Abstract

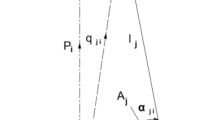

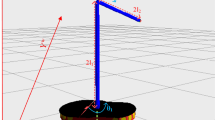

Many planar manipulators are composed of a basic four-bar mechanism. The output delivered by the mechanism deviates from desired one due to factors like link tolerances. The performance needs to be characterized for satisfactory application. This article presents investigation of mechanical error in four-bar mechanism with revolute joints (4R) under the influence of link tolerance. The classical partial derivative formulation (PDA) in uncertainty analysis technique is primarily used for estimating the mechanical error. The error estimation is carried out with proposed modification in PDA formulation. A geometric approach is also developed to estimate the mechanical error for 4R configuration. The mechanical error obtained through PDA is verified using geometric approach. The generalized formulation is demonstrated, and comparative estimation is presented. The methods and conclusions proposed herewith are adaptable for other planar configurations.

Similar content being viewed by others

References

Hartenberg RS, Denavit J (1964) Kinematic synthesis of linkages. McGraw-Hill, New York

Jaiswal A, Jawale HP (2017) Comparative study of four-bar hyperbolic function generation mechanism with four and five accuracy points. Arch Appl Mech 87(12):2037–2054. https://doi.org/10.1007/s00419-017-1310-5

Sandor GN, Erdman AG (1984) Advanced mechanism design: analysis and synthesis. Prentice-Hall Inc, Englewood Cliffs

Chakraborty J (1975) Synthesis of mechanical error in linkages. Mech Mach Theory 10(2):155–165. https://doi.org/10.1016/0094-114X(75)90016-6

Dhande SG, Chakraborty J (1973) Analysis and synthesis of mechanical error in linkages-a stochastic approach. J Eng Ind 95(3):672–676

Du X, Venigella PK, Liu D (2009) Robust mechanism synthesis with random and interval variables. Mech Mach Theory 44(7):1321–1337. https://doi.org/10.1016/j.mechmachtheory.2008.10.003

Chen F-C, Tzeng Y-F, Hsu M-H, Chen W-R (2010) Combining taguchi method, principal component analysis and fuzzy logic to the tolerance design of a dual-purpose six-bar mechanism. Trans Can Soc Mech Eng 34(2):277–293. https://doi.org/10.1139/tcsme-2010-0017

Garrett RE, Hall AS (1969) Effect of tolerance and clearance in linkage design. J Eng Ind 91(1):198–202

Lee SJ, Gilmore BJ, Ogot MM (1993) Dimensional tolerance allocation of stochastic dynamic mechanical systems through performance and sensitivity analysis. J Mech Des 115(3):392–402

Rhyu JH, Kwak BM (1988) Optimal stochastic design of four-bar mechanisms for tolerance and clearance. J Mech Transm Autom Des 110(3):255–262

Sharfi O, Smith M (1983) A simple method for the allocation of appropriate tolerances and clearances in linkage mechanisms. Mech Mach Theory 18(2):123–129. https://doi.org/10.1016/0094-114X(83)90104-0

Tsai M-J, Lai T-H (2004) Kinematic sensitivity analysis of linkage with joint clearance based on transmission quality. Mech Mach Theory 39(11):1189–1206. https://doi.org/10.1016/j.mechmachtheory.2004.05.009

Wu J, Purwar A, Ge Q (2010) Interactive dimensional synthesis and motion design of planar 6R single-loop closed chains via constraint manifold modification. J Mech Robot 2(3):031012

Zhang J, Du X (2011) Time-dependent reliability analysis for function generator mechanisms. J Mech Des 133(3):031005

Augustynek K, Adamiec-Wójcik I (2012) Analysis of mechanisms with flexible beam-like links, rotary joints and assembly errors. Arch Appl Mech 82(2):283–295

Choi J-H, Lee S-J, Choi D-H (1998) Stochastic linkage modeling for mechanical error analysis of planar mechanisms. J Struct Mech 26(3):257–276

Dubowsky S, Gardner TN (1975) Dynamic interactions of link elasticity and clearance connections in planar mechanical systems. J Eng Ind 97(2):652–661

Flores P (2015) On the study of the kinematic position errors due to manufacturing and assembly tolerances. In: Kecskeméthy A, Geu Flores F (eds) Interdisciplinary applications of kinematics. Mechanisms and machine science, vol 26. Springer, Cham

Kolhatkar SA, Yajnik KS (1970) The effects of play in the joints of a function-generating mechanism. J Mech 5(4):521–532

Li X, Ding X, Chirikjian GS (2015) Analysis of angular-error uncertainty in planar multiple-loop structures with joint clearances. Mech Mach Theory 91:69–85

Mallik AK, Dhande SG (1987) Analysis and synthesis of mechanical error in path-generating linkages using a stochastic approach. Mech Mach Theory 22(2):115–123

Nzue R-MA, Brethé JF, Vasselin E, Lefebvre D (2010) Comparative analysis of the repeatability performance of a serial and parallel robot. In: 2010 IEEE/RSJ international conference on intelligent robots and systems (IROS). IEEE, pp 63–68

Rao SS, Reddy CP (1979) Mechanism design by chance constrained programming techniques. Mech Mach Theory 14(6):413–424

Ting K-L, Liu Y-W (1991) Rotatability laws for n-bar kinematic chains and their proof. J Mech Des 113(1):32–39

Ting K-L, Zhu J, Watkins D (2000) The effects of joint clearance on position and orientation deviation of linkages and manipulators. Mech Mach Theory 35(3):391–401

Zhang X, Zhang X (2016) A comparative study of planar 3-rrr and 4-rrr mechanisms with joint clearances. Robot Comput Integr Manuf 40:24–33

Zhu J, Ting K-L (2000) Uncertainty analysis of planar and spatial robots with joint clearances. Mech Mach Theory 35(9):1239–1256

Erkaya S (2017) Effects of joint clearance on motion accuracy of robotic manipulators. J Mech Eng (in press). http://www.sv-jme.eu/article/effects-of-joint-clearance-on-motion-accuracy-of-robotic-manipulators

Erkaya S, Uzmay I (2008) A neuralgenetic (nn-ga) approach for optimising mechanisms having joints with clearance. Multibody Syst Dyn 20(1):69–83

Erkaya S, Uzmay I (2009a) Determining link parameters using genetic algorithm in mechanisms with joint clearance. Mech Mach Theory 44(1):222–234

Erkaya S, Uzmay I (2010) Experimental investigation of joint clearance effects on the dynamics of a slider-crank mechanism. Multibody Syst Dyn 24(1):81–102

Erkaya S, Uzmay B (2014) Modeling and simulation of joint clearance effects on mechanisms having rigid and flexible links. J Mech Sci Technol 28(8):2979–2986

Erkaya S (2012a) Effects of balancing and link flexibility on dynamics of a planar mechanism having joint clearance. Sci Iran 19(3):483–490

Erkaya S, Uzmay İ (2009b) Investigation on effect of joint clearance on dynamics of four-bar mechanism. Nonlinear Dyn 58(1–2):179

Erkaya S (2013) Trajectory optimization of a walking mechanism having revolute joints with clearance using anfis approach. Nonlinear Dyn 71(1–2):75–91

Meng J, Zhang D, Li Z (2009) Accuracy analysis of parallel manipulators with joint clearance. J Mech Des 131(1):011013

Li-Xin X, Yong-Gang L (2014) Investigation of joint clearance effects on the dynamic performance of a planar 2-dof pick-and-place parallel manipulator. Robot Comput Integr Manuf 30(1):62–73

Tsai M-J, Lai T-H (2008) Accuracy analysis of a multi-loop linkage with joint clearances. Mech Mach Theory 43(9):1141–1157

Tian Q, Flores P, Lankarani HM (2018) A comprehensive survey of the analytical, numerical and experimental methodologies for dynamics of multibody mechanical systems with clearance or imperfect joints. Mech Mach Theory 122:1–57

Erkaya S (2012b) Investigation of joint clearance effects on welding robot manipulators. Robot Comput Integr Manuf 28(4):449–457

Jawale HP, Thorat HT (2013) Positional error estimation in serial link manipulator under joint clearances and backlash. J Mech Robot 5(2):021003

Jawale H, Thorat H (2014) Positional accuracy analysis in serial chain and four-bar closed chain manipulator. In: ASME 2014 international mechanical engineering congress and exposition. American Society of Mechanical Engineers, pp V011T14A010–V011T14A010

Choubey M, Rao AC (1982) Synthesizing linkages with minimal structural and mechanical error based upon tolerance allocation. Mech Mach Theory 17(2):91–97. https://doi.org/10.1016/0094-114X(82)90039-8

Flores P (2011) A methodology for quantifying the kinematic position errors due to manufacturing and assembly tolerances. Strojniški vestnik-J Mech Eng 57(6):457–467. https://doi.org/10.5545/sv-jme.2009.159

Lakshminarayana K, Narayanamurthi R (1971) On the analysis of the effect of tolerances in linkages. J Mech 6(1):59–67

Agarwal S, Bandyopadhyay S (2017) Design of six-bar function generators using dual-order structural error and analytical mobility criteria. Mech Mach Theory 116:326–351. https://doi.org/10.1016/j.mechmachtheory.2017.04.016

Karan B, Vukobratović M (1994) Calibration and accuracy of manipulation robot models an overview. Mech Mach Theory 29(3):479–500

Popescu I, Marghitu DB, Stoenescu ED (2006) Kinematic chains with independent loops and spatial system groups. Arch Appl Mech 75(10):739–754

Zhan Z, Zhang X, Jian Z, Zhang H (2018) Error modelling and motion reliability analysis of a planar parallel manipulator with multiple uncertainties. Mech Mach Theory 124:55–72

Caro S, Binaud N, Wenger P (2009) Sensitivity analysis of 3-rpr planar parallel manipulators. J Mech Des 131(12):121005

Hafezipour M, Khodaygan S (2017) An uncertainty analysis method for error reduction in end-effector of spatial robots with joint clearances and link dimension deviations. Int J Comput Integr Manuf 30(6):653–663

Khodaygan S, Hafezipour M (2015) Error reduction in spatial robots based on the statistical uncertainty analysis. SAE Int J Mater Manuf 8(2015–01–0435):263–270

Ting K-L, Long Y (1996) Performance quality and tolerance sensitivity of mechanisms. Trans Am Soc Mech Eng J Mech Des 118:144–150

Wu W, Rao SS (2004) Interval approach for the modeling of tolerances and clearances in mechanism analysis. Trans Am Soc Mech Eng J Mech Des 126(4):581–592

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Victor Juliano De Negri.

Rights and permissions

About this article

Cite this article

Jawale, H.P., Jaiswal, A. Investigation of mechanical error in four-bar mechanism under the effects of link tolerance. J Braz. Soc. Mech. Sci. Eng. 40, 383 (2018). https://doi.org/10.1007/s40430-018-1299-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-018-1299-x