Abstract

In this globalized scenario, the overall performance of the manufacturing industries is the backbone of the development of the countries’ economies. In this research, the authors’ main objective of the study is to segment the manufacturing industries by using the triangular interval-valued fuzzy TOPSIS Method and find out the factors determining its performance. The researchers have collected the data from 350 manufacturing industries located in Puducherry, India. They applied a Simple Random sampling method by using a structured questionnaire from manufacturing industries. To analyze the data, the researchers used software packages like Excel, SPSS and LISREL 8.72. The researchers applied Confirmatory Factor Analysis, Triangular Interval-Valued Fuzzy TOPSIS Method, Chi square and Correspondent Analysis to conclude the result. Based on the factors loadings of the items, the contribution made by the items in respect of Performance may be ranked as Sales growth, Market share, Profit margin and Return on investment. With the help of Triangular Interval-Valued Fuzzy TOPSIS Method researchers segmented the manufacturing industries into three groups and by using the Chi square analysis the researchers found that the five demographics characteristics like Number of years in Business (Company), Scale of industry, Kind of manufacturing, Number of employees and location of the production plant of the respondents and these are significantly associated with segmenting the manufacturing industries and determine the performance of manufacturing industries.

Similar content being viewed by others

Introduction

Performance measurement helps the manufacturing industries to evaluate the trend in success and failure of the organization. Performance measurement refers to the assessment of the activities of an enterprise during a particular period. It is an appraisal of the success or failure of the activities of an enterprise during a given period [25, 26]. To continue to be competitive in these days’ difficult environment, manufacturing organizations have to attain safe and most system performance with minimal downtime. Powerful upkeep strategies can make considerable contributions to manufacturing performance, plant availability, reliability and organizational profitability [19]. It seems at the activity effect of generation, in which manufacturing technologies are considered as one of the important in today’s situation. They discover no proof of era destroying jobs, rather their proof is suggestive of it transferring jobs from intermediary skill to high ability jobs. While generation has caused a growth in capital intensity, it has now not reduced mixture employment in Indian manufacturing [4]. Frequent modifications passed off within the economy round the sector with the marketplace becoming touchy to the price has led increasingly more the agencies to attain better consequences, requiring to look of differentiators inside the tactics of manufacturing that better the overall performance continuously [2, 22].

An enterprise that is managing to accomplish a higher return on assets and investment shall automatically manage to have a high-profit margin. Similarly, an operationally efficient firm will be able to increase the level of turnover, which will enable it to penetrate more markets and thereby result in an increase in market share [8, 15]. Market percentage loved with the aid of an organization and its financial performance and status is vital for the survival of any enterprise [1, 28]. Literature shows that all enterprises placing good emphasis on competitive items related to the process of manufacturing shall be performing financially well [10]. Past studies have concentrated on assessing the performance of undertakings through various profitability ratios such as return on sales, operating income to sales, operating income to an asset, return on assets, etc. [3, 23, 29, 31]. Pagell and Krause [24] have expressed a very interesting observation that enterprises may not react to a turbulent environment with enhanced flexibility, which shall enhance their business performance.

Some researchers have included a perceived performance method to assess the performance of firms. In this method, data can be obtained from the Chief Executives, Managing Directors, General Managers and Senior Level Managers of the manufacturing firms by asking them to rate the performance of their respective firms over a given period by making an intra-firm or inter-firm comparisons [7, 11]. Ketokivi and Schroeder [21] conducted an analytical study about the effectiveness of the perceived performance and financial performance of manufacturing firms and compared the two different methods in their research. The authors found that perceived performance measurement was a better representative of the financial figures. The authors concluded that the perceived performance measurement system is the best method to measure the firms’ performance as it helps to avoid a single respondent bias at the time of measuring the firm’s performance.

Many business units are started with full enthusiasm. However, these units are not able to survive in the market for a longer period and they break off their business very quickly. This study also tries to find the factors which are helping the manufacturing industries to perform successfully in this region from an operational perspective. The items used in the proposed study to evaluate the performance of the manufacturing industries are market share, sales growth, profit margin managed, return on assets and return on investment. This research model helps to specialize in assessing essential elements that influence the efficiency of the enterprise overall performance of manufacturing firms. This will permit the managerial workforce of manufacturing firms and policymakers to formulate and put into effect suitable and powerful operational techniques and to make rational and well-timed selections. The objective of the study is to segment the manufacturing industries by using Triangular Interval-Valued Fuzzy TOPSIS Method to factors determining the performance. For segmenting the manufacturing industries researchers used the Triangular Interval-valued Fuzzy TOPSIS method. This technique can be used to rank a large number of manufacturing industries based on multiple criteria. In this research work the researchers used the Triangular Interval-valued Fuzzy TOPSIS method to categories the manufacturing industries into three groups like “High Performing”, “Moderately Performing” and “Low Performing” based on the performance criteria.

Research methodology

This section describes elaborately the methodology part. The proposed research study is descriptive and it covers manufacturing industries. The researchers obtained both primary as well as secondary data collected from the top executives from the manufacturing industries situated in Union territory of Puducherry, India. The questionnaires contain two-segment; the first section contains demographic characteristics which includes Number of years in business (Company), Type of production system, Scale of industry, Kind of manufacturing, Type of product, Number of employees, Type of Industry and Location of the production plant of the respondents and second section covers five business performance measurement variable like Market Share, Sales Growth, Profit Margin, Return on Investment, and Return on Assets and it is in the form of 5 points Likert scale. The researchers used well-structured questionnaires to collect the data from 350 manufacturing industries. For obtaining they used a simple random sampling method to collect the data. To analyze the data, the researchers used well-sophisticated software packages like Excel, SPSS and LISREL 8.72. For finding out the result, the researchers applied Reliability, Communalities, Confirmatory Factor Analysis, Triangular Interval-Valued Fuzzy TOPSIS Method, Chi square and Correspondent Analysis to conclude the research work.

Analysis

The researchers describe the Confirmatory Factor Analysis, Triangular Interval-valued Fuzzy TOPSIS, Chi square, and Correspondence analysis to study the factor determining the performance of manufacturing industries in this section. For testing the reliability of the questionnaire the researchers used Cronbach’s Alpha test. The recommended minimum acceptable limit of the Cronbach’s Alpha test for the measurement is 0.60 [14]. The result of Cronbach’s Alpha value for business performance domains is 0.925. It far exceeds the required threshold limit of 0.6. Further, the estimated value of Cronbach’s Alpha value exceeds the “Alpha if Item Deleted” value ranges from 0.899 to 0.922. This signifies that all the items can be included in this study. After the reliability test, the researchers applied the communalities test to five business performance measurement variables. Higher communalities are better at the time of model formulation and the minimum threshold limit for establishing the commonality of the data is 0.5. All variables with a communality value of less than 0.5 should be removed. The results found from the communality value in respect of all the items far exceed the minimum desirable value of 0.5 and the range from 0.677 to 0.824. Hence all the five items are included for the study without dropping any of them. Based on the above test result the researchers moved to the next level and carry out confirmatory Factor Analysis.

Confirmatory factor analysis of performance (P)

The Confirmatory Factor Analysis (CFA) measurement model displays the relationship between the latent items and their observed measures. CFA displays the aptness with which the variables included under each factor fit into such a factor. The responses of the executives of manufacturing units about Performance were measured using the five indicators of P1, P2, P3, P4, and P5 as constituents of the Independent Measurement Model. Of these five items, the factor loadings in respect of the item Return On Assets (ROA) are less than 0.5. Hence this item is dropped from the study and CFA is run based on the remaining four items. CFA verifies the proposed factor structure. The results displayed in Table 1 reveals that the value of Chi square is 8.07, df is 2 and the p value is 0.01768 (which is < 0.05), indicating the precise fitness of the arrived model. The CFA takes care of confirming the designed factor arrangement. Results indicate that the remaining four-factor arrangement is highly significant. Hence, it can be concluded that all the four items included under this domain aptly fit into the said domain. Similarly, the reliability and validity of the model are confirmed by Construct Reliability (CR) being more than 0.70 and Average Variance Extracted (AVE) being more than 0.50. Good reliability and validity of the model signify the prevalence of satisfactory uni-dimensionality level.

The calculated values of GFI and RMSEA are 0.99 and 0.093. This satisfies the desired range of above 0.90 for GFI and 0.08–0.10 in respect of the RMSEA. Further, the values of AGFI as 0.94, CFI as 0.99 and NFI as 0.99 far exceed the desired threshold limit of 0.90. This signifies the mediocre fitness of the model. Hence, the results confirm the acceptability of the derived model.

The model for Performance (P) is shown in Fig. 1. It can be observed that the factor loadings well exceed the recommended threshold value of 0.50 and hence are significantly important. It can be inferred from the table that the manufacturing industries are giving high importance to Performance. Of the four items included in the factor of Performance indicators, the most influencing item is Sales growth (P2), followed by the other items of Market share (P1), Profit margin (P3) and finally Return on investment (P5).

With the endeavor of conducting an in-depth study on the Business Performance of the manufacturing industries, Triangular Interval-valued Fuzzy TOPSIS has been used to segregate the manufacturing industries into three segments namely Highly performing industries, Moderately performing industries and Low performing industries.

Triangular interval-valued fuzzy TOPSIS

Triangular Interval-valued Fuzzy TOPSIS has been performed to classify the manufacturing industries based on their Performance items. To understand the effectiveness of Performance items, the manufacturing industries have been segregated into related groups.

TOPSIS (Technique for Order Preference by Similarity to Ideal Solution) is a system propagated by [17]. This technique can be used to rank a large number of industries based on multiple criteria. The industries ranked are termed as “Alternatives” and the used parameter as items to rank the industries is known as “Attributes”. TOPSIS is a widely used Multi-Criteria Decision Making (MCDM) technique. The principle of TOPSIS is that the selected alternative should be as near as possible to the “Positive-Ideal Solution” and as far as possible from the “Negative-Ideal Solution”. Based on the proximity of the alternatives to the “Ideal Solution”, multi-criteria ranking index is constructed.

An algorithm was formulated by Jahanshahloo et al. [18] to use TOPSIS to interpret the interval data and arrive at meaningful decisions. TOPSIS and fuzzy TOPSIS have been utilized by Yang and Hung [33] to solve plant layout design problem. Both TOPSIS and fuzzy TOPSIS differ based on the rating approaches. Fuzzy TOPSIS assigns fuzzy numbers to the performance of the alternatives included for the study and the significance of the attributes used to analyze the performance of the alternatives. In the proposed study, the researchers have favored using the MCDM approach of TOPSIS because of the uncomplicated and programmable calculation process [5]. The researchers have attempted to solve the research problem using the MCDM approach of Triangular interval-valued fuzzy TOPSIS, which is a development over TOPSIS.

The MCDM case has been succinctly articulated as a matrix. The attributes used for the study are represented in columns, while the alternatives used for the study constitute the rows. Specifically, an MCDM problem with \( m \) alternatives \( A_{1} , \ldots ,A_{m} \) that are evaluated by \( n \) attributes \( C_{1} , \ldots ,C_{n} \) can be viewed as a geometric system with \( m \) points in \( n \)-dimensional space. An element \( x_{ij} \) of the matrix indicates the performance rating of the \( i_{{}} \) th alternative, \( A_{i} \) concerning the \( j \)th attribute, \( C_{j} \), as shown in Eq. (1):

A succinct description of the terms utilized in this research is provided in the forthcoming discussions:

Attributes Attributes \( \left( {C_{j} ,j = 1,2,3 \ldots n} \right) \) are the items used as criteria for assessing the performance of the manufacturing undertakings studied.

Alternatives Alternatives \( \left( {A_{i} ,i = 1,2,3 \ldots m} \right) \) are the 350 manufacturing undertakings of whose performance is to be assessed.

Attribute weights Weight values \( \left( {w_{j} } \right) \) each attribute used for this study has been assigned different weights depending upon their relative importance, based on Experts opinion \( W\left\{ {w_{j} /j} \right. = \begin{array}{*{20}c} {1,2, \ldots ,\left. n \right\}} \\ \end{array} . \)

The steps of TOPSIS methods can be summarized as follows:

-

Step 1.

Normalize the decision matrix \( X = \left( {x_{ij} } \right)_{m*n} \) using the equation below.

where \( r_{ij} \) is the normalized criteria rating.

-

Step 2.

Calculate the weighted normalized decision matrix \( V = \left( {v_{ij} } \right)_{m*n} \)

where \( w_{j} \) is the relative weight of the \( j \) th criterion, and \( \sum\nolimits_{j = 1}^{n} {w_{j} } = 1. \)

-

Step 3.

Determine the positive and negative ideal solutions.

where Ωb and Ωc are the sets of benefit criteria and cost criteria, respectively.

-

Step 4.

The separating distance of the alternatives from the positive and negative ideal solution is estimated.

-

Step 5.

The comparative nearness of each alternative to the ideal solution is estimated. The relative closeness of the alternative \( A_{i} \) concerning \( A* \) is defined as

-

Step 6.

Alternatives are ranked according to the comparative ideal solution. The biggest \( RC_{i} \), the better satisfying the alternative is \( A_{i} \). The alternative most close to the ideal solution can be the finest one.

Where \( {\text{RC}}_{i} \) indicates the ultimate performance score of each alternative. Those alternatives winning the highest performance score can be the most preferred alternative.

Interval-valued fuzzy sets (IVFS)

IVFS is a development over Fuzzy sets theory. Linguistic expressions presented by the usual Fuzzy sets do not yield adequate clarity. To tide over the limitations of Fuzzy sets theory, authors such as [9, 12, 20, 27, 30, 32] propagated the use of IVFS. They gave explanations about IVFS and assigned numbers for IVFS, which can be operational accordingly. Since then, IVFS has been used in all practical applications.

Using the concept of IVFS propagated by [12], an IVFS equation is formulated as \( \left( { - \infty , + \infty } \right) \) on is given by:

where \( \mu_{\text{A}}^{\text{L}} \left( x \right) \) represents the floor boundary concerning the degree of membership and \( \mu_{\text{A}}^{\text{U}} \left( x \right) \) represents the ceiling boundary.

Given the 2 IVFS numbers \( N_{x} = \left[ {N_{x}^{ - } ;N_{x}^{ + } } \right] \) and \( M_{y} = \left[ {M_{y}^{ - } ;M_{y}^{ + } } \right] \), according to [13, 16] the following equations may be derived:

Definition 1

If \( \in \left( { + , - , \times , \div } \right) \), then \( N.M(x.y) = \left[ {N_{x}^{ - } .M_{y}^{ - } ;N_{x}^{ + } .M_{y}^{ + } } \right] \)

Definition 2

The Normalized Euclidean distance between \( \tilde{N} \) and \( \tilde{M} \) is as follows:

Interval-valued fuzzy TOPSIS (IVFT)

The fuzzy method assigns Fuzzy numbers to denote the relative importance of each criterion. An effort has been made in the forthcoming section to extend the Fuzzy concept to the Fuzzy environment. This shall facilitate the searching for an effective solution to the group decision-maker problems.

Literature reveals that the TOPSIS technique has been utilized to group the manufacturing industries as “High Performing” and “Low Performing”. Hence, the researchers have utilized the MCDM approach to evaluate the performance of the manufacturing industries and segregate them into three categories based on their performance. The process adopted towards this endeavor is displayed in the following flow chart (see Fig. 2).

The values utilized for ranking the performance of the manufacturing industries and the comparative weights used for this purpose have been characterized using Fuzzy numbers ranging between 0 and 1. The membership value is expressed as an interval ranging between 0 and 1. The criteria values and criteria weights used in this study are regarded as linguistic variables. These variables are very useful while dealing with complex situations [34]. These linguistic variables have been transformed into triangular interval-valued fuzzy numbers and this transformation process is depicted in Tables 3 and 4.

Let \( \tilde{X} = \left[ {\tilde{x}_{ij} } \right]_{m*n} \) be a fuzzy decision matrix for a multi-criteria decision-making problem in which \( A_{1} ,A_{2} , \ldots ,A_{m} \) are \( m \) possible alternatives and \( C_{1} ,C_{2} , \ldots ,C_{n} \) are \( n \) criteria. So the performance of alternatives \( A_{i} \) concerning criterion \( C_{j} \) is denoted as \( \tilde{x}_{ij} \). As illustrated in Fig. 3, \( \tilde{x}_{ij} \) and \( \tilde{w}_{j} \) are expressed in triangular interval-valued fuzzy numbers.

Developing the TOPSIS for Triangular interval-valued fuzzy TOPSIS data is summarized as follows:

-

1.

Given \( \tilde{x}_{ij} = \left[ {\left( {a_{ij} ,a'_{ij} } \right); b_{ij} ; \left( {c'_{ij} ,c_{ij} } \right)} \right] \), the normalized performance rating as an extension to [6] can be calculated as:

Hence, the normalized matrix \( \tilde{R} = \left[ {\tilde{r}_{ij} } \right]_{m*n} \) can be obtained.

-

2.

Giving due consideration to the significance of each criteria, a weighted normalized fuzzy decision matrix may be developed as \( \tilde{V} = \left[ {\tilde{v}_{ij} } \right]_{m*n} \) where \( \tilde{v}_{ij} = \tilde{r}_{ij} \times \tilde{w}_{j} \) .

According to Definition 1, the multiply operator can be applied as:

-

3.

The positive and negative ideal solution may be explained as:

-

1.

Normalized Euclidean distance can be calculated using Definition 2 as follows:

where \( D^{ - } \left( {\tilde{N},\tilde{M}} \right) \) and \( D^{ + } \left( {\tilde{N},\tilde{M}} \right) \) are the primary and secondary distant measures, respectively. Thereby, the distance of each alternative from the ideal alternative \( \left[ {D_{i1}^{ + } .D_{i2}^{ + } } \right] \) can be currently calculated, where:

Likewise, the separation from the negative ideal solution is given by \( \left[ {D_{i1}^{ - } .D_{i2}^{ - } } \right] \), where:

Equations (13) and (14) have been used to assess the distance of the interval variables from the positive and negative ideal alternatives. By following this process, loss of information can be minimized using data values instead of crisp values.

4. The comparative proximity can be calculated as follows:

The Triangular Interval-valued fuzzy TOPSIS can be summed up as follows:

-

Normalize fuzzy decision matrix \( \tilde{X} = \left[ {\tilde{x}_{ij} } \right]_{m*n} \) by Eqs. (10) and (11).

-

The positive and negative ideal solution is assessed by Eq. (12).

-

Estimate the normalized Euclidean proximity by Eqs. (13) and (14).

-

Using a pair of separations assess the proximity of each alternative to the fuzzy scores (15).

-

Ascertain the comparative proximity by Eq. (16).

-

Alternatives may be ranked based on their comparative proximity.

-

More proximate the alternative to the ideal solution \( {\text{RC}}_{i} \), the more pleasant the alternative \( A_{i} \) will be. Closer the alternative to the ideal solution, the better it is.

-

\( {\text{RC}}_{i} \) Where indicates the ultimate TOPSIS score. A higher score indicates that the alternative is performing better than the others.

The application of the extended method in solving problems

In this study, the responses of the executives of manufacturing industries about Performance were measured using the four items namely P1, P2, P3, and P5. The 350 manufacturing industries are segmented into three groups namely highly performing group, moderately performing group and low performing group.

This is based on the following four criteria:

-

(a)

Market share (C1).

-

(b)

Sales growth (C2).

-

(c)

Profit margin (C3) and

-

(d)

Return on investment(C4).

The response of the executives of the manufacturing industries is considered as the evaluation of the industries. The significance of each of the chosen criteria is depicted in Tables 3 and 4.

The proposed issue will be unraveled utilizing the interval-valued fuzzy TOPSIS. Table 5 depicts the interval-valued fuzzy TOPSIS decision matrix and weights. The choice framework is additionally standardized by utilizing Eq. (10).

Table 6 depicts the normalized decision matrix.

Table 7 shows the weighted normalized matrix. Euclidean separation from the perfect and negative perfect options are determined to utilize (13) and (14) recipes, separately. The outcomes have been delineated in Table 8. As demonstrated, the distance from ideal and negative ideal alternatives are determined as an interval.

Applying Eq. (15), the comparative proximity of the interval is gotten and the outcomes are portrayed in Table 9.

Ultimately, Table 10 contains the ranks assigned each of the alternative using Eq. (16).

The ranking of the 350 manufacturing industries is displayed in Table 10. The Performance variables are in the form of metrics. So the Performance items are converted into category form by using the Triangular Interval-Valued Fuzzy TOPSIS Method. By applying the Triangular Interval-Valued Fuzzy TOPSIS Method the researchers segmented the manufacturing industries into three groups namely highly performing group, moderately performing group and low performing group. To find out the factors determining the performance of manufacturing industries the researchers applied Chi square and correspondence analysis.

Associations between performance segments and demographic variables

It is important to study the demographic characteristics influencing the Performance of the three segments. To identify the variables that have an impact on the performance segment, it is necessary to find out the variables that have an association with it. The Chi square test is used for this purpose. Table 11 provides Chi square values and their significance for the association between Performance segment and demographic characteristics. The included demographic characteristics are the Number of years in business (Company), Type of production system, Scale of industry, Kind of manufacturing, Type of product, Number of employees, Type of Industry and Location of the production plant of the respondents.

Table 11, it is evident that the demographic characteristics other than the three variables, Type of production system, Type of product and Industry type do not have a significant association with the performance segment of the manufacturing industries. The relationships between the five remaining demographic characteristics are significantly associated with the performance segment. For those significantly associated variables, researchers applied correspondence analysis, it is a graphical representation and helps to check the association among the variables.

Length of existence of the manufacturing industries and performance segment

To analyze the association between the length of existence of the manufacturing industries and the performance segment, the researchers performed Chi square and correspondence analysis.

It can be inferred from the Table 12 that almost one-third of the manufacturing industries which are in existence for a period of fewer than 5 years, 11–15 years and 16–20 years come under the “Low performing” group and almost half of the manufacturing industries which are in existence for a period of 5–10 years come under the “Moderately performing”. It can further be noted that half of the manufacturing industries which are in existence for a period of 21–25 years and 25 years and above come under the “Highly performing”.

Figure 4 portrays the results of Correspondence Analysis to explore the association between the length of existence of the manufacturing industries and their performance segment. The figure displays that those manufacturing industries with a length of existence of fewer than 5 years and 16–20 years are closely associated with the “Low performing” group, while those units which are engaged in business for a period of 5–10 years and 11–15 years are associated with the “Moderately performing” group. Those manufacturing industries engaged in business for a period of 21–25 years and above 25 years are closely associated with the “Highly performing” group.

Association between scale of industry and performance segment

To explore the association between the demographic variable of Scale of the industry to which the manufacturing industries belong and their performance segment, Chi square, and correspondence analysis have been performed. The cross-tabulation between Scale of industry and Performance segment of the manufacturing industries categorized under the three group have been displayed in Table 13.

It can be observed from the Table 13 that majority of the Small scale manufacturing industries (37.6%) come under the “Low performing” group, while a simple majority of the Medium scale industries (36.2%) and a shade above six-tenth of the large scale industries (61.1%) come under the “Highly performing” group.

Figure 5 portrays the results of Correspondence Analysis conducted to explore the association between the nature of the industry of the manufacturing industries and their performance segment. The figure explicates that the manufacturing industries falling under the Small Scale Industries category are closely associated with the “Low performing” group, while the industries falling under the medium scale industries are associated with the “Moderately performing” group. Large scale industries are closely associated with the “Highly performing” group.

Association between kind of manufacturing industry and performance segment

To assess the association between the demographic variable of kind of manufacturing industry and performance segment, Chi square, and correspondence analysis has been performed. The cross-tabulation between kinds of manufacturing industry and performance of the three segments is presented in the Table 14.

It can be observed from the Table 14 that majority of the manufacturing concerns engaged in Process and both process and product (38.9% and 41.9%, respectively) come under the “Highly performing” group, while a simple majority of the manufacturing industries engaged in Discrete or Product (38.6%) come under the “Low performing” group.

Figure 6 displays the results of Correspondence Analysis performed to assess the association between the manufacturing industries falling under different kinds of industries and their performance segment. The figure displays that the manufacturing enterprises falling under the discrete (product) industries are closely associated with the “Low performing” group, while the enterprises falling under the Process industries are closely associated with the “Highly performing” group.

Association between the Number of Employees in the Enterprise and Performance Segment

To analyze the association between the demographic variable of Number of employees working in the manufacturing industries and performance segment, Chi square, and correspondence analysis has been performed. The cross-tabulation between the Number of employees working in the manufacturing industries and the performance segment is presented in the following table.

It can be observed from the Table 15 that majority of the manufacturing industries employing less than 50 (44.6%) come under the “Low performing” group, while the majority of the industries employing 101–250 (42.5%) come under the “Moderately performing” group, and the majority of the industries employing 51–100, 251–500 and 501 and above (37.4%, 52.9%, and 48.9%, respectively) come under the “Highly performing” group.

Figure 7 portrays the results of Correspondence Analysis conducted to explore the association between the number of employees employed by the manufacturing industries and their Performance. The figure depicts that manufacturing industries with less than 50 employees are closely associated with the “Low performing” group, while the industries with 101–250 employees are closely associated with the “Moderately performing” group and remaining all the other categories 51–100, 251–500 and 501 and above are closely associated with the “Highly performing” group.

Association between plant location and performance segment

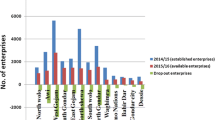

To analyze the association between the demographic variable of Plant Location and performance segment, Chi square, and correspondence analysis have been performed. The cross-tabulation between plant location and performance of the manufacturing industries categorized into three segments is depicted in the Table 16.

It can be observed from the Table 16 that majority of the manufacturing industries with a production plant located in Pondicherry (38.7%) come under the “Highly performing”, while the majority of the manufacturing industries with plant located at Karaikal (67.4%) and Yanam (40%) come under the “Low performing” group, and the majority of the manufacturing industries with plant located at Mahe (60%) come under the “Moderately performing” group.

Figure 8 portrays the results of Correspondence Analysis conducted to explore the association between the manufacturing industries with different plant locations and their performance segment. The figure elucidates that the manufacturing industries with plant located at Puducherry are closely associated with the “Highly performing” group, while those with plant location at Mahe are closely associated with the “Moderately performing” group and those manufacturing industries with plant location at Karaikal and Yanam are closely associated with “Low performing” group.

Conclusion

The production businesses are giving excessive importance to business performance. The researchers used the CFA version to show the aptness with which the variables blanketed beneath every factor suit into this sort of thing. And the used Triangular Interval-valued Fuzzy TOPSIS method to segment the respondents into three groups like “Highly Performing”, “Moderately Performing” and “Low Performing”. After that researchers used segmented performance groups and demographic characteristics to identify the factors determining the performance of manufacturing industries. The researchers found that the demographics characteristics Number of years in business (Company), Scale of industry, Kind of manufacturing, Number of employees and location of the production plant of the respondents are significantly associated with the performance segments of the manufacturing industries. This research has analyzed the business performance of the manufacturing industries at a single point in time. However, these factors are constantly changing in nature, and a longitudinal follow up research should be conducted to identify these changes and re-examine the variation of the relationships. This study has been conducted involving manufacturing industries operating in Puducherry at small, medium and large scales. However, the study on industries operating with identical scales covering all over India will yield better results which may facilitate a better conclusion. The models developed to correspond to the manufacturing enterprises belonging to different industries. However, studies may be conducted on enterprises of a specific industry and this will yield precise results.

References

Akintimehin OO, Eniola AA, Alabi OJ, Eluyela DF, Okere W, Ozordi E (2019) Social capital and its effect on business performance in the Nigeria informal sector. Heliyon 5(7):e02024

Amorim G, Hatakeyama K, Rojas-Lema X (2018) Implantation of total productive maintenance: a case study in the manufacturing industry, New global perspectives on industrial engineering and management. Springer, Cham, pp 259–267

Bharadwaj AS (2000) A resource-based perspective on information technology capability and firm performance: an empirical investigation. MIS Q 24(1):169–196

Çankaya SY, Sezen B (2019) Effects of green supply chain management practices on sustainability performance. J Manuf Technol Manag 30(1):98–121

Chakraborty S (2011) Applications of the MOORA method for decision making in manufacturing environment. Int J Adv Manuf Technol 54(9–12):1155–1166

Chen CT (2000) Extensions of the TOPSIS for group decision-making under fuzzy environment. Fuzzy Sets Syst 114(1):1–9

Chen PP, Chong PP, Chen JCH (2000) Small business management: an IT based approach. J Comput Inf Syst 41(2):40–47

Clark JT (1982) Selling top management understanding the financial impact of manufacturing systems. In: American Production and Inventory Control Society Conference Proceedings, Falls Church, VA, 1982

Cornelis G, Deschrijver G, Kerre EE (2006) Advances and challenges in interval-valued fuzzy logic. Fuzzy Sets Syst 157(5):622–627

Droge C, Vickery S, Markland RE (1994) Sources and outcomes of competitive advantage: an exploratory study in the furniture industry. Deci 25(5/6):669–689

Ganeshkumar C, Prabhu M, Nabaz NA (2019) Business analytics and supply chain performance: partial least squares-structural equation modeling (PLS-SEM) Approach. Int J Manag Bus Res 9(1):91–96

Gorzalczany MB (1987) A method of inference in approximate reasoning based on interval-valued fuzzy sets. Fuzzy Sets Syst 21(1):1–17

Grzegorzewski P (2004) Distances between intuitionist fuzzy sets and/or interval valued fuzzy sets based on the Hausdorff metric. Fuzzy Set Syst 148(2):319–328

Hair JF, Anderson R, Tatham R, Black W (1998) Multivariate data analysis, 5th edn. Prentice-Hall, Upper Saddle River

Hill CWL, Jones GR (1992) Instructor’s resource manual with test questions: strategic management theory, an integrated approach. Houghton Mifflin Company, Boston

Hong DH, Lee S (2002) Some algebraic properties and a distance measure for interval valued fuzzy numbers. Inf Sci 148(1–4):1–10

Hwang CL, Yoon K (1981) Multiple attribute decision making-methods and applications. Springer-Verlag, Heidelberg

Jahanshahloo GR, Lotfi FH, Izadikhah M (2006) Extension of the TOPSIS method for decision-making problems with fuzzy data. Appl Math Comput 181(2):1544–1551

Kamble S, Gunasekaran A, Dhone NC (2020) Industry 40 and lean manufacturing practices for sustainable organisational performance in Indian manufacturing companies. Int J Prod Res 58(5):1319–1337

Karnik NN, Mendel JM (2001) Operations on type-2 fuzzy sets. Fuzzy Sets Syst 122(2):327–348

Ketokivi M, Schroeder R (2004) Manufacturing practices, strategic fit and performance a routine-based view. Int J Oper Prod Manag 24(2):171–191

Mad Lazim H, Ramayah T, Ahmad TN (2008) Total productive maintenance and performance: A Malaysian SME experience. Int Rev Bus Res Papers 4(4):237–250

Nobel MA (1995) Manufacturing strategy: testing the cumulative model in a multiple country context. Decis Sci 26(5):693–718

Pagell M, Krause DR (2004) Re-Exploring the relationship between flexibility and the external environment. J Oper Manag 21(6):629–649

Petrillo F, De Felice, Zomparelli F (2019) “Performance measurement for world-class manufacturing: a model for the Italian automotive industry. Total Q Manag Bus Excell 30(7–8):908–935

Phusavat K, Anussornnitisarn P, Helo P, Dwight R (2009) Performance measurement: roles and challenges. Indu Manag Data Syst 109(5):646–664

Pourhejazy P, Sarkis J, Zhu Q (2019) A fuzzy-based decision aid method for product deletion of fast moving consumer goods. Expert Syst Appl 119:272–288

Prabhu M, Nambirajan T, Abdullah NN (2020) Analytical review on competitive priorities for operations under manufacturing firms. J Ind Eng Manag 13(1):38–55

Santhanam R, Hartono E (2003) Issues in linking information technology capability to firm performance. MIS Q 27(1):125–153

Turksen IB, Bilgic T (1996) Interval-valued strict preference with Zadeh triples. Fuzzy Sets Syst 78(2):183–195

Wade M, Hulland J (2004) The Resource-Based View and Information Systems Research: review, Extension, and Suggestions for Future Research. MIS Q 28(1):107–142

Wang G, Li X (1998) The applications of interval-valued fuzzy numbers and interval-distribution numbers. Fuzzy Sets Syst 98(3):331–335

Yang T, Hung CC (2007) Multiple-attribute decision making methods for plant layout design problem. Robot Comput Integr Manuf 23(1):126–137

Zadeh L (1975) The concept of a linguistic variable and its application to approximate reasoning-I. Inf Sci 8(3):199–249

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author declares no potential conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Prabhu, M., Abdullah, N.N., Ahmed, R.R. et al. Segmenting the manufacturing industries and measuring the performance: using interval-valued triangular fuzzy TOPSIS method. Complex Intell. Syst. 6, 591–606 (2020). https://doi.org/10.1007/s40747-020-00157-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40747-020-00157-0