Abstract

Electronic waste (E-waste) generation is evaluated at 20–50 million tons, representing 1–3% of the general waste generated yearly worldwide. The large quantities of outdated and life-ended electrical and electronic equipment make it a fast-growing waste production all over the world. Printed circuit boards (PCBs) are the most highly valued precious components of E-waste. Apart from valuable metals, PCBs contain many dangerous and hazardous substances. The very unpredictable mix of such different important and hazardous materials combined in a small volume poses serious challenges for the recovery and recycling of these constituents. To prevent toxicity of these contaminants to humans and environment, it is inevitable to analyze the peculiarities and compositions of various materials in E-waste and determine how to manage their recycling via green ecofriendly processes. This paper will deal with the outline of E-waste problem, its diverse categories, composition, management, and various recycling processes especially the green ecofriendly ones with unique attention toward extraction of valuable metals. Unfortunately, despite the fact that many efforts to develop recycling technologies have been endeavored, these technologies are still rather exclusive and inadequate because of the intricacy of the E-waste system. Hence, the demerits of each process are debated and discussed from the viewpoint of technical advancement and environmental protection.

Similar content being viewed by others

References

Hoornweg D, Bhada-Tata P (2012) What a waste: a global review of solid waste management, vol 15. World Bank, Urban Development & Local Government Unit, Washington, DC, p 98

Hadi P, Ning C, Ouyang W, Xu M, Lin CSK, McKay G (2015) Toward environmentally-benign utilization of nonmetallic fraction of waste printed circuit boards as modifier and precursor. Waste Manag 35:236–246

Tuncuk A, Stazi V, Akcil A, Yazici E, Deveci H (2012) Aqueous metal recovery techniques from e-scrap: hydrometallurgy in recycling. Miner Eng 25:28–37

Guan J, Wang J, Min X, Wu W (2012) The products characteristics of calcium-basic compounds pyrolysis with waste printed circuit boards (PCB), the 7th international conference on waste management and technology. Proc Environ Sci 16:461–468

Veit HM, Diehl TR, Salami AP, Rodrigues JS, Bernardes AM, Tenorio JAS (2005) Utilization of magnetic and electrostatic separation in the recycling of printed circuit boards scrap. Waste Manag 25:67–74

United Nations Environment Programmed (UNEP) Report (2010) Urgent need to prepare developing countries for surge in E-wastes. http://www.unep.org/Documents.Multilingual

Rankin WJ (2011) Minerals, metals and sustainability: meeting future material needs. CSIRO Publishing, Collingwood

Marques A, Cabrera J, Malfatti C (2013) Printed circuit boards: a review on the perspective of sustainability. J Environ Manag 131:298–306

Duan H, Hou KL, Zhu X (2011) Examining the technology acceptance for dismantling of waste printed circuit boards in light of recycling and environmental concerns. J Environ Manag 92:392–399

He W, Li G, Ma X, Wang H, Huang J, Xu M, Huang C (2006) WEEE recovery strategies and the WEEE treatment status in China. J Hazard Mater 136:502–512

Cui J, Zhang L (2008) Metallurgical recovery of metals from electronic waste: a review. J Hazard Mater 158:228–256

Sohaili J, Muniyandi S, Suhaila SM (2012) A review on printed circuit boards waste recycling technologies and reuse of recovered nonmetallic materials. J Emerging Trends Eng Appl Sci 3:138–144

Bernardes AM, Bohlinger I, Milbrandt H, Rodriguez D, Wuth W (1997) Recycling of printed wire boards by melting with oxidizing/reducing top blowing process. In: TMS annual meeting, Orlando, Florida 9–13 February. The Minerals, Metals & Materials Society, Warrendale, pp 363–375

Hall WJ, Williams PT (2006) Fast pyrolysis of halogenated plastics recovered from waste computers. Energy Fuels 20:1536–1549

Jha M, Kumari A, Choubey P, Lee J, Kumar V, Jeong J (2012) Leaching of lead from solder material of waste printed circuit boards (PCBs). Hydrometallurgy 124:28–34

Pozzo R, Malicsi A, Iwasaki I (1991) Removal of lead from printed wire board scrap by an electrodissolution-delamination method. Resour Conserv Recycl 5:21–34

Xiu F, Qi Y, Zhang F (2013) Recovery of metals from waste printed circuit boards by supercritical water pretreatment combined with acid leaching process. Waste Manag 33:1251–1257

Yazici E, Deveci H (2013) Extraction of metals from waste printed circuit boards (WPCBs) in H2SO4-CuSO4-NaCl solutions. Hydrometallurgy 139:30–38

Aurubis Global (2015) Metal recycling. https://www.aurubis.com/en/en/corp/products/recycling/metal-recycling. Accessed Feb 2015

Aurubis Global (2015) Recycling technology. https://www.aurubis.com/en/en/. Accessed Feb 2018

Khaliq A, Rhamdhami MA, Brooks G, Masood S (2014) Metal extraction process for electronic waste and existing industrial routes: a review and Australian perspective. Resources 3:152–179

Bryan CG, Watkin E, McCredden TJ et al (2015) The use of pyrite as a source of lixiviant in the bioleaching of electronic waste. Hydrometallurgy 152:33–43

Chancerel P, Meskers CE, Hagelüken C, Potter VS (2009) Assessment of precious metal flows during preprocessing of waste electrical and electronic equipment. J Ind Ecol 13(5):791–810

Dhawan N, Kumar M, Kumar V, Wadhwa M (2008) Recovery of metals from electronic scrap by hydrometallurgical route. In: Mishra B, Ludwig C, Das SK (eds) Global symposium on recycling, waste treatment and clean technology (REWAS 2008). The Minerals, Metals & Materials Society, Warrendale, PA, pp 693–698

Zeng XL, Zheng LX, Xie HH et al (2012) Current status and future perspective of waste printed circuit boards recycling. Procedia Environ Sci 16:590–597

Ritcey GM (2006) Solvent extraction in hydrometallurgy: present and future. Tsinghua Sci Technol 11(2):137–152

Safarzadeh SM, Bafghi MS, Moradkhani D, Ilkhchi OM (2007) A review on hydrometallurgical extraction and recovery of cadmium from various resources. Miner Eng 20(3):211–220

Sum EYL (1991) The recovery of metals from electronic scrap. JOM 43(4):53–61

Yang B (1994) Ion exchange in organic extractant system. Ion Exch Adsorpt 10(2):168–179

European Parliament (2003) Directive 2002/96/EC of the European Parliament and of the Council of 27 January 2003 on waste electrical and electronic equipment (WEEE). Off J Eur Union L37:24–38

European Parliament (2012) Directive 2012/19/EU of the European Parliament and of the Council of 4 July 2012 on waste electrical and electronic equipment (WEEE). Off J Eur Union L197:38–71

Widmer R, Oswald-Krapf H, Sinha-Khetriwal D, Böni H, Schnellmann M (2005) Global perspectives on e-waste. Environ Impact Assess Rev 25(5):436–458. www.ChemistryWorld.org, June 2007, The gadget scrap heap: electronic waste, pp 44–48

Sharma P, Fulekar MH, Pathak B (2012) E-waste—a Challenge for Tomorrow. Res. J. of Recent Sci. 1(3):86–93

Liu Q, Li KQ, Zhao H, Li G, Fan FY (2009) The global challenge of electronic waste management. Environ Sci Pollut Res 16(3):L248–249

Shao G, Li Y, Xu X, Liu J, Wu K, Gu C (2008) The hazard of chromium exposure to neonates in Guiyu of China. Sci Total Environ 403(1–3):99–104

Blass VD, Favret L, Fuji M, Mahdavi S, Miller R, Neira, J (2006) End-of-life management of cell phones in the United States. MS Thesis, Donald Bren School of Environmental Science and Management University of California, Santa Barbara, CA

Robinson B (2009) E-waste: an assessment of global production and environmental impacts. Sci Total Environ 408:183–191

Schmidt CW (2002) E-junk explosion. Environ, Health Perspectives, p 110

Yang GCC (1993) Environmental threats of discarded picture tubes and printed circuit boards. J Hazard Mater 34:235–243

Kasassi A, Rakimbei P, Karagiannidis A, Zabaniotou A, Tsiouvaras K, Nastis A, Tzafeiropoulou K (2008) Soil contamination by heavy metals: measurements from a closed unlined landfill. Bioresour Technol 99:8578–8584

Qasim SR, Chiang W (1994) Sanitary landfill leachate: generation, control and treatment. CRC Press, New York

Lee JC, Song HT, Yoo JM (2007) Present status of the recycling of waste electrical and electronic equipment in Korea. Resour Conserv Recycl 50:380–397

Bi X, Simoneit BRT, Wang Z, Wang X, Sheng G, Fu J (2010) The major components of particles emitted during recycling of waste printed circuit boards in a typical e-waste workshop of South China. Atmos Environ 44(35):4440–4445

Luo C, Liu C, Wang Y, Liu X, Li F, Zhang G, Li X (2011) Heavy metal contamination in soils and vegetables near an e-waste processing site, south China. J Hazard Mater 186(1):481–490

Owens CJ, Lambright C, Bobseine K, Ryan B, Gray LJ, Gullett BK, Wilson VS (2007) Identification of estrogenic compounds emitted from the combustion of computer printed circuit boards in electronic waste. Environ Sci Technol 41(24):8506–8511

Funcke W, Hemminghaus HJ (1997) PXDF/D in flue gas from an incinerator charging wastes containing Cl and Br and a statistical description of the resulting PXDF/D combustion profiles. Organohalogen Compds 31:93–98

Stewart ES, Lemieux PM (2003) Emissions from the incineration of electronics industry waste. In: IEEE international symposium on proceedings of electronics and the environment, pp 271–275

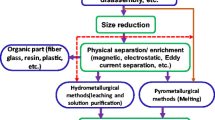

Ari V (2016) A review of technology of metal recovery from electronic waste, Ch. 6. In: Florin-Constantin Mihai (ed) E-Waste in Transition - From Pollution to Resource. https://doi.org/10.5772/61569

Cui J, Forssberg E (2003) Mechanical recycling of waste electric and electronic equipment: a review. J Hazard Mater 99(3):243–263

Li J, Shrivastava P, Gao Z, Zhang HC (2004) Printed circuit board recycling: a state of the art survey. IEEE Trans Electron Pack Manuf 27(1):33–42

Taberman SO, Carlsson B, Erichson H, Brobech J, Gregersen JC (1995) Environmental consequences of incineration and landfilling of waste from electronic equipment. The Nordic Council of Ministers, Copenhagen

Jianzhi L, Shrivastava P, Gao Z, Zhang HC (2004) Printed circuit board recycling: a state-of-the-art survey. IEEE Trans Electron Pack 27:33–42

Yang T, Zhu P, Liu W, Chen L, Zhang D (2017) Recovery of tin from metal powders of waste printed circuit boards. Waste Manag 68:449–457

Guo JY, Guo J, Xu ZM (2009) Recycling of non-metallic fractions from waste printed circuit boards: a review. J Hazard Mater 168(2–3):567–590

Kasper AC, Berselli GBT, Freitas BD, Tenório JAS, Bernardes AM, Veit HM (2011) Printed wiring boards for mobile phones: characterization and recycling of copper. Waste Manag 31:2536–2545

Tan Z, He Y, Xie W, Zhou E, Zheng Y (2011) Size distribution of wet crushed waste printed circuit boards. Min Sci Technol (China) 21:359–363

Tilmatine A, Medles K, Bendimerad SE, Boukholda F, Dascalescu L (2009) Electrostatic separators of particles: application to plastic/metal, metal/metal and plastic/plastic mixtures. Waste Manag 29:228–232

Ortiifio N, Conesa JA, Molto J et al (2014) Pollutant emissions during pyrolysis and combustion of waste printed circuit boards, before and after metal removal. Sci Total Environ 499:27–35

Yang XN, Sun LS, Xiang J et al (2013) Pyrolysis and dehalogenation of plastics from waste electrical and electronic equipment (WEEE): a review. Waste Manag 33(2):462–473

Ghosh B, Ghosh MK, Parhi P, Mukherjee PS, Mishra BK (2015) Waste printed circuit boards recycling: an extensive assessment of current status. J Clean Prod 94:5–19

Cocchiaraa C, Piazza S, Sunseri C, Inguanta R (2017) Study of a novel electrochemical method for copper recovery from waste printed circuit boards. Chem Eng Trans 57:2017

Zhou PG, Zheng Z, Peng XC et al (2007) Leaching of copper from printed circuit board by Thiobacillus ferrooxidans. Environ Pollut Control 29(2):119–122 (in Chinese)

Dorella G, Mansur MB (2007) A study of the separation of cobalt from spent Li-ion battery residues. J Power Sources 170:210–215

Lister TE, Wang P, Anderko A (2014) Recovery of critical and value metals from mobile electronics enabled by electrochemical processing. Hydrometallurgy 149:228–237

Pranolo Y, Zhang W, Cheng CY (2010) Recovery of metals from spent lithium-ion battery leach solutions with a mixed solvent extractant system. Hydrometallurgy 102:37–42

Provazi Campos BA, Espinosa DCR, Tenório JAS (2011) Metal separation from mixed types of batteries using selective precipitation and liquid–liquid extraction techniques. Waste Manag 31:59–64

Herat S, Agamuthu P (2012) E-waste: a problem or an opportunity Review of issues, challenges and solutions in Asian countries. Waste Manag Res (11):1113–1129. https://doi.org/10.1177/0734242X1245337

Kaya M (2016) Recovery of metals and nonmetals from electronic waste by physical and chemical recycling processes. Waste Manag 57:64–90

Raphulu MC, Scurrell MS (2015) Cyanide leaching of gold catalysts. Catal Commun 67:87–89

Wang WD, Feng YL, Li HR, Yang ZC, Zhang X, Yi AF (2015) Recovering gold from cyanide residue by alkaline predesilication-cyanide leaching technique. Chin J Nonferrous Met 25(1):233–240

Behnamfard A, Salarirad MM, Veglio F (2013) Process development for recovery of copper and precious metals from waste printed circuit boards with emphasize on palladium and gold leaching and precipitation. Waste Manage 33(11):2354–2363

Ghasem A, Khoramnejadian S (2015) The extraction of gold from e-waste by hydrometallurgy. Orient J Chem 31(1):113–120

Kannan G, Prabhakaran D, Sivakumar P, Thirumarimurugan M (2014) Recovery of metals from electronic waste using electrowinning process. J Chem Pharm Sci 4:136–137

Chen M, Huang J, Ogunseitan OA, Zhu N, Wang Y (2015) Comparative study on copper leaching from waste printed circuit boards by typical ionic liquid acids. Waste Manag 41:142–147

Gonçalves MCA, Garcia EM, Taroco HA, Gorgulho HF, Melo JOF, Silva RRA, Souza AG (2015) Chemical recycling of cell phone Li-ion batteries: application in environmental remediation. Waste Manag 40:144–150

Navarro M, May PM, Hefter G, Konigsberger E (2014) Solubility of CuO(s) in highly alkaline solutions. Hydrometallurgy 147:68–72

Pant D, Singh P, Upreti MK (2014) Metal leaching from cathode ray tube waste using combination of Serratia plymuthica and EDTA. Hydrometallurgy 146:89–95

Sahni A, Kumar A, Kumar S (2016) Chemo-biohydrometallurgy—a hybrid technology to recover metals from obsolete mobile SIM cards. Environ Nanotechnol Monit Manag 6:130–133

Gurung M, Adhikari BB, Kawakita H, Ohto K, Inoue K, Alam S (2013) Recovery of gold and silver from spent mobile phones by means of acidothiourea leaching followed by adsorption using biosorbent prepared from persimmon tannin. Hydrometallurgy 133:84–93

Jadhao P, Chauhan G, Pant KK, Nigam KDP (2016) Greener approach for the extraction of copper metal from electronic waste. Waste Manag 57:102–112

Madrigal AJ, Argumedo DR, Alarcón A, Mendoza-L R, Barradas O, Cruz SJ, Ferrera-C R, Jiménez-F M (2015) Bioleaching of gold, copper and nickel from waste cellular phone PCBs and computer gold finger motherboards by two Aspergillus niger strains. Braz J Microbiol 46:707–713

Pociecha M, Lestan D (2012) Recycling of EDTA solution after soil washing of Pb, Zn, Cd and As contaminated soil. Chemosphere 86(8):843–846

Li L, Dunn JB, Zhang XX, Gaines L, Chen RJ, Wu F, Amine K (2013) Recovery of metals from spent lithium-ion batteries with organic acids as leaching reagents and environmental assessment. J Power Sources 233:180–189

Di-Palma L, Mecozzi R (2007) Heavy metals mobilization from harbour sediments using EDTA and citric acid as chelating agents. J Hazard Mater 147(3):768–775

Kolenčík M, Urík M, Čerňanský S, Molnárová M, Matúš P (2013) Leaching of zinc, cadmium, lead and copper from electronic scrap using organic acids and the Aspergillus niger strain. Fresenius Environ Bull 22:3673–3679

Gadd GM (1999) Fungal production of citric and oxalic acid: importance in metal speciation: physiology and biogeochemical processes. Adv Microb Physiol 41:47–92

Lu Y, Xu Z (2016) Precious metals recovery from waste printed circuit boards: a review for current status and perspective. Resour Conserv Recycl 113:28–39

Park Y, Fray D (2009) Recovery of high purity precious metals from printed circuit boards. J Hazard Mater 164:1152–1158

Li, J., Dong, Q., Liu, L., Song, Q., 2016. Measuring treatment costs of typical waste electrical and electronic equipment: a pre-research for Chinese policy making. Waste Manage 57:36–45

Li J, Lu H, Guo J, Xu Z, Zhou Y (2007) Recycle technology for recovering resources and products from waste printed circuit boards. Environ Sci Technol 41:1995–2000

Waton J, Younas I (1998) Superconducting discs as permanent magnets for magnetic separation. Mater Sci Eng B 53:220–224

Lungu M, Schlett Z (2001) Vertical drum eddy-current separator with permanent magnets. Int J Miner Process 63:207–216

Zhang S, Rem P (1999) Particle trajectory simulation of two-drum eddy current separators. Resour Conserv Recycl 26:71–90

Meng L, Gao J, Zhong Y, Wang Z, Chen K, Guo Z (2018) Supergravity separation for recovering Pb and Sn from electronic waste. Sep Purif Technol 191:375–383

Lee J, Kim Y, Lee JC (2012) Disassembly and physical separation of electric/electronic components layered in printed circuit boards (PCB). J Hazard Mater 241–242:387–394

Habib M, Miles NJ, Hall P (2013) Recovering metallic fractions from waste electrical and electronic equipment by a novel vibration system. Waste Manag 33:722–729

Zhou YH, Qiu KQ (2010) A new technology for recycling materials from waste printed circuit boards. J Hazard Mater 175:823–828

Estrada-Ruiz RH, Flores-Campos R, Gamez-Altamirano HA, Velarde-Sanchez EJ (2016) Separation of the metallic and non-metallic fraction from printed circuit boards employing green technology. J Hazard Mater 311:91–99

Zhang ZY, Zhang FS, Yao TQ (2017) An environmentally friendly ball milling process for recovery of valuable metals from E-waste scraps. Waste Manag 68:490–497

Tsydenova O, Bengtsson M (2011) Chemical hazards associated with treatment of waste electrical and electronic equipment. Waste Manag 31(1):45–58

Chehade Y, Siddique A, Alayan H, Sadasivam N, Nusri S, Ibrahim T (2012) Recovery of gold, silver, palladium, and copper from waste printed circuit boards. In: Proceedings of the international conference on chemical, civil and environment engineering (ICCEE), Dubai, United Arab Emirates, pp 24–25

Delfini M, Ferrini M, Manni A, Massacci P, Piga L (2011) Antonio Scoppettuolo optimization of precious metal recovery from waste electrical and electronic equipment boards. J Environ Prot 2:675–682

Dhawan N, Kumar V, Kumar M (2009) Recovery of metals from electronic scrap by hydrometallurgical route. In: Howard SM (ed.) EPD Congress 2009. TMS, Warrendale, PA, pp 1107–1109

Shamsuddin M (1986) Metal recovery from scrap and waste. J Met 38(2):24–31

Tavlarides LL, Bae JH, Lee CK (1985) Solvent extraction, membranes, and ion exchange in hydrometallurgical dilute metals separation. Sep Sci Technol 22(2–3):581–617

Paretsky VM, Antipov NI, Tarasov AV (2004) Hydrometallurgical method for treating special alloys, jewelry, electronic and electrotechnical scrap. In: Proceedings of the Minerals, Metals & Materials Society (TMS) annual meeting, Charlotte, NC, 14–18 March, pp 713–721

Neto IFF, Sousa CA, Brito MSCA, Futuro AM, Soares HMVM (2016) A simple and nearly-closed cycle process for recycling copper with high purity from end life printed circuit boards. Sep Purif Technol 164:19–27

Kumari A, Jha MK, Lee JC, Singh RP (2016) Clean process for recovery of metals and recycling of acid from the leach liquor of PCBs. J Clean Prod 112:4826–4834

Jiang P, Harney M, Song Y, Chen B, Chen B, Chen Q, Chen T, Lazarus G, Lawrence HD, Korzenski MB (2012) Improving the end-of-life for electronic materials via sustainable recycling methods. Proc Environ Sci 16:485–490

Zhang ZY, Zhang FS (2014) A green process for copper recovery from waste printed circuit boards. Adv Mater Res 878:374–379

Zhang ZY, Zhang FS (2014) Selective recovery of palladium from waste printed circuit boards by a novel non-acid process. J Hazard Mater 279:46–51

Hilson G, Monhemius AJ (2006) Alternatives to cyanide in the gold mining industry: what prospects for the future? J Clean Prod 14:1158–1167

La Brooy SR, Linge HG, Walker GS (1994) Review of gold extraction from ores. Miner Eng 7:1213–1241

Brombacher CH, Bachofen R, Brandl H (1998) Development of a laboratory-scale leaching plant for metal extraction from fly ash by Thiobacillus strains. Appl Environ Microbiol 64(4):1237

Mishra D, Dong JK, Ralph DE, Jong-Hwan AHN, Young HAR (2008) Bioleaching of spent hydro-processing catalyst using acidophilic bacteria and its kinetics aspect. J Hazard Mater 152(3):1082–1091

Ilyas S, Anwar MA, Niazi SB, Ghauri MA (2007) Bioleaching of metals from electronic scrap by moderately thermophilic acidophilic bacteria. Hydrometallurgy 88(1–4):180

Kinnunen PHM, Heimala S, Vanhanen ML, Puhakka J (2006) Chalcopyrite concentrate leaching with biologically produced ferric sulphate. Biores Technol 97:1727–1734

Liu YG, Zhou M, Zeng GM, Wang LX, Fan T, Xu WH (2008) Bioleaching of heavy metals from mine tailings by indigenous sulfur-oxidizing bacteria: effects of substrate concentration. Bioresour Technol 99:4124–4129

Nakade DB (2013) Bioleaching of copper from low grade ore bornite using halophilic Thiobacillus ferrooxidans, N-11. Res J Recent Sci 2:162–166

Tipre DR, Dave SR (2004) Bioleaching process for Cu-Pb-Zn bulk concentrate at high pulp density. Hydrometallurgy 75:37–43

Zhou HB, Zeng WM, Yang ZF, Xie YJ, Qiu GZ (2009) Bioleaching of chalcopyrite concentrate by a moderately thermophilic culture in a stirred tank reactor. Bioresour Technol 100:515–520

Brandl H, Bosshard R, Wegmann M (2001) Computer-munching microbes: metal leaching from electronic scrap by bacteria and fungi. Hydrometallurgy 59:319–326

Choi MS, Cho KS, Kim DS, Kim DJ (2004) Microbial recovery of copper from printed circuit boards of waste computer by Acidithiobacillus ferrooxidans. J Environ Sci Health A 39(11–12):2973–2982

Faramarzi MA, Stagars M, Pensini E, Krebs W, Brandl H (2004) Metal solubilization from metal-containing solid materials by cyanogenic Chromobacterium violaceum. J Biotechnol 113:321–326

Debaraj M, Young HR (2010) Current research trends of microbiological leaching for metal recovery from industrial wastes. Curr Res Technol Educ Topics Appl Microbiol Microb Biotechnol 4:1289–1296

Liang G, Mo Y, Zhou Q (2010) Novel strategies of bioleaching metals from printed circuit boards (PCBs) in mixed cultivation of two acidophiles. Enzyme Microb Technol 47:322–326

Panda S, Akcil A, Pradhan N, Deveci H (2015) Current scenario of chalcopyrite bioleaching: a review on the recent advances to its heap-leach technology. Bioresour Technol 196:694–706

Wang J, Bai J, Xu J, Liang B (2009) Bioleaching of metals from printed wire boards by Acidithiobacillus ferrooxidans and Acidithiobacillus thiooxidans and their mixture. J Hazard Mater 172:1100–1105

Saidan M, Brown B, Valix M (2012) Leaching of electronic waste using biometabolised acids. Chin J Chem Eng 20:530–534

Kim MJ, Seo JY, Choi YS, Kim GH (2016) Bioleaching of spent Zn-Mn or Ni-Cd batteries by Aspergillus species. Waste Manag 51:168–173

Xu TJ, Ramanathan T, Ting YP (2014) Bioleaching of incineration fly ash by Aspergillus niger—precipitation of metallic salt crystals and morphological alteration of the fungus. Biotechnol Rep 3:8–14

Amiri F, Yaghmaei S, Mousavi SM, Sheibani S (2011) Recovery of metals from spent refinery hydrocracking catalyst using adapted Aspergillus niger. Hydrometallurgy 109:65–71

Biswas S, Bhattacharjee K (2014) Fungal assisted bioleaching process optimization and kinetics: scenario for Ni and Co recovery from a lateritic chromite overburden. Sep Purif Technol 135:100–109

Rasoulnia P, Mousavi SM (2016) V and Ni recovery from a vanadium-rich power plant residual ash using acid producing fungi: Aspergillus niger and Penicillium simplicissimum. RSC Adv 6:9139–9151

Jadhav U, Hocheng H (2015) Waste solder and printed circuit board: the emerging secondary sources for recovery of metals. Arch Mater Sci Eng 72:5–15

Yang T, Xu Z, Wen J, Yang L (2009) Factors influencing bioleaching copper from waste printed circuit boards by Acidithiobacillus ferrooxidans. Hydrometallurgy 97(1, 2):29

Mražíková A, Marcinčáková R, Kaduková J, Velgosová O, Willner J, Fornalczyk A, Saternus M (2013) The effect of specific conditions on Cu, Ni, Zn and Al recovery from PCBS waste using acidophilic bacterial strains. J Polish Miner Eng Soc 59–62

Brandle H, Lelmann S, Faramarzi MA, Martinelli D (2008) Biomobilization of silver, gold, and platinum from solid waste materials by HCN-forming microorganisms. Hydrometallurgy 94(1–4):14

Ilyas S, Ruan CH, Bhatti HN, Ghauri MA, Anwar MA (2010) Column bioleaching of metals from electronic scrap. Hydrometallurgy 101(3, 4):135

Velgosová O, Kaduková J, Marcinčáková R, Mražíková A, Fröhlich L (2014) The role of main leaching agents responsible for Ni bioleaching from spent Ni-Cd batteries. Sep Sci Technol 49:438–444

Velgosová O, Kaduková J, Marcinčáková R, Palfy P, Trpcevská J (2013) Influence of H2SO4 and ferric iron on Cd bioleaching from spent Ni–Cd batteries. Waste Manag 33:456–461

Sheel A, Pant D (2017) Recovery of gold from electronic waste using chemical assisted microbial biosorption (hybrid) technique. Bioresour Technol 247:1189–1192

Alston SM, Clark AD, Arnold JC, Stein BK (2011) Environmental impact of pyrolysis of mixed WEEE plastics Part 1: Experimental pyrolysis data. Environ Sci Technol 45:9380–9385

Zhou YH, Wu WB, Qiu KQ (2011) Recycling of organic materials and solder from waste printed circuit boards by vacuum pyrolysis-centrifugation coupling technology. Waste Manag 31:2569–2576

Zhan L, Xu Z (2009) Separating and recycling metals from mixed metallic particles of crushed electronic wastes by vacuum metallurgy. Environ Sci Technol 43:7074–7078

Zhan L, Xu Z (2011) Separating and recovering Pb from copper-rich particles of crushed waste printed circuit boards by evaporation and condensation. Environ Sci Technol 45(12):5359–5365

Zhan L, Xu Z (2012) Separating criterion of Pb, Cd, Bi and Zn from metallic particles of crushed electronic wastes by vacuum evaporation. Sep Sci Technol 47:913–919

Zhan L, Xu ZM (2008) Application of vacuum metallurgy to separate pure metal from mixed metallic particles of crushed waste printed circuit board scraps. Environ Sci Technol 42:7676–7681

He Y, Ma E, Xu Z (2014) Recycling indium from waste liquid crystal display panel by vacuum carbon-reduction. J Hazard Mater 268:185–190

Ma E, Lu R, Xu Z (2012) An efficient rough vacuum-chlorinated separation method for the recovery of indium from waste liquid crystal display panels. Green Chem 14:3395–3401

Zhan L, Xu ZM (2014) State-of-the-art of recycling e-wastes by vacuum metallurgy. Sep Environ Sci Technol 48:14092–14102

Xiu FR, Weng H, Qi Y, Yu G, Zhang Z, Chen M (2017) A novel recovery method of copper from waste printed circuit boards by supercritical methanol process: preparation of ultrafine copper materials. Waste Manag 60:643–651

Xue M, Yan G, Li J, Xu Z (2012) Electrostatic separation for recycling conductors, semiconductors, and nonconductors from electronic waste. Environ Sci Technol 46(19):10556–10563

Acknowledgements

The authors are grateful to the Central Metallurgical R&D Institute for providing financial support to this work under Grant No. ID 72/2018.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

No competing financial interest is declared.

Additional information

The contributing editor for this article was Bernd Friedrich.

Rights and permissions

About this article

Cite this article

Abdelbasir, S.M., El-Sheltawy, C.T. & Abdo, D.M. Green Processes for Electronic Waste Recycling: A Review. J. Sustain. Metall. 4, 295–311 (2018). https://doi.org/10.1007/s40831-018-0175-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40831-018-0175-3