Abstract

The operating conditions of the automotive three-way catalyst (TWC) are characterized by continuous variation of the air-fuel ratio (λ) that determines the composition of the exhaust supplied to the catalyst. It is well known that the ability of the TWC to simultaneously catalyze reduction of NOx and oxidation of CO and hydrocarbons is sensitive to the air-fuel ratio. In efforts to formulate improved TWCs with greater activity at lower temperatures, the impact of air-fuel ratio on light-off temperature must therefore be considered. This paper reports an investigation of the impact of air-fuel ratio on the temperatures at which representative exhaust species in a simulated exhaust mixture reach 90% conversion (T90) over a family of rhodium-based model catalysts, with focus on the performance of a recently developed catalyst comprising rhodium supported on titania-modified alumina with exceptional light-off performance. Over a range of air-fuel ratios 0.977 < λ < 1.005, the T90 for CO is nearly insensitive to λ; the T90 for NO is constant for λ < 0.995 but increases by > 200 °C between 0.995 < λ < 1.001 and 90% conversion is not achieved at any temperature for λ > 1.001; and the T90s for representative hydrocarbons ethylene, propylene, and propane decrease by more than 100 °C between 0.977 < λ < 0.995, then increase again by 30 °C (propylene) to 180 °C (propane) between 0.998 < λ < 1.001. These dramatic shifts in T90 over a small range of air-fuel ratio are attributed to facile conversion of CO and olefins by oxidation, facile conversion of propane by steam reforming, and inhibition of propane steam reforming by both oxygen and CO. Balancing these factors leads to optimal conversion of all exhaust components at an air-fuel ratio λ ~ 0.995.

Similar content being viewed by others

References

40 CFR Parts 79, 80, 85, 86, 600, 1036, 1037, 1039, 1042, 1048, 1054, 1065, and 1066. Control of air pollution from motor vehicles: tier 3 motor vehicle emission and fuel standards. Federal Register 79, 23414-23886 (2014). Government Publishing Office

M. Zammit, C. Di Maggio, C. Kim, C. Lambert, C. G. Muntean, G. C. Peden, J. Parks, K. Howden. Future automotive aftertreatment solutions: The 150°C Challenge Workshop Report. (National Technical Information Service, U.S. Department of Commerce, 5285 Port Royal Rd., Springfield, VA 22161.) pdf

Seo, C.Y., Yi, E., Nahata, M., Laine, R.M., Schwank, J.W.: Facile, one-pot synthesis of Pd@CeO2 core@shell nanoparticles in aqueous environment by controlled hydrolysis of metalloorganic cerium precursor. Mater. Lett. 206, 105–108 (2017)

Skoglundh, M., Fridell, E.: Strategies for enhancing low-temperature activity. Top. Catal. 28(1-4), 79–87 (2004)

Binder, J., Toops, T.J., Parks II, J.E., Dai, S.: Low temperature CO oxidation over ternary oxide with high resistance to hydrocarbon inhibition. Angew. Chem. Int. Ed. 54(45), 13263–13267 (2015)

Theis, J., Getsoian, A., Lambert, C.: The development of low temperature three-way catalysts for high efficiency gasoline engines of the future. SAE International Journal of Fuels and Lubricants. 10(2), 583–592 (2017). https://doi.org/10.4271/2017-01-0918

Chen, H.-Y., Chang, H.-L.: Development of low-temperature three-way catalysts for future fuel efficient vehicles. Johnson Matthey Technology Review. 59(1), 64–67 (2015)

Shelef, M., McCabe, R.W.: Twenty-five years after introduction of automotive catalysts: what next? Catal. Today. 62(1), 35–50 (2000)

40 CFR Part 86. Emission durability procedures for new light-duty vehicles, light-duty trucks and heavy-duty vehicles. Federal Register 69, 17531 (2004). Federal Register

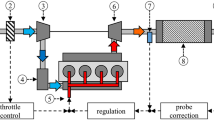

J. S. Hepburn, D. A. Dobson, C. P. Hubbard, K. Otto. The pulse flame combustor revisited. Society of Automotive Engineers Tech. Pap. Ser. 1996-10-2118 (1996). https://doi.org/10.4271/962118

J. Theis, A. Getsoian, C. Lambert. The development of low temperature three-way catalysts for high efficiency gasoline engines of the future: part II. SAE International Journal of Fuels and Lubricants (2018, accepted)

Advanced Combustion and Emission Control Low Temperature Technical Team. Aftertreatment protocols for catalyst characterization and performance evaluation: low-temperature oxidation catalyst test protocol. United States Council for Automotive Research: Southfield, MI (2015). https://cleers.org/low-temperature-protocols/

S. Bohac, J. Gaudet, J. Hoard. Effect of air-fuel ratio on engine-out exhaust hydrocarbon species from a direct injected gasoline engine. CLEERS Workshop, Ann Arbor, MI, April 6-8, 2016. https://cleers.org/wp-content/uploads/formidable/3/2016CLEERS_Bohac.pdf

C. N. Montreuil, S. C. Williams, A. A. Adamczyk. Modeling current generation catalytic converters: laboratory experiments and kinetic parameter optimization—steady state kinetics. Society of Automotive Engineers Technical Paper Series 920096 (1992)

Gopinath, C.S., Zaera, F.: NO+CO+O2 reaction kinetics on Rh(111): a molecular beam study. J. Catal. 200(2), 270–287 (2001)

Granger, P., Dhainaut, F., Pietrzik, S., Malfoy, P., Mamede, A.S., Leclerq, L., Leclerq, G.: An overview: comparative kinetic behaviors of Pt, Rh and Pd in the NO+CO and NO+H2 reactions. Top. Catal. 39(1-2), 65–76 (2006)

Burch, R., Breen, J.P., Meunier, F.C.: A review of the selective reduction of NOx with hydrocarbons under lean-burn conditions with non-zeolitic oxide and platinum group metal catalysts. Appl. Catal. B Environ. 39(4), 283–303 (2002)

Gustafson, J., Mikkelsen, A., Borg, M., Lundgren, E., Köhler, L., Kresse, G., Schmid, M., Varga, P., Yuhara, J., Torrelles, X., Quirós, C., Andersen, J.N.: Self-limited growth of a thin oxide layer on Rh(111). Phys. Rev. Lett. 92(12), 126102 (2004)

Chin, Y.-H., Iglesia, E.: Elementary steps, the role of chemisorbed oxygen, and the effects of cluster size in catalytic CH4-O2 reactions on palladium. J. Phys. Chem. C. 115(36), 17845–17855 (2011)

García-Diéguez, M., Chin, Y.-H., Iglesia, E.: Catalytic reactions of dioxygen with ethane and methane on platinum clusters: mechanistic connections, site requirements, and consequences of chemisorbed oxygen. J. Catal. 285(1), 260–272 (2012)

Chin, Y.-H., Buda, C., Neurock, M., Iglesia, E.: Consequences of metal-oxide interconversion for C-H bond activation during CH4 reactions on Pd catalysts. J. Am. Chem. Soc. 135(41), 15425–15442 (2013)

Phatak, A., Koryabkina, N., Rai, S., Ratts, J.L., Ruettinger, W., Farrauto, R.J., Blau, G.E., Delgass, W.N., Ribeiro, F.H.: Kinetics of the water-gas shift reaction on Pt catalysts supported on alumina and ceria. Catal. Today. 123(1-4), 224–234 (2007)

Grabow, L.C., Gokhale, A.A., Evans, S.T., Dumesic, J.A., Mavrikakis, M.: Mechanism of the water gas shift reaction on Pt: first principles, experiments, and microkinetic modeling. J. Phys. Chem. C. 112(12), 4608–4617 (2008)

Acknowledgments

The authors thank Dr. Todd Toops, Dr. Eleni Kyriakidou, Dr. Andrew Binder, Dr. Johannes Schwank, Dr. Galen Fisher, Dr. John Hoard, and Dr. Chang-Yup Seo for helpful discussions.

Funding

This research was sponsored by the U.S. Department of Energy, Office of Energy Efficiency and Renewable Energy, Vehicle Technologies Office, Propulsion Materials Program under grant DE-EE0006845. The work reported here was presented at the Cross-Cut Lean Exhaust Emissions Reduction Simulations (CLEERS) 2017 Workshop. CLEERS is an initiative funded by the U.S. Department of Energy Vehicle Technologies Office and coordinated by a committee of industry and national laboratory representatives.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no competing interests.

Rights and permissions

About this article

Cite this article

Getsoian, A.B., Theis, J.R. & Lambert, C.K. Sensitivity of Three-Way Catalyst Light-Off Temperature to Air-Fuel Ratio. Emiss. Control Sci. Technol. 4, 136–142 (2018). https://doi.org/10.1007/s40825-018-0089-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40825-018-0089-3