Abstract

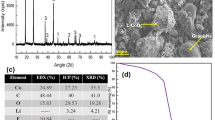

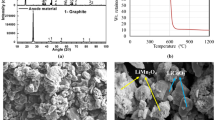

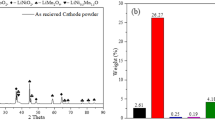

The short lifespan and massive accumulation of discarded lithium-ion batteries (LIBs) along with the significant presence of lithium and cobalt values are key facts for recycling. The discarded LIBs were ground in disc mill and sieved to separate steel case, aluminum, and copper foils from the active material. The minus 53 µm fraction was considered as an active material and XRD analysis revealed LiCoO2 and graphite around 50% (w/w). The active material was carbothermally reduced in a muffle furnace at atmospheric conditions for a predetermined time (5–45 min) and temperature (500–900 °C) and the reduced mass was leached in distilled water for 30 min followed by wet magnetic separation. It was found that the magnetic fraction contains almost 90% cobalt values, non-magnetic majorly containing graphite and other impurities such as Mn, Cu, and Al and precipitated salt contains lithium carbonate. This study demonstrates a simple, environment friendly, and flexible process which includes indigenous carbothermal reduction of the active material, selective dissolution of lithium carbonate, and subsequently wet magnetic separation to recover cobalt values in a short time.

Similar content being viewed by others

References

Zeng X, Li J, Singh N (2014) Recycling of spent lithium-ion battery: A critical review. Crit Rev Environ Sci Technol 44:1129

Poyraz AS, Huang J, Cheng S, Bock DC, Wu L, Zhu Y, Marschilok AC, Takeuchi KJ, Takeuchi ES (2016) Effective recycling of manganese oxide cathodes for lithium based batteries. Green Chem 18:3414

Takacova Z, Havlik T, Kukurugya F, Orac D (2016) Cobalt and lithium recovery from active mass of spent Li-ion batteries: Theoretical and experimental approach. Hydrometallurgy 9:163

Indian Bureau of Mines, Indian Minerals Yearbook, (Part-II: Metals & alloys) (2018)

Maschler TG, Friedrich B, Weyhe R, Heegn H, Rutz M (2012) Development of a recycling process for Li-ion batteries. J Power Sources 173:207

Meshram P, Pandey BD, Mankhand TR (2014) Extraction of lithium from primary and secondary sources by pre-treatment, leaching and separation: A comprehensive review. Hydrometallurgy 150:192

Hu J, Zhang J, Li H, Chen Y, Wang C (2017) A promising approach for the recovery of high value-added metals from spent lithium-ion batteries. J Power Sources 351:192

Chen X, Ma X, Luo C, Zhou T (2017) Recovery of valuable metals from waste cathode materials of spent lithium-ion batteries using mild phosphoric acid. J Hazard Mater 326:77

Zeng X, Li J, Shen B (2015) Novel approach to recover cobalt and lithium from spent lithium-ion battery using oxalic acid. J Hazard Mater 295:112

Shuva MAH, Kurny ASW (2013) Hydrometallurgical recovery of value metals from spent lithium ion batteries. Am J Mater Eng Technol 1:8

Chen X, Chen Y, Zhou T, Liu D, Hu H, Fan S (2015) Hydrometallurgical recovery of metal values from sulfuric acid leaching liquor of spent lithium-ion batteries. Waste Manag 38:349

Li L, Ge J, Wu F, Chen R, Chen S, Wu B (2010) Recovery of cobalt and lithium from spent lithium ion batteries using organic citric acid as leachant. J Hazard Mater 176:288

Jia L, Guang X, Wang Z, Zhenming X (2016) Environmentally-friendly oxygen-free roasting/wet magnetic separation technology for in situ recycling cobalt, lithium carbonate and graphite from spent LiCoO2/graphite lithium batteries. J Hazard Mater 302:97

Huang Z, Ruan JJ, Yuan ZH, Qiu RL (2018) Characterization of the Materials in waste power banks and the green recovery process. ACS Sustain Chem Eng 6(3):3815

Xiao JF, Li J, Xu ZM (2017) Novel approach for in situ recovery of lithium carbonate from spent lithium ion batteries using vacuum metallurgy. Environ Sci Technol 51(20):11960

Kipouros G, Sadoway D (1998) Toward new technologies for the production of lithium. JOM 50:24

Grass RN, Stark WJ (2006) Gas phase synthesis of fcc-cobalt nanoparticles. J Mater Chem 16:1825

Prabaharan G, Barik SP, Kumar N, Kumar L (2017) Electrochemical process for electrode material of spent lithium ion batteries. Waste Manag 68:527

Yu J, He Y, Ge Z, Li H, Xie W, Wang S (2018) A promising physical method for recovery of LiCoO2 and graphite from spent lithium-ion batteries: Grinding flotation. Sep Purif Technol 190:45

Acknowledgement

The authors would like to acknowledge the funding received from the Indian Institute of Technology, Roorkee, through Faculty Initiation Grant.

Author information

Authors and Affiliations

Corresponding author

Additional information

The contributing editor for this article was Bernd Friedrich.

Rights and permissions

About this article

Cite this article

Vishvakarma, S., Dhawan, N. Recovery of Cobalt and Lithium Values from Discarded Li-Ion Batteries. J. Sustain. Metall. 5, 204–209 (2019). https://doi.org/10.1007/s40831-018-00208-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40831-018-00208-4