Abstract

The objective of this paper is to recognize the probabilistic distribution of crack growth and stress intensity factor for surface crack. A model with surface crack is subjected to arbitrary constant-amplitude loads. The model is analysed using probabilistic S-version finite element model (ProbS-FEM). In order to decide the probabilistic distribution, Latin hypercube sampling is embedded with ProbS-FEM. Simulation model is compared with experimental specimens. The specimens are prepared and investigated for fatigue testing. Good agreement between predictions, experiments, and previous numerical solutions shows that the developed approach can serve for a realistic reliability analysis of three-dimensional engineering structures.

Similar content being viewed by others

Abbreviations

- \(a\) :

-

Initial crack depth

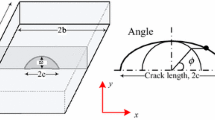

- \(a /c\) :

-

Aspect ratio

- \(b\) :

-

Length of specimen

- \(B^{\text{G}}\) :

-

Deformation matrix for global

- \(B^{\text{L}}\) :

-

Deformation matrix for local

- \(c\) :

-

Initial crack length

- \(C\) :

-

Paris coefficient \(c\)

- \(C^{I}\) :

-

Constant of VCCM

- \(D\) :

-

Material properties matrix

- \({\text{d}}a\) :

-

Crack growth increment

- \({\text{d}}a_{ \max}\) :

-

Maximum crack growth increment

- \({\text{d}}a / {\text{d}}N\) :

-

Crack growth rate

- \(E\) :

-

Modulus of elasticity

- \(E\left[ {} \right]\) :

-

Mean operator

- \(f\) :

-

Body force

- \(F_{\text{G}}\) :

-

Force for global region

- \(F_{\text{L}}\) :

-

Force for local region

- \(F_{ \max}\) :

-

Maximum stress during loading cycle

- \(F_{ \min}\) :

-

Minimum stress during loading cycle

- \(G_{\text{Total}}\) :

-

Total energy release rate

- \(G_{\text{I,II,III}}\) :

-

Energy release rate for modes I, II, and III

- \(h\) :

-

Width of specimen

- \(I\) :

-

Node number around the crack tip

- \(K\) :

-

Stiffness matrix

- \(K_{\text{IC}}\) :

-

Critical stress intensity factor

- \(K_{\text{GG}}\) :

-

Stiffness matrix for global region

- \(K_{\text{LL}}\) :

-

Stiffness matrix for local region

- \(K_{\text{GL}}\) :

-

Stiffness matrix for overlay region

- \(K_{\text{I,II,III}}\) :

-

Stress intensity factor for modes I, II, and III

- \(n\) :

-

Fatigue power parameter

- \(h\) :

-

Nodal force

- \(P_{i}^{I}\) :

-

Failure probability

- \(r\) :

-

Radius of crack growth

- \(R\) :

-

Radius of crack front

- \(S_{1}^{J}\) :

-

Area after crack front

- \(S_{2}^{J}\) :

-

Area before crack front

- \(t\) :

-

Thickness of specimen

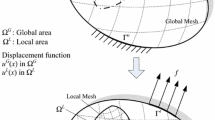

- \(u\) :

-

Displacement function

- \(u^{\text{G}}\) :

-

Displacement function for global

- \(u^{\text{L}}\) :

-

Displacement function for local

- \({\text{Var}}\left[ {} \right]\) :

-

Variance operator

- \(w^{J}\) :

-

Width of element parallel to the crack front

- \(v_{i}^{I}\) :

-

Nodal displacement between the upper and lower crack surfaces

- \(v_{i}\) :

-

Crack opening displacement at the crack surface

- \(v\) :

-

Poisson’s ratio

- \(\varDelta\) :

-

Width of the element in the radial direction

- \(\Delta K_{\text{th}}\) :

-

Threshold value

- \(\Delta K_{\text{eq}}\) :

-

Equivalent stress intensity factor

- \(\Delta K_{{{\text{eq}}_{ \max} }}\) :

-

Maximum equivalent stress intensity factor

- \(\varOmega^{\text{L}}\) :

-

Local mesh region

- \(\varOmega^{\text{G}}\) :

-

Global mesh region

- ε :

-

Strain

- \(\varepsilon^{\text{L}}\) :

-

Strain for local region

- \(\varepsilon^{\text{G}}\) :

-

Strain for global region

- \(\theta\) :

-

Surface crack angle

- \(\varphi_{0}\) :

-

Crack growth angle

- σ :

-

Stress

- \(\sigma_{3i}\) :

-

Cohesive stress at the local axis x3

- \(\varGamma\) :

-

Boundary condition

- \(\varGamma^{\text{GL}}\) :

-

Boundary condition at overlay region

- \(\mu\) :

-

Shear modulus

References

Aguilarespinosa AA, Fellows NA, Durodola JF (2013) Experimental measurement of crack opening and closure loads for 6082-T6 aluminium subjected to periodic single and block overloads and underloads. Int J Fatigue 47:71–82

Akramin MRM, Ariffin AK, Kikuchi M, Abdullah S (2017) Sampling method in probabilistic S-version finite element analysis for initial flaw size. J Braz Soc Mech Sci Eng 39:357–365

Akramin MRM, Shaari MS, Ariffin AK, Kikuchi M, Abdullah S (2015) Surface crack analysis under cyclic loads using probabilistic S-version finite element model. J Braz Soc Mech Sci Eng 37:1851–1865

Beer M, Liebscher M (2008) Designing robust structures—a nonlinear simulation based approach. Comput Struct 86:1102–1122

Brighenti R, Carpinteri A (2013) Surface cracks in fatigued structural components: a review. Fatigue Fract Eng Mater Struct 36:1209–1222

Cao Z, Liu Y (2012) A new numerical modelling for evaluating the stress intensity factors in 3-D fracture analysis. Struct Eng Mech 43:321–336

Carpinteri A (1993) Shape change of surface cracks in round bars under cyclic axial loading. Int J Fatigue 15:21–26

Carpinteri A, Ronchei C, Vantadori S (2013) Stress intensity factors and fatigue growth of surface cracks in notched shells and round bars: two decades of research work. Fatigue Fract Eng Mater Struct 36:1164–1177

Choi S, Grandhi RV, Canfield RA (2007) Reliability-based structural design, 1st edn. Springer, London

De Matos PFP, Nowell D (2009) Experimental and numerical investigation of thickness effects in plasticity-induced fatigue crack closure. Int J Fatigue 31:1795–1804

Duquesnay DL, Underhill PR (2010) Fatigue life scatter in 7xxx Series aluminum alloys. Int J Fatigue 32:398–402

Faszynka S, Lewandowsk J, Rozumek D (2016) Numerical analysis of stress and strain in specimens with rectangular cross-section subjected to torsion and bending with torsion. Acta Mech Autom 10:5–11

Fish J (1992) The S-version of the finite element method. Comput Struct 43:539–547

Hou C-Y (2011) Simulation of surface crack shape evolution using the finite element technique and considering the crack closure Effects. Int J Fatigue 33:719–726

Iyyer N, Sarkar S, Merrill R, Phan N (2007) Aircraft life management using crack initiation and crack growth models—P-3c Aircraft experience. Int J Fatigue 29:1584–1607

Jamal-Omidi M, Falah M, Taherifar D (2014) 3-D fracture analysis of cracked aluminum plates repaired with single and double composite patches using XFEM. Struct Eng Mech 50:525–539

Kikuchi M, Maitireymu M, Sano H (2010) Study on fatigue crack growth criterion 1st report, Paris’ law of a surface crack under pure mode I loading. Nihon Kikai Gakkai Ronbunshu, A Hen/Trans Jpn Soc Mech Eng Part A 76:516–522

Kikuchi M, Wada Y, Maitireyimu M, Sano H (2010) Closure effect on interaction of two surface cracks under cyclic bending. In: American Society of Mechanical Engineers, Pressure Vessels and Piping Division. Bellevue, Washington, USA, July 18–22, 2010

Kikuchi M, Wada Y, Ohdama C (2010) Effect of Kiii on fatigue crack growth behavior. In: American Society of Mechanical Engineers, Pressure Vessels and Piping Division. Bellevue, Washington, USA, July 18–22, 2010

Kikuchi M, Wada Y, Shimizu Y, Li Y (2012) Crack growth analysis in a weld-heat-affected zone using S-Version FEM. Int J Press Vessels Pip 90–91:2–8

Kikuchi M, Wada Y, Shimizu Y, Yulong L (2010) Crack growth analysis in weld-heat affected zone using S-version FEM. In: American Society of Mechanical Engineers, Pressure Vessels and Piping Division. Bellevue, Washington, USA, July 18–22, 2010

Kikuchi M, Wada Y, Shmizu Y, Li Y (2011) Stress corrosion cracking analysis under thermal residual stress field using S-FEM. Key Eng Mater 462–463:431–436

Kikuchi M, Wada Y, Suga K (2011) Surface crack growth simulation under mixed mode cyclic loading condition. Proc Eng 10:427–432

Kikuchi M, Wada Y, Suga K, Ohdama C (2010) Effect of Kiii on fatigue crack growth behavior (factory roof and fatigue crack growth rate). Nihon Kikai Gakkai Ronbunshu, A Hen/Trans Jpn Soc Mech Eng Part A 76:1674–1680

Kim C-Y, Choi J-M, Song J-H (2013) Fatigue crack growth and closure behavior under random loadings in 7475-T7351 aluminum alloy. Int J Fatigue 47:196–204

Kim J-S, An D-H, Lee S-Y, Lee B-Y (2009) A failure analysis of fillet joint cracking in an oil storage tank. J Loss Prev Process Ind 22:845–849

Liu Y, Mahadevan S (2009) Probabilistic fatigue life prediction using an equivalent initial flaw size distribution. Int J Fatigue 31:476–487

Newman JA, Baughman JM, Wallace TA (2010) Investigation of cracks found in helicopter longerons. Eng Fail Anal 17:416–430

Newman JC Jr, Raju IS (1981) An empirical stress-intensity factor equation for the surface crack. Eng Fract Mech 15:185–192

Okada H, Higashi M, Kikuchi M, Fukui Y, Kumazawa N (2005) Three dimensional virtual crack closure-integral method (VCCM) with skewed and non-symmetric mesh arrangement at the crack front. Eng Fract Mech 72:1717–1737

Olsson A, Sandberg G, Dahlblom O (2003) On Latin hypercube sampling for structural reliability analysis. Struct Saf 25:47–68

Paris P, Erdogan F (1960) A critical analysis of crack propagation laws. J Basic Eng 85:528–534

Richard HA, Fulland M, Sander M (2005) Theoretical crack path prediction. Fatigue Fract Eng Mater Struct 28:3–12

Savaidis G, Savaidis A, Zerres P, Vormwald M (2010) Mode I fatigue crack growth at notches considering crack closure. Int J Fatigue 32:1543–1558

Song PS, Shieh YL (2004) Crack growth and closure behaviour of surface cracks. Int J Fatigue 26:429–436

Stephens RI, Fatemi A, Stephens RR, Fuchs HO (2001) Metal fatigue in engineering, 2nd edn. Wiley, New York

Thomas SB, Mhaiskar MJ, Sethuraman R (2000) Stress intensity factors for circular hole and inclusion using finite element alternating method. Theoret Appl Fract Mech 33:73–81

Tian L, Dong L, Bhavanam S, Phan N, Atluri SN (2014) Mixed-mode fracture & non-planar fatigue analyses of cracked I-beams, using a 3D SGBEM-FEM alternating method. Theoret Appl Fract Mech 74:188–199

Tran V-X, Geniaut S (2012) Development and industrial applications of X-FEM axisymmetric model for fracture mechanics. Eng Fract Mech 82:135–157

Underhill PR, Duquesnay DL (2008) The effect of dynamic loading on the fatigue scatter factor for Al 7050. Int J Fatigue 30:614–622

Underhill PR, Duquesnay DL (2009) Effect of small cycles and load spectrum truncation on the fatigue life scatter in 7050 Al alloy. Int J Fatigue 31:538–543

Virkler DA, Hillberry BM, Goel PK (1979) The static nature of fatigue crack propagation. ASME J Eng Mater Technol 101:148–153

Wu WF, Ni CC (2007) Statistical aspects of some fatigue crack growth data. Eng Fract Mech 74:2952–2963

Zhuang Z, Liu Z, Cheng B, Liao J (2014) Chapter 4—fundamental concept and formula of X-Fem. In: Zhuang Z, Cheng ZL, Liao J (eds) Extended finite element method. Academic Press, Oxford, pp 51–73

Acknowledgements

This study was funded by RDU170383 from Universiti Malaysia Pahang and Fundamental Research Grant Scheme (FRGS/1/2017/TK03/UMP/02/24) from Kementerian Pendidikan Malaysia with Number RDU170124.

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Paulo de Tarso Rocha de Mendonça, Ph.D.

Rights and permissions

About this article

Cite this article

Akramin, M.R.M., Ariffin, A.K., Kikuchi, M. et al. Surface crack growth prediction under fatigue load using probabilistic S-version finite element model. J Braz. Soc. Mech. Sci. Eng. 40, 522 (2018). https://doi.org/10.1007/s40430-018-1442-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-018-1442-8