Abstract

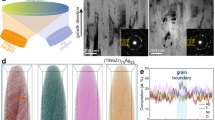

Refractory high/medium entropy nitrides (HENs/MENs) exhibit comprehensive application prospects as protective films on mechanical parts, particularly those subjected to sliding contacts at elevated temperatures. In this study, a new MEN system TiNbWN, forming a single fcc solution, is designed and its wear performance at temperatures ranging from 25 to 750 °C is explored. The wear mechanisms can be rationalized by examining the subsurface microstructural evolutions using the transmission electron microscopy as well as calculating the phase diagrams and interfacial adhesion behavior employing calculation of phase diagram (CALPHAD) and density functional theory (DFT). To be specific, increased wear losses occur in a temperature range of 25–600 °C, being predominantly caused by the thermally-induced hardness degradation; whereas at the ultimate temperature (750 °C), the wear loss is refrained due to the formation of nanocrystalline oxides (WnO3n−2, TiO2, and γTiOx), as synergistically revealed by microscopy and CALPHAD, which not only enhance the mechanical properties of the pristine nitride film, but also act as solid lubricants, reducing the interfacial adhesion. Thus, our work delineates the role of the in situ formed nanocrystalline oxides in the wear mechanism transition of TiNbWN thin films, which could shed light on the high-temperature wear behavior of refractory HEN/MEN films.

Article PDF

Similar content being viewed by others

Reference

Yeh J W, Chen S K, Lin S J, Gan J Y, Chin T S, Shun T T, Tsau C H, Chang S Y. Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv Eng Mater 6(5): 299–303 (2004)

George E P, Raabe D, Ritchie R O. High-entropy alloys. Nat Rev Mater 4(8): 515–534 (2019)

Cantor B, Chang I T H, Knight P, Vincent A J B. Microstructural development in equiatomic multicomponent alloys. Mater Sci Eng A 375–377: 213–218 (2004)

Zhang Y. Materials design of high-entropy materials. In: High-Entropy Materials: A Brief Introduction. Singapore: Springer Singapore, 2019: 35–63.

Oses C, Toher C, Curtarolo S. High-entropy ceramics. Nat Rev Mater 5(4): 295–309 (2020)

Moon J, Park J M, Bae J W, Do H S, Lee B J, Kim H S. A new strategy for designing immiscible medium-entropy alloys with excellent tensile properties. Acta Mater 193: 71–82 (2020)

Lewin E. Multi-component and high-entropy nitride coatings—A promising field in need of a novel approach. J Appl Phys 127(16): 160901 (2020)

Shu R, Paschalidou E M, Rao S G, Lu J, Greczynski G, Lewin E, Nyholm L, le Febvrier A, Eklund P. Microstructure and mechanical, electrical, and electrochemical properties of sputter-deposited multicomponent (TiNbZrTa)Nx coatings. Surf Coat Technol 389: 125651 (2020)

Shu R, Paschalidou E M, Rao S G, Bakhit B, Boyd R, Moro M V, Primetzhofer D, Greczynski G, Nyholm L, le Febvrier A, et al. Effect of nitrogen content on microstructure and corrosion resistance of sputter-deposited multicomponent (TiNbZrTa)Nx films. Surf Coat Technol 404: 126485 (2020)

Baran Ö. Manetron Sıçratma Yöntemiyle Kaplanmış TiNbN ve TiVN Filmlerin Mekanik ve Tribolojik Özelliklerinin İncelenmesi. Gümüşhane Üniversitesi Fen Bilimleri Enstitüsü Dergisi 7(2): 181–191 (2017) (in Turkish)

Serro A P, Completo C, Colaço R, dos Santos F, da Silva C L, Cabral J M S, Araújo H, Pires E, Saramago B. A comparative study of titanium nitrides, TiN, TiNbN and TiCN, as coatings for biomedical applications. Surf Coat Technol 203(24): 3701–3707 (2009)

Zhou S, Liu W G, Liu H, Cai C L. Structural and electrical properties of Ti-W-N thin films deposited by reactive RF sputtering. Phys Procedia 18: 66–72 (2011)

Shaginyan L R, Mišina M, Zemek J, Musil J, Regent F, Britun V F. Composition, structure, microhardness and residual stress of W-Ti-N films deposited by reactive magnetron sputtering. Thin Solid Films 408(1–2): 136–147 (2002)

Kuchuk A V, Kladko V P, Lytvyn O S, Piotrowska A, Minikayev R A, Ratajczak R. Relationship between condition of deposition and properties of W-Ti-N thin films prepared by reactive magnetron sputtering. Adv Eng Mater 8(3): 209–212 (2006)

Cavaleiro A, Trindade B, Vieira M T. Influence of Ti addition on the properties of W—Ti—C/N sputtered films. Surf Coat Technol 174–175: 68–75 (2003)

Jalali R, Parhizkar M, Bidadi H, Naghshara H, Eshraghi M J. Characterization of nano-crystalline Ti-W-N thin films for diffusion barrier application: A structural, microstructural, morphological and mechanical study. Appl Phys A 124(12): 810 (2018)

Jalali R, Parhizkar M, Bidadi H, Naghshara H. Correlation between optical, structural and microstructural properties of Ti-W-N thin films. Ceram Int 46(5): 6454–6461 (2020)

Kitamika Y, Shingu H, Tanigawa S, Hasegawa H. Mechanical properties and oxidation resistance of Ti1−xWxN coatings. J Surf Finish Soc Jpn 69(11): 517–520 (2018)

Lou M, Chen X, Xu K, Deng Z X, Chen L L, Lv J, Chang K K, Wang L P. Temperature-induced wear transition in ceramic-metal composites. Acta Mater 205: 116545 (2021)

Meng Y G, Xu J, Jin Z M, Prakash B, Hu Y Z. A review of recent advances in tribology. Friction 8(2): 221–300 (2020)

Chen X, Han Z. A low-to-high friction transition in gradient nano-grained Cu and Cu-Ag alloys. Friction 9(6): 1558–1567 (2021)

Lou M, White D R, Banerji A, Alpas A T. Dry and lubricated friction behaviour of thermal spray low carbon steel coatings: Effect of oxidational wear. Wear 432–433: 102921 (2019)

Lou M, Alpas A T. High temperature wear mechanisms in thermally oxidized titanium alloys for engine valve applications. Wear 426–427: 443–453 (2019)

Yang R, Ma W, Duan C J, Li S, Wang T M, Wang Q H. Self-lubrication of tribologically-induced oxidation during dry reciprocating sliding of aged Ti-Ni51.5 at% alloy. Friction 9(5): 1038–1049 (2021)

Fink M. Wear oxidation—A new component of wear. T Am Soc Steel Treating 18:1026–1034 (1930)

Stott F H. The role of oxidation in the wear of alloys. Tribol Int 31(1–3): 61–71 (1998)

Cui X H, Wang S Q, Wang F, Chen K M. Research on oxidation wear mechanism of the cast steels. Wear 265(3–4): 468–476 (2008)

Childs T H C. The sliding wear mechanisms of metals, mainly steels. Tribol Int 13(6): 285–293 (1980)

Dohda K, Boher C, Rezai-Aria F, Mahayotsanun N. Tribology in metal forming at elevated temperatures. Friction 3(1): 1–27 (2015)

Dong X, Jahanmir S. Wear transition diagram for silicon nitride. Wear 165(2): 169–180 (1993)

Zhou Z, Rainforth W M, Luo Q, Hovsepian P E, Ojeda J J, Romero-Gonzalez M E. Wear and friction of TiAlN/VN coatings against Al2O3 in air at room and elevated temperatures. Acta Mater 58(8): 2912–2925 (2010)

Javdošňák D, Musil J, Soukup Z, Haviar S, Čerstvý R, Houska J. Tribological properties and oxidation resistance of tungsten and tungsten nitride films at temperatures up to 500 °C. Tribol Int 132: 211–220 (2019)

Moghaddam P V, Prakash B, Vuorinen E, Fallqvist M, Andersson J M, Hardell J. High temperature tribology of TiAlN PVD coating sliding against 316L stainless steel and carbide-free bainitic steel. Tribol Int 159: 106847 (2021)

Magnéli A. Structures of the ReO3-type with recurrent dislocations of atoms: “Homologous series” of molybdenum and tungsten oxides. Acta Crystallogr 6: 495–500 (1953)

Woydt M, Skopp A, Dörfel I, Witke K. Wear engineering oxides/anti-wear oxides. Wear 218(1): 84–95 (1998)

Migas D B, Shaposhnikov V L, Borisenko V E. Tungsten oxides. II. The metallic nature of Magnéli phases. J Appl Phys 108(9): 093714 (2010)

Liu Y L, Wang Z X, Sun Q C, Yin B, Cheng J, Zhu S Y, Yang J, Qiao Z H, Liu W M. Tribological behavior and wear mechanism of pure WC at wide range temperature from 25 to 800 °C in vacuum and air environment. Int J Refract Met Hard Mater 71: 160–166 (2018)

Lugscheider E, Knotek O, Bobzin K, Bärwulf S. Tribological properties, phase generation and high temperature phase stability of tungsten- and vanadium-oxides deposited by reactive MSIP-PVD process for innovative lubrication applications. Surf Coat Technol 133–134: 362–368 (2000)

Suszko T, Gulbiński W, Jagielski J. The role of surface oxidation in friction processes on molybdenum nitride thin films. Surf Coat Technol 194(2–3): 319–324 (2005)

Oliver W C, Pharr G M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J Mater Res 7(6): 1564–1583 (1992)

Hohenberg P, Kohn W. Inhomogeneous electron gas. Phys Rev 136(3B): B864–B871 (1964)

Kresse G, Hafner J. Ab initio molecular-dynamics simulation of the liquid-metal-amorphous-semiconductor transition in germanium. Phys Rev B 49(20): 14251–14269 (1994)

Kresse G, Joubert D. From ultrasoft pseudopotentials to the projector augmented-wave method. Phys Rev B 59(3): 1758–1775 (1999)

Blöchl P E. Projector augmented-wave method. Phys Rev B 50(24): 17953–17979 (1994)

Predel F. Phase Equilibria, Crystallographic and Thermodynamic Data of Binary Alloys. Heidelberg (Germany): Springer Berlin Heidelberg, 2016.

Huang W M. Thermodynamic assessment of the Nb—N system. Metall Mater Trans A 27(11): 3591–3600 (1996)

Miao K F, Wang J, Zhao Q, Wang K W, Wen M, Zhang K. Water-based lubrication of niobium nitride. Friction 10(6): 842–853 (2022)

Lin J L, Moore J J, Mishra B, Pinkas M, Sproul W D. The structure and mechanical and tribological properties of TiBCN nanocomposite coatings. Acta Mater 58(5): 1554–1564 (2010)

Leyland A, Matthews A. On the significance of the H/E ratio in wear control: A nanocomposite coating approach to optimised tribological behaviour. Wear 246(1–2): 1–11 (2000)

Archard J F, Hirst W. The wear of metals under unlubricated conditions. Proc Roy Soc A Math Phy Sci 236(1206): 397–410 (1956)

Hutchings I, Shipway P. Tribology: Friction and Wear of Engineering Materials, 2nd edn. Oxford (UK): Butterworth-Heinemann, 2017.

Hampl M, Schmid-Fetzer R. Thermodynamic description of the Ti-O system. Int J Mater Res 106(5): 439–453 (2015)

Erb U, Palumbo G, McCrea J L. The processing of bulk nanocrystaline metals and alloys by electrodeposition. In: Nanostructured Metals and Alloys: Processing, microstructure, mechanical properties and applications, Whang S H, Ed. Cambridge (UK): Woodhead Publishing, 2011: 118–151.

Li Y, Song K F. Study on manufacture process, micro-hardness and Hall-Petch relation of pure rutile phase TiO2 MAO coating. Appl Mech Mater 738–739: 175–179 (2015)

Bahador A, Umeda J, Hamzah E, Yusof F, Li X C, Kondoh K. Synergistic strengthening mechanisms of copper matrix composites with TiO2 nanoparticles. Mater Sci Eng A 772: 138797 (2020)

Chen J, Lu D Y, Zhang W H, Xie F Y, Zhou J, Gong L, Liu X, Deng S Z, Xu N S. Synthesis and Raman spectroscopic study of W20O58 nanowires. J Phys D Appl Phys 41(11): 115305 (2008)

Sun L, Li Z, Su R, Wang Y L, Li Z L, Du B S, Sun Y, Guan P F, Besenbacher F, Yu M. Phase-transition induced conversion into a photothermal material: Quasi-metallic WO2.9 nanorods for solar water evaporation and anticancer photothermal therapy. Angew Chem Int Ed 57(33): 10666–10671 (2018)

Pirker L, Višić B, Škapin S D, Dražić G, KovaČ J, Remškar M. Multi-stoichiometric quasi-two-dimensional WnO3n−1 tungsten oxides. Nanoscale 12(28): 15102–15114 (2020)

Wriedt H A. The O-W (oxygen-tungsten) system. Bull Alloy Phase Diagr 10(4): 368–384 (1989)

Kutschej K, Mayrhofer P H, Kathrein M, Polcik P, Mitterer C. A new low-friction concept for Ti1−xAlxN based coatings in high-temperature applications. Surf Coat Technol 188–189: 358–363 (2004)

Reeswinkel T, Music D, Schneider J M. Coulomb-potential-dependent decohesion of magnéli phases. J Phys Condens Matter 22(29): 292203 (2010)

Lugscheider E, Bärwulf S, Barimani C. Properties of tungsten and vanadium oxides deposited by MSIP-PVD process for self-lubricating applications. Surf Coat Technol 120–121: 458–464 (1999)

Gassner G, Mayrhofer P H, Kutschej K, Mitterer C, Kathrein M. Magnéli phase formation of PVD Mo-N and W-N coatings. Surf Coat Technol 201(6): 3335–3341 (2006)

Zhang J, Li M J, Feng Z C, Chen J, Li C. UV Raman spectroscopic study on TiO2. I. Phase transformation at the surface and in the bulk. J Phys Chem B 110(2): 927–935 (2006)

Polcar T, Parreira N M G, Cavaleiro A. Structural and tribological characterization of tungsten nitride coatings at elevated temperature. Wear 265(3–4): 319–326 (2008)

Xu K, Chang K K, Yu M, Zhou D P, Du Y, Wang L P. Design of novel NiSiAlY alloys in marine salt-spray environment: Part II. Al-Ni-Si-Y thermodynamic dataset. J Mater Sci Technol 89: 186–198 (2021)

Xu K, Chang K K, Zhou X B, Chen L L, Liu J W, Deng Z X, Huang F, Huang Q. Thermodynamic descriptions of the light rare-earth elements in silicon carbide ceramics. J Am Ceram Soc 103(6): 3812–3825 (2020)

Liu S D, Chang K K, Music D, Chen X, Mráz S, Bogdanovski D, Hans M, Primetzhofer D, Schneider J M. Stress-dependent prediction of metastable phase formation for magnetron-sputtered V1−xAlxN and Ti1−xAlxN thin films. Acta Mater 196: 313–324 (2020)

Wang C, Dai Y B, Gao H Y, Ruan X M, Wang J, Sun B D. Surface properties of titanium nitride: A first-principles study. Solid State Commun 150(29–30): 1370–1374 (2010)

Riedl H, Zálešák J, Arndt M, Polcik P, Holec D, Mayrhofer P H. Ab initio studies on the adsorption and implantation of Al and Fe to nitride materials. J Appl Phys 118(12): 125306 (2015)

Zhao L H, Tian F H, Wang X B, Zhao W W, Fu A P, Shen Y Y, Chen S G, Yu S Q. Mechanism of CO adsorption on hexagonal WO3 (001) surface for gas sensing: A DFT study. Comput Mater Sci 79: 691–697 (2013)

Saadi L, Lambert-Mauriat C, Oison V, Ouali H, Hayn R. Mechanism of NOx sensing on WO3 surface: First principle calculations. Appl Surf Sci 293: 76–79 (2014)

Oison V, Saadi L, Lambert-Mauriat C, Hayn R. Mechanism of CO and O3 sensing on WO3 surfaces: First principle study. Sens Actuat B Chem 160(1): 505–510 (2011)

Hurtado-Aular O, Vidal A B, Sierraalta A, Añez R. Periodic DFT study of water adsorption on m-WO3(001), m-WO3(100), h-WO3(001) and h-WO3(100). Role of hydroxyl groups on the stability of polar hexagonal surfaces. Surf Sci 694: 121558 (2020)

Albanese E, di Valentin C, Pacchioni G. H2O adsorption on WO3 and WO3−x(001) surfaces. ACS Appl Mater Interfaces 9(27): 23212–23221 (2017)

Sorescu D C, Rusu C N, Yates J T. Adsorption of NO on the TiO2(110) surface: An experimental and theoretical study. J Phys Chem B 104(18): 4408–4417 (2000)

Sorescu D C, Yates J T. Adsorption of CO on the TiO2(110) surface: A theoretical study. J Phys Chem B 102(23): 4556–4565 (1998)

Klyukin K, Alexandrov V. CO2 adsorption and reactivity on rutile TiO2(110) in water: An ab initio molecular dynamics study. J Phys Chem C 121(19): 10476–10483 (2017)

Wang C, Dai Y B, Gao H Y, Ruan X M, Wang J, Sun B D. Ab initio molecular dynamics study of Fe adsorption on TiN (001) surface. Mater Trans 51(11): 2005–2008 (2010)

Kang Q X, Wang G F, Liu Q, Sui X C, Liu Y K, Chen Y Q, Luo S Y, Li Z L. Investigation for oxidation mechanism of CrN: A combination of DFT and ab initio molecular dynamics study. J Alloys Compd 885: 160940 (2021)

Guo F Y, Wang J C, Du Y, Wang J, Shang S L, Li S L, Chen L. First-principles study of adsorption and diffusion of oxygen on surfaces of TiN, ZrN and HfN. Appl Surf Sci 452: 457–462 (2018)

Music D, Schneider J M. Ab initio study of Ti0.5Al0.5N(001)—residual and environmental gas interactions. New J Phys 15(7): 073004 (2013)

Sanyal S, Waghmare U V, Ruud J A. Adsorption of water on TiN(100), (110) and (111) surfaces: A first-principles study. Appl Surf Sci 257(15): 6462–6467 (2011)

Acknowledgements

Financial support from the National Natural Science Foundation of China (52142501 and 52101026), the National Key R&D Program of China (2018YFA0703400), Natural Science Foundation of Zhejiang Province (LQ20E010004), China Postdoctoral Science Foundation (2021M693250), Ningbo 3315 Innovation Team (2019A-18-C), CAS PIFI program (2022VEA0005), and CAS Pioneer Hundred Talents Program are greatly acknowledged.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Declaration of competing interest

The authors have no competing interests to declare that are relevant to the content of this article.

Leilei CHEN. He received his bachelor degree in 2016 from Wuhan University of Science and Technology, Wuhan, China. In 2019, he obtained his M.E. degree in mechanical engineering from Dalian University of Technology, Dalian, China. His is currently a Ph.D. student in the Key Laboratory for Precision and Non-Traditional Machining Technology of Ministry of Education at Dalian University of Technology. His research interests include friction performances and wear mechanisms of the physical vapour deposition (PVD) nitride films.

Zhenyu ZHANG. He received his B.E. degree in mechanical engineering in 2000 from Hebei Institute of Science and Technology, Tangshan, China. In 2003, he received M.E. degree in mechanical engineering from Hebei University of Technology, Tianjin, China. After that, he obtained his Ph.D. degree in 2005 in solid mechanics from Tianjin University, Tianjin, China. His current position is a professor in mechanical engineering at Dalian University of Technology, Dalian, China. His research interests focus on precision and ultra-precision machining technologies, and high performance manufacturing.

Keke CHANG. He received his bachelor and master degree from Central South University, Changsha, China, in 2008 and 2010, respectively, and Ph.D. degree from RWTH Aachen University, Germany, in 2013. He is now a professor at Ningbo Institute of Materials Technology and Engineering, Chinese Academy of Sciences, Ningbo, China. His research interest is theoretical design of coatings, surfaces, and interfaces for serving in harsh environments.

Rights and permissions

This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made.

The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Chen, L., Zhang, Z., Lou, M. et al. High-temperature wear mechanisms of TiNbWN films: Role of nanocrystalline oxides formation. Friction 11, 460–472 (2023). https://doi.org/10.1007/s40544-022-0621-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40544-022-0621-x