev B 63(14):144204

Lide DR, Haynes WM (2010) CRC handbook of chemistry and physics. CRC Press, Boca Raton, FL

Jain A, Ong SP, Hautier G, Chen W, Richards WD, Dacek S, Cholia S, Gunter D, Skinner D, Ceder G, Persson KA (2013) Commentary: The Materials Project: a materials genome approach to accelerating materials innovation. APL Mater 1(1):011002

Kovrov VA, Mullabaev AR, Shishkin VY, Zaikov YP (2018) Solubility of Li2O in an LiCl–KCl melt. Russ Metall 2018:169

Stowe AC, Smyrl N (2012) Raman spectroscopy of lithium hydride corrosion: selection of appropriate excitation wavelength to minimize fluorescence. Vib Spectrosc 60:133–136

Gorelik VS, Bi D, Voinov YP, Vodchits AI, Gorshunov BP, Yurasov NI, Yurasova II (2017) Raman spectra of lithium compounds. J Phys Conf Ser 918:012035

Wan M, Kang S, Wang L, Lee H-W, Zheng GW, Cui Y, Sun Y (2020) Mechanical rolling formation of interpenetrated lithium metal/lithium tin alloy foil for ultrahigh-rate battery anode. Nat Commun 11(1):829

Ishiyama S, Baba Y, Fujii R, Nakamura M, Imahori Y (2012) Synthesis of lithium nitride for neutron production target of BNCT by in situ lithium deposition and ion implantation. Nucl Instrum Methods Phys Res Sect B 293:42–47

Montella C, Diard J-P (2017) Cyclic voltammetry corrupted by Ohmic Drop, Wolfram Demonstrations Project

Tian N, Gao Y, Li Y, Wang Z, Song X, Chen L (2016) Li2C2, a high-capacity cathode material for lithium ion batteries. Angew Chem Int Ed 55(2):644–648

Acknowledgements

This material was based upon work supported by the startup funding from ShanghaiTech University. The authors would like to thank Qinghai Yang for the technical assistance in SEM characterization. Part of the work was performed at the Analytical Instrumentation Center (No. SPST-AIC10112914) and the Center for High-resolution Electron Microscopy (CħEM, No. EM02161943) at ShanghaiTech University.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

The contributing editor for this article was Hojong Kim.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Tang, Z., Guan, X. Lithium Extraction from Molten LiOH by Using a Liquid Tin Cathode. J. Sustain. Metall. 7, 203–214 (2021). https://doi.org/10.1007/s40831-021-00339-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40831-021-00339-1