Abstract

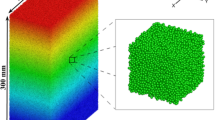

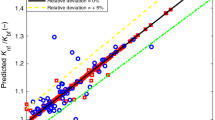

Artificial neural network (ANN), a machine learning technique, is employed to predict the effective thermal conductivity of granular assemblies in the presence of a stagnant gas. ANN is trained with the help of estimated thermal conductivities calculated through resistor network (RN) model. RN model considers the effect of the presence of stagnant gas and the gas pressure (Smoluchowski effect) for the calculation of effective thermal conductivity. Granular assemblies are generated and compacted through discrete element method (DEM). The ANN is trained to predict the effective thermal conductivity of a granular assembly for a set of measurable experimental parameters (stress and packing fraction) without requiring the knowledge of microstructural details (coordination numbers and overlaps) of the assembly. The predicted effective thermal conductivity values through ANN are in good agreement with the experimental results. Estimation of effective thermal conductivity through the trained ANN is much faster (few seconds compared to few hours required for DEM together with RN approach) with very good accuracy.

Similar content being viewed by others

References

Cundall PA, Strack ODL (1979) A discrete numerical model for granular assemblies. Géotechnique 29(1):47–65

Gan Y, Kamlah M (2010) Discrete element modelling of pebble beds: with application to uniaxial compression tests of ceramic breeder pebble beds. J Mech Phys Solids 58(2):129–144

Annabattula RK, Gan Y, Kamlah M (2012) Mechanics of binary and polydisperse spherical pebble assembly. Fusion Eng Des 87(5):853–858

Desu RK, Gan Y, Kamlah M, Annabattula RK (2016) Mechanics of binary crushable granular assembly through discrete element method. Nucl Mater Energy 9:237–241

Kovalev OB, Gusarov AV (2017) Modeling of granular packed beds, their statistical analyses and evaluation of effective thermal conductivity. Int J Therm Sci 114:327–341

Bagi K (2003) Statistical analysis of contact force components in random granular assemblies. Granul Matter 5(1):45–54

Peeketi AR, Moscardini M, Vijayan A, Gan Y, Kamlah M, Annabattula RK (2018) Effective thermal conductivity of a compacted pebble bed in a stagnant gaseous environment: an analytical approach together with dem. Fusion Eng Des 130:80–88

Singhal SC (2000) Advances in solid oxide fuel cell technology. Solid State Ion 135(1):305–313

Farid MM, Khudhair AM, Razack SAK, Al-Hallaj S (2004) A review on phase change energy storage: materials and applications. Energy Convers Manag 45(9–10):1597–1615

Ying A, Reimann J, Boccaccini L, Enoeda M, Kamlah M, Knitter R, Gan Y, van der Laan JG, Magielsen L, Di Maio PA, DellOrco G, Annabattula RK, Van Lew JT, Tanigawa H, van Til S (2012) Status of ceramic breeder pebble bed thermo-mechanics R&D and impact on breeder material mechanical strength. Fusion Eng Des 87(7):1130–1137

Yun TS, Evans TM (2010) Three-dimensional random network model for thermal conductivity in particulate materials. Comput Geotech 37:991–998

Moscardini M, Gan Y, Pupeschi S, Kamlah M (2018) Discrete element method for effective thermal conductivity of packed pebbles accounting for the Smoluchowski effect. Fusion Eng Des 127:192–201

Dai W, Pupeschi S, Hanaor D, Gan Y (2017) Influence of gas pressure on the effective thermal conductivity of ceramic breeder pebble beds. Fusion Eng Des 118:45–51

Panchal M, Kang C, Ying A, Chaudhuri P (2018) Experimental measurement and numerical modeling of the effective thermal conductivity of lithium metatitanate pebble bed. Fusion Eng Des 127:34–39

Zehner P, Schlünder EU (1970) Wärmeleitfähigkeit von schüttungen bei mäßigen temperaturen. Chemie Ingenieur Technik 42(14):933–941

Bauer R, Schlunder EU (1978) Part I: effective radial thermal conductivity of packings in gas flow. Part II: thermal conductivity of the packing fraction without gas flow. Int Chem Eng 18:181–204

Weidenfeld G, Weiss Y, Kalman H (2004) A theoretical model for effective thermal conductivity (etc) of particulate beds under compression. Granul Matter 6(2–3):121–129

Martis J, Annabattula RK (2017) A semi-analytical model for the effective thermal conductivity of a multi-component polydisperse granular bed. Granul Matter 19(4):84

Springer GS (1971) Heat transfer in rarefied gases. Adv Heat Transf 7:163–218

Reimann J, Hermsmeyer S (2002) Thermal conductivity of compressed ceramic breeder pebble beds. Fusion Eng Des 61:345–351

Batchelor GK, O’Brien RW (1977) Thermal or electrical conduction through a granular material. Proc R Soc Lond Ser A Math Phys Sci 355:313–333

Kanuparthi S, Subbarayan G, Siegmund T, Sammakia B (2008) An efficient network model for determining the effective thermal conductivity of particulate thermal interface materials. IEEE Trans Compon Packag Technol 31(3):611–621

Kaganer MG (1969) Thermal insulation in cryogenic engineering. Israel Program for Scientific Translations

Wakao N, Kagei S (1982) Heat and mass transfer in packed beds, vol 1. Taylor & Francis, London

Goodman FO (1980) Thermal accommodation coefficients. J Phys Chem 84(12):1431–1445

Gupta AK, Guntuku SC, Desu RK, Balu A (2015) Optimisation of turning parameters by integrating genetic algorithm with support vector regression and artificial neural networks. Int J Adv Manuf Technol 77(1–4):331–339

Prasad KS, Desu RK, Lade J, Singh SK, Gupta AK (2013) Finite element modeling and prediction of thickness strains of deep drawing using ANN and LS-Dyna for ASS304. AIP Conf Proc 1567(1):402–405

Gupta AK (2010) Predictive modelling of turning operations using response surface methodology, artificial neural networks and support vector regression. Int J Prod Res 48(3):763–778

Li J, Cheng J, Shi j, Huang F (2012) Brief introduction of back propagation (bp) neural network algorithm and its improvement. In: Advances in computer science and information engineering. Springer, pp 553–558

MATLAB. Neural network toolbox, the mathworks, Natick, MA, USA, R2015b

Löbbecke B, Knitter R, Rohde M, Reimann J (2009) Thermal conductivity of sintered lithium orthosilicate compacts. J Nucl Mater 386:1068–1070

Saito S, Tsuchiya K, Kawamura H, Terai T, Tanaka S (1998) Density dependence on thermal properties of Li\(_2\)TiO\(_3\) pellets. J Nucl Mater 253(1–3):213–218

Liu YY, Tam SW (1985) Thermal conductivities for sintered and sphere-pac Li\(_2\)O and \(\gamma \)-LiAlO\(_2\) solid breeders with and without irradiation effects. Fusion Sci Technol 7(3):399–410

Lide DR (2006) CRC handbook of chemistry and physics. CRC Press, Boca Raton

The engineering toolbox. http://www.engineeringtoolbox.com/dry-air-properties-d_973.html. Accessed 01 June 2018

Pupeschi S, Knitter R, Kamlah M (2017) Effective thermal conductivity of advanced ceramic breeder pebble beds. Fusion Eng Des 116:73–80

Hofer D, Kamlah M (2005) Drucker-Prager-Cap creep modelling of pebble beds in fusion blankets. Fusion Eng Des 73(2–4):105–117

Han LH, Elliott JA, Bentham AC, Mills A, Amidon GE, Hancock BC (2008) A modified Drucker-Prager Cap model for die compaction simulation of pharmaceutical powders. Int J Solids Struct 45(10):3088–3106

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Desu, R.K., Peeketi, A.R. & Annabattula, R.K. Artificial neural network-based prediction of effective thermal conductivity of a granular bed in a gaseous environment. Comp. Part. Mech. 6, 503–514 (2019). https://doi.org/10.1007/s40571-019-00228-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40571-019-00228-1