Abstract

The present work aims to investigate the heat transfer and pressure drop of Alumina/oil nanofluid flow in a miniaturized square channel in the presence of strong DC electric fields. The high voltage was applied using a thin wire on top of the channel. The bottom of the channel was used as both a ground electrode and a heated surface. Results showed that increasing particle concentration caused heat transfer augmentation for all Reynolds numbers. Applying a strong electric potential of 15.51 kV resulted in considerable heat transfer enhancement of 52% for the nanofluid with 0.3% volume fraction, at the Reynolds number of 7. This considerable enhancement can be attributed to the formation of the ion injection-based secondary flows and motion of the particles. The generated secondary flow disrupts the boundary layer and increases the heat absorption from the heated surface. The experiments were confined to the volume fraction of 0.3% since the rapid agglomeration of particles occurred on electrode and walls at the volume fraction of 0.5%.

Similar content being viewed by others

Abbreviations

- \(A\) :

-

Heat transfer area [m2]

- \(c_{p}\) :

-

Heat capacity [J/kg k]

- \(D_{h}\) :

-

Hydraulic diameter [m]

- \(E\) :

-

Electric field [V/m]

- \(f\) :

-

Friction factor [-]

- \(f_{{\text{e}}}\) :

-

Electrical body force [N/m3]

- \(f_{s}\) :

-

Friction factor (without heat transfer enhancement) [−]

- \(h\) :

-

Convection heat transfer coefficient [W/m2 K]

- \(\overline{h}\) :

-

Average convection heat transfer coefficient [W/m2 K]

- \(j\) :

-

Colburn factor [−]

- \(j_{s}\) :

-

Colburn factor (without heat transfer enhancement) [−]

- \(k\) :

-

Thermal conductivity [W/m K]

- \(\dot{m}\) :

-

Mass flow rate [kg/s]

- \(Nu\) :

-

Nusselt number [−]

- \(Po\) :

-

Poiseuille Number [−]

- \(Pr\) :

-

Prandtl number [−]

- \(\dot{Q}\) :

-

Heat transfer rate [W]

- \(\dot{q}\) :

-

Heat flux [W/m2]

- \(Re\) :

-

Reynolds number [−]

- \(St\) :

-

Stanton number [−]

- \(T\) :

-

Temperature [°C]

- \(u\) :

-

Velocity in x-direction [m/s]

- \(V\) :

-

Voltage [V]

- \(v\) :

-

Velocity in y-direction [m/s]

- \(w\) :

-

Velocity in z-direction

- \({\Delta }P\) :

-

Pressure drop [pa]

- \(\alpha\) :

-

Thermal diffusivity [m2/s]

- \(\varepsilon\) :

-

Electrical permittivity coefficient [−]

- \(\eta\) :

-

Efficiency index [−]

- \(\mu\) :

-

Dynamic viscosity [Pa s]

- \(\rho\) :

-

Density [kg/m3]

- \(\rho_{e}\) :

-

Space charge density [c/m3

- \({\text{o}}\) :

-

Zero voltage condition

- b:

-

Bulk

- in:

-

Inlet

- out:

-

Outlet

References

Gholizadeh T, Vajdi M, Rostamzadeh H (2019) A new biogas-fueled bi-evaporator electricity/cooling cogeneration system: exergoeconomic optimization. Energy Convers Manag 196:1193–1207. https://doi.org/10.1016/j.enconman.2019.06.053

Gholizadeh T, Vajdi M, Rostamzadeh H (2020) Exergoeconomic optimization of a new trigeneration system driven by biogas for power, cooling, and freshwater production. Energy Convers Manag 205:112417. https://doi.org/10.1016/j.enconman.2019.112417

Yekani F, AbdiAghdam S, SadeghMoghanlo E (2019) Experimental study of the performance and exhaust gas emissions response of a spark ignition engine to Adding Natural Gas to Gasoline in CR=11. Int J Ind Math 11:307–317

Moghanlou FS, Khorrami AS, Esmaeilzadeh E, Aminfar H (2014) Experimental study on electrohydrodynamically induced heat transfer enhancement in a minichannel. Exp Therm Fluid Sci 59:24–31. https://doi.org/10.1016/j.expthermflusci.2014.07.019

Aminfar H, Mohammadpourfard M, Maroofiazar R (2014) Experimental study on the effect of magnetic field on critical heat flux of ferrofluid flow boiling in a vertical annulus. Exp Therm Fluid Sci 58:156–169. https://doi.org/10.1016/j.expthermflusci.2014.06.023

Noorzadeh S, Sadegh Moghanlou F, Vajdi M, Ataei M (2020) Thermal conductivity, viscosity and heat transfer process in nanofluids: a critical review. J Compos Compd https://doi.org/10.29252/jcc.2.4.1

Webb RL, Kim N-H (2005) Principles enhanced heat transfer. CRC Press, Boca Raton

Dehghani T, Sadegh Moghanlou F, Vajdi M, Shahedi Asl M, Shokouhimehr M, Mohammadi M (2020) Mixing enhancement through a micromixer using topology optimization. Chem Eng Res Des 161:187–196. https://doi.org/10.1016/j.cherd.2020.07.008

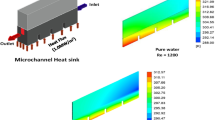

Fattahi M, Vaferi K, Vajdi M, Sadegh Moghanlou F, SabahiNamini A, ShahediAsl M (2020) Aluminum nitride as an alternative ceramic for fabrication of microchannel heat exchangers: a numerical study. Ceram Int. https://doi.org/10.1016/j.ceramint.2020.01.195

Heat Transfer and Fluid Flow in Minichannels and Microchannels, Elsevier, 2006. doi:https://doi.org/10.1016/B978-0-08-044527-4.X5000-2.

Vajdi M, SadeghMoghanlou F, Ranjbarpour Niari E, Shahedi Asl M, Shokouhimehr M (2020) Heat transfer and pressure drop in a ZrB2 microchannel heat sink: a numerical approach. Ceram Int. https://doi.org/10.1016/j.ceramint.2019.09.146

Wang C-C, Jeng Y-R, Chien J-J, Chang Y-J (2004) Frictional performance of highly viscous fluid in minichannels. Appl Therm Eng 24:2243–2250. https://doi.org/10.1016/j.applthermaleng.2004.01.003

Arshad W, Ali HM (2017) Experimental investigation of heat transfer and pressure drop in a straight minichannel heat sink using TiO 2 nanofluid. Int J Heat Mass Transf 110:248–256. https://doi.org/10.1016/j.ijheatmasstransfer.2017.03.032

Sakkaki M, Sadegh Moghanlou F, Parvizi S, Baghbanijavid H, Babapoor A, Shahedi Asl M (2020) Phase change materials as quenching media for heat treatment of 42CrMo4 steels. J Cent South Univ.

Maxwell JC (1954) A treatise on electricity and magnetism. Clarendon Press, New York

Elsheikh AH, Sharshir SW, Mostafa ME, Essa FA, Ahmed Ali MK (2018) Applications of nanofluids in solar energy: a review of recent advances. Renew Sustain Energy Rev 82:3483–3502. https://doi.org/10.1016/j.rser.2017.10.108

Das SK, Choi SUS, Yu W, Pradeep T (2007) Nanofluids. Wiley, Hoboken, NJ

Choi SUS, Zhang ZG, Yu W, Lockwood FE, Grulke EA (2001) Anomalous thermal conductivity enhancement in nanotube suspensions. Appl Phys Lett 79:2252–2254. https://doi.org/10.1063/1.1408272

Ali M, Zeitoun O, Almotairi S, Al-Ansary H (2013) The effect of alumina-water nanofluid on natural convection heat transfer inside vertical circular enclosures heated from above. Heat Transf Eng 34:1289–1299. https://doi.org/10.1080/01457632.2013.793115

Ali M, Zeitoun O, Almotairi S (2013) Natural convection heat transfer inside vertical circular enclosure filled with water-based Al2O3 nanofluids. Int J Therm Sci 63:115–124. https://doi.org/10.1016/j.ijthermalsci.2012.07.008

Lee S, Choi SU-S, Li S, Eastman JA (1999) Measuring thermal conductivity of fluids containing oxide nanoparticles. J Heat Transfer 121:280–289. https://doi.org/10.1115/1.2825978

Wang X, Xu X, Choi SUS (1999) Thermal conductivity of nanoparticle - fluid mixture. J Thermophys Heat Transf 13:474–480. https://doi.org/10.2514/2.6486

Anoop KB, Sundararajan T, Das SK (2009) Effect of particle size on the convective heat transfer in nanofluid in the developing region. Int J Heat Mass Transf 52:2189–2195. https://doi.org/10.1016/j.ijheatmasstransfer.2007.11.063

Pak BC, Cho YI (1998) Hydrodynamic and heat transfer study of dispersed fluids with submicron metallic oxide particles. Exp Heat Transf 11:151–170. https://doi.org/10.1080/08916159808946559

Li Q, Xuan Y (2002) Convective heat transfer and flow characteristics of Cu-water nanofluid. Sci China Ser E Technolgical Sci 45:408–416. https://doi.org/10.1360/02ye9047

Duangthongsuk W, Wongwises S (2017) An experimental investigation on the heat transfer and pressure drop characteristics of nanofluid flowing in microchannel heat sink with multiple zigzag flow channel structures. Exp Therm Fluid Sci 87:30–39. https://doi.org/10.1016/j.expthermflusci.2017.04.013

W.Y. Lai, P.E. Phelan, S. Vinod, R. Prasher, Convective heat transfer for water-based alumina nanofluids in a single 1.02-mm tube. In: 2008 11th intersociety conference on thermal and thermomechanical phenomena in electronic systems, IEEE, 2008: pp. 970–978. doi:https://doi.org/10.1109/ITHERM.2008.4544372.

Zeitoun O, Ali M (2012) Nanofluid impingement jet heat transfer. Nanoscale Res Lett 7:139. https://doi.org/10.1186/1556-276X-7-139

Zeitoun O, Ali M, Al-Ansary H (2013) The effect of particle concentration on cooling of a circular horizontal surface using nanofluid jets. Nanoscale Microscale Thermophys Eng 17:154–171. https://doi.org/10.1080/15567265.2012.749963

Jung J-Y, Oh H-S, Kwak H-Y (2009) Forced convective heat transfer of nanofluids in microchannels. Int J Heat Mass Transf 52:466–472. https://doi.org/10.1016/j.ijheatmasstransfer.2008.03.033

Sadegh Moghanlou F, Noorzadeh S, Ataei M, Vajdi M, Shahedi Asl M, Esmaeilzadeh E (2020) Experimental investigation of heat transfer and pressure drop in a minichannel heat sink using Al2O3 and TiO2–water nanofluids. J Braz Soc Mech Sci Eng 42:315. https://doi.org/10.1007/s40430-020-02403-5

Ataei M, Sadegh Moghanlou F, Noorzadeh S, Vajdi M, Shahedi Asl M (2020) Heat transfer and pressure drop in a minichannel heat sink using hybrid Al2O3/TiO2–water nanofluid, Heat Mass Transf

Bakthavatchalam B, Habib K, Saidur R, Saha BB, Irshad K (2020) Comprehensive study on nanofluid and ionanofluid for heat transfer enhancement: A review on current and future perspective. J Mol Liq 305:112787. https://doi.org/10.1016/j.molliq.2020.112787

Hajati Z, Sadegh Moghanlou F, Vajdi M, Razavi E, Matin S (2020) Fluid structure interaction of blood flow around a vein valve, BioImpacts

Vajdi M, Sadegh Moghanlou F, Sharifianjazi F, Shahedi Asl M, Shokouhimehr M (2020) A review on the Comsol Multiphysics studies of heat transfer in advanced ceramics. J Compos Compd 2(2020):35–44. https://doi.org/10.29252/jcc.2.1.5

Nourdanesh N, Hossainpour S, Esmaeilzadeh E (2019) Experimental investigation of heat transfer enhancement in an open-channel flow with dielectric fluid using electrohydrodynamic conduction pumps concept. Appl Therm Eng 157:113711. https://doi.org/10.1016/j.applthermaleng.2019.04.121

Allen PHG, Karayiannis TG (1995) Electrohydrodynamic enhancement of heat transfer and fluid flow. Heat Recover Syst CHP 15:389–423. https://doi.org/10.1016/0890-4332(95)90050-0

Seyed-Yagoobi J, Bryan JE (1999) Enhancement of heat transfer and mass transport in single-phase and two-phase flows with electrohydrodynamics. Adv Heat Transf. https://doi.org/10.1016/S0065-2717(08)70304-6

Jones TB (1979) electrohydrodynamically enhanced heat transfer in liquids—a review. Adv Heat Transf 14:107–148

Paschkewitz JS, Pratt DM (2000) The influence of fluid properties on electrohydrodynamic heat transfer enhancement in liquids under viscous and electrically dominated flow conditions. Exp Therm Fluid Sci 21:187–197. https://doi.org/10.1016/S0894-1777(00)00002-9

Jafari M, Farrokhi N, Esmaeilzadeh E (2020) Effects of working temperature and fluid physical properties on heat transfer enhancement in conduction pumping: An experimental study. Int J Therm Sci 156:106471. https://doi.org/10.1016/j.ijthermalsci.2020.106471

Grassi W, Testi D, Saputelli M (2005) Heat transfer enhancement in a vertical annulus by electrophoretic forces acting on a dielectric liquid. Int J Therm Sci 44:1072–1077. https://doi.org/10.1016/j.ijthermalsci.2005.03.017

Liu L, Chen K, Xiang N, Ni Z (2019) Dielectrophoretic manipulation of nanomaterials: a review. Electrophoresis 40:873–889. https://doi.org/10.1002/elps.201800342

Zhang Y, Chen X (2020) Dielectrophoretic microfluidic device for separation of red blood cells and platelets: a model-based study. J Brazilian Soc Mech Sci Eng 42:89. https://doi.org/10.1007/s40430-020-2169-x

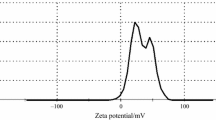

Sarojini KGK, Manoj SV, Singh PK, Pradeep T, Das SK (2013) Electrical conductivity of ceramic and metallic nanofluids. Coll Surf A Physicochem Eng Asp 417:39–46. https://doi.org/10.1016/j.colsurfa.2012.10.010

Ganguly S, Sikdar S, Basu S (2009) Experimental investigation of the effective electrical conductivity of aluminum oxide nanofluids. Powder Technol 196:326–330. https://doi.org/10.1016/j.powtec.2009.08.010

Asadzadeh F, Nasr Esfahany M, Etesami N (2012) Natural convective heat transfer of Fe3O4/ethylene glycol nanofluid in electric field. Int J Therm Sci 62:114–119. https://doi.org/10.1016/j.ijthermalsci.2011.11.010

Kordzadeh A, De Zanche N (2016) Permittivity measurement of liquids, powders, and suspensions using a parallel-plate cell. Concepts Magn Reson Part B Magn Reson Eng 46:19–24. https://doi.org/10.1002/cmr.b.21318

Rea U, McKrell T, Hu L, Buongiorno J (2009) Laminar convective heat transfer and viscous pressure loss of alumina–water and zirconia–water nanofluids. Int J Heat Mass Transf 52:2042–2048. https://doi.org/10.1016/j.ijheatmasstransfer.2008.10.025

Xuan Y, Roetzel W (2000) Conceptions for heat transfer correlation of nanofluids. Int J Heat Mass Transf 43:3701–3707. https://doi.org/10.1016/S0017-9310(99)00369-5

Corcione M (2011) Empirical correlating equations for predicting the effective thermal conductivity and dynamic viscosity of nanofluids. Energy Convers Manag 52:789–793. https://doi.org/10.1016/j.enconman.2010.06.072

Hamilton RL, Crosser OK (1962) Thermal conductivity of heterogeneous two-component systems. Ind Eng Chem Fundam 1:187–191. https://doi.org/10.1021/i160003a005

Kline SJ, McClintock FA (1953) Describing uncertainties in single-sample experiments. Mech Eng 75:3–8

O’Connor PDT (1990) Experimentation and uncertainty analysis for engineers , H. W. Coleman and W. G. Steele, Wiley, 1989. Number of pages: 205. Price: £35.50. Qual Reliab Eng Int 6:231–231. https://doi.org/10.1002/qre.4680060315

Moffat RJ (1988) Describing the uncertainties in experimental results. Exp Therm Fluid Sci 1:3–17. https://doi.org/10.1016/0894-1777(88)90043-X

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Ahmad Arabkoohsar.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Appendix 1

Appendix 1

Uncertainty for the parameters involved in the analysis is calculated and summarized in Table 3. Calculations for parameters’ uncertainties are as follow:

-

1. Reynolds number, Re

$$\frac{{X_{Re} }}{Re} = \sqrt {\left( {2\frac{{X_{m} }}{m}} \right)^{2} + \left( {( - 1)\frac{{X_{t} }}{t}} \right)^{2} + \left( {( - 1)\frac{{X_{\mu } }}{\mu }} \right)^{2} } = \sqrt {(0.00066)^{2} + (0.0038)^{2} + (0.01)^{2} } = 0.010719$$(14) -

2. Heat flux, qʺ

$$\frac{{X_{{q^{{\prime \prime }} }} }}{{q^{{\prime \prime }} }} = \sqrt {\left( {\frac{{X_{V} }}{V}} \right)^{2} + \left( {\frac{{X_{I} }}{I}} \right)^{2} + \left( {( - 1)\frac{{X_{L} }}{L}} \right)^{2} } = \sqrt {(0.000098)^{2} + (0.042915)^{2} + (0.000023)^{2} } = 0.0429$$(15) -

3. Convection heat transfer coefficient, h

$$\frac{{X_{{\text{h}}} }}{h} = \sqrt {\left( {\frac{{X_{{q^{{\prime \prime }} }} }}{{q^{{\prime \prime }} }}} \right)^{2} + \left( {( - 1)\frac{{X_{{T_{w} - T_{\infty } }} }}{{T_{w} - T_{\infty } }}} \right)^{2} } = \sqrt {(0.0429)^{2} + (0.0031)^{2} } = 0.04301$$(16)

Rights and permissions

About this article

Cite this article

Sadegh Moghanlou, F., Shams Khorrami, A., Esmaeilzadeh, E. et al. Effect of strong electric field on heat transfer enhancement in a mini channel containing Al2O3/oil nanofluid. J Braz. Soc. Mech. Sci. Eng. 43, 149 (2021). https://doi.org/10.1007/s40430-021-02869-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-021-02869-x