Abstract

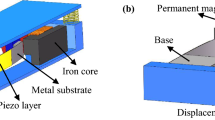

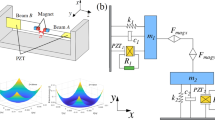

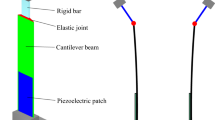

In order to realize the energy harvesting structure working for an external perturbation or ultralow-frequency excitation, a continuous structure with adjustable nonlinearity is proposed and analyzed. The novel energy harvesting structure is consisted of a piezoelectric elastic beam and two pairs of magnets. Different from normal assembly of magnets in the same direction of the vibration motion, two pairs of magnets are assembled vertically to the vibration direction to induce adjustable nonlinear restoring force similar as the pre-deformed elastic components in so-called quasi-zero-stiffness system. With the model of magnets, the interaction energy and interaction force are obtained. Considering the the piezoelectric cantilever beam, it can realize a multi-stable vibration structure. The zero equilibrium is stable and the interaction energy there is very high, while there are two symmetry stable equilibriums with very low interaction energy. Thus, for small-amplitude and ultralow-frequency excitations from natural phenomenon such as dropping raining, the structure can have large-amplitude vibration with adjustable output frequency. At last, we realize the proposed vibration energy harvester by designing the structural according to the theoretical analysis. The structure of this study has potentially remarkable applications in intelligent and sustainable power generation.

Similar content being viewed by others

Abbreviations

- L :

-

Then length of cantilever beam

- A :

-

Length of magnet on mass in x-direction

- B :

-

Length of magnet on mass in y-direction

- C :

-

Thickness of magnet on mass

- a :

-

Length of magnet on base in x-direction

- b :

-

Length of magnet on base in y-direction

- c :

-

Thickness of magnet on base

- d :

-

Distances in one-pair of magnets

- J :

-

Magnetizations

- μ :

-

Permeability of intervening medium

References

Babayo, A. A., Anisi, M. H., & Ali, I. (2017). A Review on energy management schemes in energy harvesting wireless sensor networks. Renewable and Sustainable Energy Reviews, 76, 1176–1184.

Zi, Y., Lin, L., Wang, J., Wang, S., Chen, J., Fan, X., et al. (2015). Triboelectric–pyroelectric–piezoelectric hybrid cell for high-efficiency energy-harvesting and self-powered sensing. Advanced Materials, 27(14), 2340–2347.

Allane, D., Vera, G. A., Duroc, Y., Touhami, R., & Tedjini, S. (2016). Harmonic power harvesting system for passive RFID sensor tags. IEEE Transactions on Microwave Theory, 64(7), 2347–2356.

Le, C. P., Halvorsen, E., Søråsen, O., & Yeatman, E. M. (2012). Microscale electrostatic energy harvester using internal impacts. Journal of Intelligent Material Systems and Structures, 23(13), 1409–1421.

Khaligh, A., Zeng, P., & Zheng, C. (2010). Kinetic energy harvesting using piezoelectric and electromagnetic technologies—state of the art. IEEE Transactions on Industrial Electronics, 57(3), 850–860.

Kim, H. S., Kim, J. H., & Kim, J. (2011). A review of piezoelectric energy harvesting based on vibration. International Journal of Precision Engineering and Manufacturing, 12(6), 1129–1141.

Mori, K., Horibe, T., Ishikawa, S., Shindo, Y., & Narita, F. (2015). Characteristics of vibration energy harvesting using giant magnetostrictive cantilevers with resonant tuning. Smart Materials and Structures, 24, 12.

Fan, F. R., Tang, W., & Wang, Z. L. (2016). Flexible Nanogenerators for Energy Harvesting and Self-Powered Electronics. Advanced Materials, 28(22), 4283–4305.

Wei, C., & Jing, X. (2017). A comprehensive review on vibration energy harvesting: modelling and realization. Renewable and Sustainable Energy Reviews, 74, 1–18.

Noh, S., Lee, H., & Choi, B. (2013). A study on the acoustic energy harvesting with Helmholtz resonator and piezoelectric cantilevers. International Journal of Precision Engineering and Manufacturing, 14, 1629–1635.

Kim, H. S., Kim, J. H., & Kim, J. (2011). A review of piezoelectric energy harvesting based on vibration. International Journal of Precision Engineering and Manufacturing, 12, 1129–1141.

Kim, C., & Shin, J. W. (2013). Topology optimization of piezoelectric materials and application to the cantilever beams for vibration energy harvesting. International Journal of Precision Engineering and Manufacturing, 14, 1925–1931.

Abas, Z., Kim, H. S., Zhai, L., & Kim, J. (2015). Experimental study of vibrational energy harvesting using Electro-Active paper. International Journal of Precision Engineering and Manufacturing, 16, 1187–1193.

Pillai, M. A., & Deenadayalan, E. (2014). A review of acoustic energy harvesting. International Journal of Precision Engineering and Manufacturing, 15, 949965.

Truitt, A., & Mahmoodi, S. N. (2013). A review on active wind energy harvesting designs. International Journal of Precision Engineering and Manufacturing, 14, 1667–1675.

Priya, S., & Inman, D. J. (2009). Energy harvesting technologies. New York: Springer.

Li, H., Tian, C., & Deng, Z. D. (2014). Energy harvesting from low frequency applications using piezoelectric materials”. Applied Physics Reviews, 1, 4.

Alamiana, R., Shafaghata, R., Hosseinia, S. S., & Zainalib, A. (2017). Wave energy potential along the southern coast of the Caspian Sea. International Journal of Marine Energy, 19, 221–234.

Xin, Y., Li, X., Tian, H., Guo, C., Qian, C., Wang, S., et al. (2016). Shoes-equipped piezoelectric transducer for energy harvesting: a brief review. Ferroelectrics, 493(1), 12–24.

Donelan, J. M., Li, Q., Naing, V., Hoffer, J. A., Webe, D. J., & Kuo, A. D. (2008). Biomechanical energy harvesting: generating electricity during walking with minimal user effort. Science, 319, 807.

Xie, X. D., & Wang, Q. (2015). Energy harvesting from a vehicle suspension system. Energy, 86, 385–392.

Tianchen, Y., Jian, Y., Ruigang, S., & Xiaowei, L. (2014). Vibration energy harvesting system for railroad safety based on running vehicles. Smart Materials and Structures, 23, 12.

Sazonov, E., Li, H., Curry, D., & Pillay, P. (2009). Self-powered sensors for monitoring of highway bridges. IEEE Sensors Journal, 9(11), 1422–1429.

Xie, X. D., Wang, Q., & Wang, S. J. (2015). Energy harvesting from high-rise buildings by a piezoelectric harvester device. Energy, 93, 1345–1352.

Jeon, J., Hong, J., Lee, S. J., & Chung, S. K. (2019). Acoustically excited oscillating bubble on a flexible structure and its energy-harvesting capability. International Journal of Precision Engineering and Manufacturing, 5, 1–7.

Park, J. H., Lim, T. W., Kim, S. D., & Park, S. H. (2016). Design and experimental verification of flexible plate-type piezoelectric vibrator for energy harvesting system. International Journal of Precision Engineering and Manufacturing, 3, 253–259.

Kim, J. E., Kim, H., Yoon, H., et al. (2015). An Energy conversion model for cantilevered piezoelectric vibration energy harvesters using only measurable parameters”. International Journal of Precision Engineering and Manufacturing, 2, 51–57.

Usharani, R., & Uma, G. Umapathy. (2016). Design of high output broadband piezoelectric energy harvester with double tapered cavity beam. International Journal of Precision Engineering and Manufacturing, 3, 343–351.

Ahmed, A., Hassan, I., Hedaya, M., El-Yazid, T. A., Zu, J., & Wang, Z. L. (2017). Farms of triboelectric nanogenerators for harvesting wind energy: a potential approach towards green energy. Nano Energy, 36, 21–29.

Ilyas, M. A., & Swingler, J. (2015). Piezoelectric energy harvesting from raindrop impacts. Energy, 90, 796–806.

Leadenham, S., & Erturk, A. (2014). M-shaped asymmetric nonlinear oscillator for broadband vibration energy harvesting: harmonic balance analysis and experimental validation. Journal of Sound and Vibration, 333(23), 6209–6223.

Fan, K., Tan, Q., Zhang, Y., et al. (2018). A monostable piezoelectric energy harvester for broadband low-level excitations. Applied Physics Letters, 112(12), 123901.

Chen, L., Jiang, W., Panyam, M., & Daqaq, M. (2016). A broadband internally resonant vibratory energy harvester. Journal of Vibration and Acoustics, 138, 6.

Wang, F., Sun, X., & Xu, J. (2018). A novel energy harvesting device for ultralow frequency excitation. Energy, 151, 250–260.

Xueping, X., Chunlong, Z., Qinkai, H., & Fulei, C. (2018). Hybrid energy harvesting from mechanical vibrations and magnetic field. Applied Physics Letters, 113, 1.

Zhou, S., Cao, J., Inman, D. J., Lin, J., Liu, S., & Wang, Z. (2014). Broadband tristable energy harvester: modeling and experiment verification. Applied Energy, 133, 33–39.

Zheng, W., Yan, B., Ma, H., Wang, R., Jia, J., & Zhang, L. (2019). Tuning of natural frequency with electromagnetic shunt mass. Smart Materials and Structures, 28, 025026.

Nguyen, M. S., Yoon, Y. J., Kwon, O., & Kim, P. (2017). Lowering the potential barrier of a bistable energy harvester with mechanically rectified motion of an auxiliary magnet oscillator. Applied Physics Letters, 111, 25.

Kim, P., Nguyen, M. S., Kwon, O., Kim, Y. J., & Yoon, Y. J. (2016). Phase-dependent dynamic potential of magnetically coupled two-degree-of-freedom bistable energy harvester. Scientific Reports, 6, 34411.

Akoun, G., & Yonnet, J. P. (1984). 3D analytical calculation of the forces exerted between two cuboidal magnets. IEEE Transactions on Magnetics, 20, 1962–1964.

Allag, H., & Yonnet, J. P. (2011). 3-D Analytical calculation of the torque and force exerted between two cuboidal magnets. IEEE Transactions on Magnetics, 109, 199–216.

Acknowledgements

The authors would like to gratefully acknowledge the support from the National Natural Science Foundation of China under Grant no. 11772229 and no. 11602141, Shanghai Sailing Program no. 16YF1408000, Natural Science Foundation of Shanghai No. 16ZR1423600.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sun, X., Wang, F. & Xu, J. Nonlinear Piezoelectric Structure for Ultralow-frequency Band Vibration Energy Harvesting with Magnetic Interaction. Int. J. of Precis. Eng. and Manuf.-Green Tech. 6, 671–679 (2019). https://doi.org/10.1007/s40684-019-00117-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40684-019-00117-1