Abstract

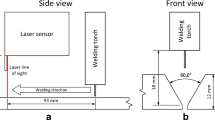

In a recent research related to technological application in monitoring and control of welding, the use of various approaches to improve the productivity and quality through the development of techniques and automatic control systems is observed. This paper presents a methodology for modelling and control of the weld height reinforcement, allowing adjusting the process parameters, which can be implemented in the field of research or, in certain cases, in the industrial sector as an approach to the control of weld bead geometries. This was developed for the geometric characteristic studied in an integrated system of images acquisition, modelling and control system. The weld bead formation is measured through an acquisition system and processing of images using a low-cost web cam. The wire feed speed, the welding speed and voltage are predicted using an artificial neural network based on the desired weld height reinforcement. The control system is based on fuzzy logic.

Similar content being viewed by others

References

Villani P, Modenesi P, Bracarense A (2005) Soldagem fundamentos e tecnologia, 1st edn. Editora UFMG, Belo Horizonte

Jahanzaib M, Hussain S, Wasim A (2017) Modeling of weld bead geometry on HSLA steel using response surface methodology. Int J Adv Manuf Technol 89:2087

Mistry PKJ (2016) Effect of process parameters on bead geometry and shape relationship of gas metal arc weldments. Int J Adv Res Mech Eng Technol (IJARMET) 2:24–27

Cruz JAG (2014) Uma metodologia para modelagem e controle da altura do reforço e da largura do cordão de solda no processo GMAW. Dissertação de Mestrado em Sistemas Mecatrônicos, Universidade de Brasília, Brasil

Ferneda E (2006) Redes neurais e sua aplicação em sistemas de recuperação de informação. Jornal Ciência da Informação 35:25–30

Mkrtchyan L (2010) Alternative solutions to traditional approaches to risk analysis and decision making using fuzzy logic. PhD Thesis, IMT School for Advanced Studies Lucca, Lucca, Italy

Godoy M, Shaw IS (2007) Controle e Modelagem Fuzzy. Revista e Ampliada. Editora Blucher 2:200–201

Lopera JEP, Alfaro S (2012) Response surface methodology to model the projected spray metal transfer in GMAW. ABCM Symposium Series in Mechatronics, Computer Vision, 5:29–38. ISBN 978-85-85769-50-5

Torres EMM, Cruz JAG, Lopera JEP, Alfaro S (2014) Parameter optimization in GMAW process with solid and metal-cored wires. ABCM Symposium Series in Mechatronics, Modelling, Control and Identification, 6:141–151. ISBN 978-85- 85769-52-9

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Márcio Bacci da Silva.

Rights and permissions

About this article

Cite this article

Cruz, J.G., Torres, E.M. & Absi Alfaro, S.C. Modelling and control of weld height reinforcement in the GMAW process. J Braz. Soc. Mech. Sci. Eng. 40, 164 (2018). https://doi.org/10.1007/s40430-018-1080-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-018-1080-1