Abstract

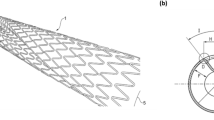

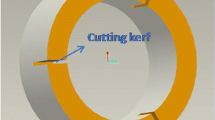

Shape setting is a fundamental step of NiTi components manufacturing. It is undertaken for fixing programmed shapes and for optimizing both the shape memory and the superelastic properties of SMA. Conventional NiTinol shape setting is performed by constraining the material in furnace where it is heat treated completely, and thus local component functionalization is not allowed. Recently, it has been demonstrated the feasibility of fast laser shape setting of straight thin NiTinol wires to induce a superelastic behavior comparable to the commercial wires. This work reports the use of a laser beam for promoting a local superelasticity in a NiTi diamond-like strut. In details, the struts were cut from a cold worked NiTi thin tape, and then a focused laser heating was implemented just on the parts of the element in which the superelasticity is strictly required. Thermo-mechanical testing of the struts, after local laser process conditions, indicates that a laser beam scanning is suitable for provoking local microstructure modifications, which enables the superelastic functioning of the strut-like element. Scanning electron microscopy has shown that residual martensite variants, present in the cold worked material, disappear in the portion of the diamond elements where the laser beam passed.

Similar content being viewed by others

References

Otsuka K, Wayman CM (1998) Shape memory materials. Cambridge University Press, Cambridge

Casati R, Vedani M, Tuissi A (2014) Thermal cycling of stress-induced martensite for high-performance shape memory effect. Scr Mater 80:13

Hodgson DE (2001) In: SMST-2000 Conference proceedings, pp 11–24

Duerig T, Pelton AR, Stockel D (1999) An overview of nitinol medical applications. Mater Sci Eng A273:149–160

Jani JM, Leary M, Subic AS, Gibson MA (2014) A review of shape memory alloy research, applications and opportunities. Mater Des 56:1078–1113

Pelton AR, DiCello J, Miyazaki S (2001) In: SMST-2000 conference proceedings, pp 361–374

Perkins J, Sponholz RO (1984) Stress-induced martensitic transformation cycling and two-way shape memory training in Cu-Zn-Al alloys. Metall Trans A 15A:313–321

Yiong L, Youn L, Van Humbeeck J (1999) Two-way shape memory effect developed by martensite deformation in NiTi. Acta Mater 47–1:199–209

Contardo L, Guenin G (1990) Training and two way memory effect in Cu-Zn-Al alloy. Acta Metall Mater 38–7:1267–1272

Tuissi A, Bassani P, Mangioni A, Toia L, Buttera F (2005) In: SMST 2004 proceedings of the international conference on shape memory and superelastic technologies, pp 501–508

Lin HC, Wu SK, Chou TS, Kao HP (1991) The effects of cold rolling on the martensitic transformation of an equiatomic TiNi alloy. Acta Metall Mater 38:2069–2080

Meng Q, Liu Y, Yang H, Shariat BS, Nam T (2012) Functionally graded NiTi strips prepared by laser surface anneal. Acta Mater 60:1658–1668

Biffi CA, Casati R, Tuissi A (2016) Laser shape setting of thin NiTi wires. Smart Mater Struct 25:01LT02. https://doi.org/10.1088/0964-1726/25/1/01LT02

Biffi CA, Coduri M, Casati R, Tuissi A (2015) In: ASME 2015 conference on smart materials, adaptive structures and intelligent systems. Colorado Springs, Colorado, USA, September 21–23, 2015. ISBN: 978-0-7918-5729-8. No. SMASIS2015-8917, ppV001T01A008. https://doi.org/10.1115/smasis2015-8917

Tuissi A, Coduri M, Biffi CA (2017) Laser shape setting of superelastic nitinol wires: functional properties and microstructure. Funct Mater Lett 10:1740008

Oliveira JP, Zeng Z, Omori T, Zhou N, Miranda RM, Braz Fernandez FM (2016) Improvement of damping properties in laser processed superelastic Cu-Al-Mn shape memory alloys. Mater Des 98:280–284

Welp EG, Langbein S (2008) Survey of the in situ configuration of cold-rolled, nickel-rich NiTi sheets to create variable component functions. Mater Sci Eng, A 481–482:602–605

Bellouard Y (2008) Shape memory alloys for microsystems: a review from a material research perspective. Mater Sci Eng, A 481–482:582–589

Li G, Nikumb S, Wong F (2006) An optimal process of femtosecond laser cutting of NiTi shape memory alloy for fabrication of miniature devices. Opt Lasers Eng 44–10:1078–1087

Chia-Hung Hung C-H, Chang T-L, Huang K-W, Lian P-C (2015) Micromachining NiTi tubes for use in medical devices by using a femtosecond laser. Opt Lasers Eng 66:34–40

Biffi CA, Tuissi A (2017) Nitinol laser cutting: microstructure and functional properties of femtosecond and continuous wave laser processing, smart materials and structures. Smart Mater Struct 26:035006

Meijer J, Du K, Gillner A, Hoffmann D, Kovalenko VS, Masuzawa T, Ostendorf A, Poprawe R, Schulz W (2002) Laser machining by short and ultrashort pulses, state of the art and new opportunities in the age of the photons. CIRP Ann Manuf Technol 51(2):531–550

Muhammad N, Li L (2012) Underwater femtosecond laser micromachining of thin nitinol tubes for medical coronary stent manufacture. Appl Phys A 107:849–861

Mitwally M, Farag M (2009) Effect of cold work and annealing on the structure and characteristics of NiTi alloy. Mater Sci Eng, A 519:155–166

Miller DA, Lagoudas DC (2001) Influence of cold work and heat treatment on the shape memory and plastic strain development of NiTi. Mater Sci Eng, A 308:161–175

Acknowledgements

The authors wish to thank G. D’Amelio from Optoprim srl-Italy for the support in femtosecond laser cutting experiments. This work was developed in the framework of ‘‘FHfFC: Future Home for Future Communities” project, sponsored by Regione Lombardia.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Biffi, C.A., Mathivanan, K. & Tuissi, A. Laser-Induced Superelasticity in NiTinol Stent Strut. Shap. Mem. Superelasticity 4, 377–382 (2018). https://doi.org/10.1007/s40830-018-0183-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40830-018-0183-y