Abstract

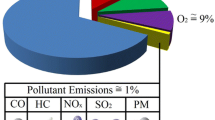

Development of any country depends upon the availability of transport facility. Oil is the main source of energy which is now consumed up to 30% for transport facility in the world. The fossil fuel stocks all over the world are reduced due to industrial growth, innovation in transport vehicles and expanding urbanization. The application of biodiesel has shown a positive impact in minimizing these issues. Jatropha, locally known as ratanjot, is most considerable feedstock in India. Biodiesel (Jatropha methyl ester) of it as an environmentally and eco-friendly second-generation fuel has the potential to provide comparable compression ignition (CI) engine performance and enhance the lubrication. In this paper, the work is carried out on a single-cylinder variable compression ratio CI engine fuelled with various blends of Jatropha methyl ester with diesel to study vibration, performance and emission characteristics of the engine and its optimization using Taguchi method as well as multiple regression analysis. The experiments are conducted on a single-cylinder CI engine for various operating parameters with different levels, viz., compression ratio, fuel injection pressure, fuel fraction, and injection timing. The load for engine has been incremented with the step 1/3% of full load from zero to full load. This study aims first to address the optimal level of operating parameters and then evaluate by regression model of the output variables, viz., acceleration of engine head in linear and lateral directions, specific fuel consumption, brake thermal efficiency, and oxides of nitrogen as function of operating parameters. Taguchi’s L 16 orthogonal array is applied for reducing the number of runs and time for experiment. The obtained optimal combination of the operating parameters in the single-cylinder CI engine operated on Jatropha biodiesel blend for better output is compression ratio 15.5, injection pressure 270 bar, fuel fraction 20% and injection timing 23 °bTDC. The results demonstrate the Jatropha methyl ester can be applied as an alternative to the petroleum diesel in conventional diesel engines.

Similar content being viewed by others

Abbreviations

- ANOVA:

-

Analysis of variance

- BTE:

-

Brake thermal efficiency

- BSFC:

-

Brake specific fuel consumption

- bTDC:

-

Before top dead centre

- CO:

-

Carbon monoxide

- CO2 :

-

Carbon dioxide

- CR:

-

Compression ratio

- CI:

-

Compression ignition

- FF:

-

Fuel fraction

- HC:

-

Hydro carbon

- IP:

-

Injection pressure

- IT:

-

Injection timing

- NO x :

-

Nitrogen oxide

- RMS:

-

Root mean square

- SFC:

-

Specific fuel consumption

- X Accel :

-

Vibration acceleration RMS (linear direction) m/s2

- Y Accel :

-

Vibration acceleration RMS (lateral direction) m/s2

References

Owolabi RU, Adejumo AL, Aderibigbe AF (2012) Biodiesel: Fuel for the future (A brief review). Int J Energy Eng 2:223–231

BP statistical review of world energy (2014) Energy academy, Heriot-Watt University, Pureprint Group Limited, Edinburgh. 63rd edn; https://www.bp.com/content/dam/bp-country/de_de/PDFs/brochures/BP-statistical-review-of-world-energy-2014-full-report.pdf

Bala M, Balat H (2010) Progress in biodiesel processing. Appl Energy 87:1815–1835

Murugesan A, Umarani C, Subramanian R, Nedunchezhian N (2009) Bio-diesel as an alternative fuel for diesel engines—a review. Renew Sustain Energy Rev 13:653–662

Ashraful AM, Masjuki HH, Kalam MA, Rizwanul Fattah IM, Imtenan S, Shahir SA, Mobarak HM (2014) Production and comparison of fuel properties, engine performance and emission characteristics of biodiesel from various non-edible vegetable oils: a review. Energy Convers Manage 80:202–228

Bankovic-Ilic IB, Stamenkovic OS, Veljkovic VB (2012) Biodiesel production from non-edible plant oils. Renew Sustain Energy Rev 16(6):3621–3647

Leung DYC, Wu X, Leung MKH (2010) A review on biodiesel production using catalyzed transesterification. Appl Energy 87(4):1083–1095

Karmakar A, Karmakar S, Mukherjee S (2010) Properties of various plants and animals feedstocks for biodiesel production. Bio Resour Technol 101:7201–7210

Tiwari AK, Kumar A, Raheman H (2007) Biodiesel production from Jatropha oil (Jatropha curcas) with high free fatty acids—an optimized process. Biomass Bioenerg 31:569–575

Puhan S, Vedaraman N, Rambrahmam BV, Nagrajan G (2005) Mahua (madhuca indica) seed oil: a source of renewable energy in india. J Sci Ind Res 64:890–896

Habibullah H, Masjuki HH, Kalam MA, Rizwanul Fattah IM, Ashraful AM, Mobara HM (2014) Biodiesel production and performance evaluation of coconut palm and their combined blend with diesel in a single—cylinder diesel engine. Energy Convers Manage 87:250–257

Tuccar G, Tosun E, Ozgur T, Aydın K (2014) Diesel engine emissions and performance from blends of citrus sinensis biodiesel and diesel fuel. Fuel 32:7–11

Muralidharan K, Vasudevan D, Sheeba K (2011) Performance, emission and combustion characteristics of biodiesel fuelled variable compression ratio engine. Energy 36:5385–5393

Sayin C, Gumus M, Canakci M (2013) Influence of injector hole number on the performance and emissions of a DI diesel engine fueled with biodiesel-diesel fuel blends. Appl Therm Eng 61:121–128

Al-Hasan M (2003) Effect of ethanol–unleaded gasoline blends on engine performance and exhaust emission. Energy Convers Manage 44:1547–1561

Ganapathy T, Gakkhar R, Murugesan K (2015) Influence of injection timing on performance, combustion and emission characteristics of Jatropha biodiesel engine. Appl Energy 88:4376–4386

Hafizil M, Yasina M, Mamata R, Yusopa AF, Parukaa P, Yusafb T, Najafi G (2015) Effects of exhaust gas recirculation (EGR) on a diesel engine fuelled with palm-biodiesel. Energy Procedia 75:30–36

Agarwal D, Singh Kumar, Agarwal A (2011) Effect of exhaust gas recirculation (EGR) on performance, emissions, deposits and durability of a constant speed compression ignition engine. Appl Energy 88:2900–2907

Abd-Alla GH (2002) Using exhaust gas recirculation in internal combustion engines—a review. Energy Conver Manag 43:1027–1042

Dangar H, Rathod GP (2013) Combine effect of exhaust gas recirculation (EGR) and varying inlet air pressure on performance and emission of diesel engine. J Mech Civil Eng 6:26–33

Elfasakhany A (2016) Performance and emissions of spark-ignition engine using ethanol–methanol–gasoline, n-butanol-iso-butanol–gasoline and iso-butanol–ethanol–gasoline blends—a comparative study. Eng Sci Technol Int J 19:2053–2059. https://doi.org/10.1016/j.jestch.2016.09.009

Balaji D, Govindarajan P, Venkatesan J (2012) Emission and combustion characteristics of SI engine working under gasoline blended with ethanol oxygenated organic compounds. Am J Environ Sci 6(6):495–499

Murugesan A, Subramaniam D, Vijayakumar C, Avinash A, Nedunchezhian N (2012) Analysis on performance, emission and combustion characteristics of diesel engine fueled with methyl–ethyl esters. J Renew Sustain Energy 4:063116–1–063116–13. https://doi.org/10.1063/1.4767911

Taghizadeh-Alisaraei A, Ghobadian B, Avakoli-Hashjin T, Mohtasebi Seyyed Saeid, Rezaei-asl A, Azadbakht M (2016) Characterization of engine’s combustion-vibration using diesel and biodiesel fuel blends by time-frequency methods—a case study. Renew Energy 95:422–432

Alisaraei AT, Ghobadian B, Hashjin TT, Mohtasebi SS (2012) Vibration analysis of a diesel engine using biodiesel and petrodiesel fuel blends. Fuel 120:414–422

Jindal S (2012) Vibration signatures of a biodiesel fueled CI engine and effect of engine parameters. Int J Energy Environ 3:151–160

Gravalos I, Smoshou D, Gialamas T (2011) Vibration effect on spark iginition engine fuelled with methanol gasoline blends. J Agri Machin Sci 7:367–372

Patel C, Lee S, Tiwari N, Agarwal AK, Lee CS, Park Sungwook (2016) Spray characterization, combustion, noise and vibrations investigations of Jatropha biodiesel fuelled genset engine. Fuel 185:410–420

Chiatti G, Chiavola O, Palmieri F (2016) Vibration and acoustic characteristics of a city-car engine fueled with biodiesel blends. Appl Energy 5:186–192

Shaikh MF, Umale S (2014) Noise and vibration analysis of diesel engine using diesel and Jatropha biodiesel. Int J Eng Trends 12:228–231

Sastry GRK, Venkateswarlu K, Yousufuddin S, Rmurthy BS (2012) Performance, vibration and emission analysis of diesel engine fuelled with fish oil bio diesel blends. Int J Adv Eng Technol 3:116–120

Sayin Cenk, Canakci Mustafa (2009) Effects of injection timing on the engine performance and exhaust emissions of a dual-fuel diesel engine. Energy Convers Manage 50:203–213

Uludamar E, Tosun E, Aydın K (2016) Experimental and regression analysis of noise and vibration of a compression ignition engine fuelled with various biodiesels. Fuel 177:326–333

Ganapathy T, Murugesan M, Gakkhar RP (2009) Performance optimization of Jatropha biodiesel engine model using Taguchi approach. Appl Energy 86(11):2476–2486

Tandale MS, Garjepatil GV, Jadhav SD (2016) Optimization of performance and emission characteristics of compressed ignition engine operated on Mahua biodiesel using Taguchi and multiple regression analysis, In: Proceedings of the World Congress on Engineering 2

Jain S, Sharma MP (2010) Prospects of biodiesel from Jatropha in India—a review. Renew Sustain Energy Rev 14:763–771

Agarwal D, Agarwal AK (2007) Performance and emissions characteristics of Jatropha oil (preheated and blends) in a direct injection compression ignition engine. Appl Therm Eng 27:2314–2323

Liu F, He H, Zhang C, Feng Z, Zheng L, Xie Y, Hu T (2010) Selective catalytic reduction of NO with NH3 over iron titanate catalyst–catalytic performance and characterization. Appl Catal B Environ 96:408–420

Gadhave ND, Gawande SH (2017) Optimization of CI engine vibration characteristics operated on Jatropha methyl ester using Taguchi and multiple regression analysis. Int Rev Mech Eng 11(6):367–372

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interests regarding the publication of this paper.

Additional information

Technical Editor: Katia Lucchesi Cavalca Dedini.

Rights and permissions

About this article

Cite this article

Gadhave, N.D., Gawande, S.H. Optimizing performance of the Jatropha biodiesel engine using Taguchi approach. J Braz. Soc. Mech. Sci. Eng. 40, 235 (2018). https://doi.org/10.1007/s40430-018-1153-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-018-1153-1