Abstract

Lithium amidoborane (LiAB) is known as an efficient hydrogen storage material. The dehydrogenation reaction of LiAB was studied employing temperature-programmed desorption methods at varying temperature and H2 pressure. As the dehydrogenation products are in amorphous form, the XRD technique is not useful for their identification. The two-step decomposition temperatures (74 and 118 °C) were found to hardly change in the 1–80 bar pressure range. This is related either to kinetic effects or to thermal dependence of the reaction enthalpy. Further, the possible joint decomposition of LiNH2BH3 with LiBH4 or MgH2 was investigated. Indeed LiBH4 proved to destabilize LiAB, producing a 10 °C decrease of the first-step decomposition temperature, whereas no significant effect was observed by the addition of MgH2. The 5LiNH2BH3 + LiBH4 assemblage shows improved hydrogen storage properties with respect to pure lithium amidoborane.

Similar content being viewed by others

Introduction

Energy is one of the most significant factors which is discussed in the economic literature. Today, all economic and industrial activities are strongly affected by energy consumption and use efficiency. Energy production from fossil fuels is one of the important causes of greenhouse gas emissions and climate change. Further, due to the limited resources of oil, coal, and natural gas, alternative solutions should be envisaged to support more sustainable demands. In other words, shortage of fossil fuel reserves and the negative effects of greenhouse gas emission on the climate indicate the necessity of increasing the contribution of renewable and sustainable sources to energy consumption. In this scenario, hydrogen is known to be an energy carrier with a great potential interest [1, 2], and the step of its storage in the industrial cycle has a crucial importance.

Various types of solid materials have shown the capability for hydrogen storage in a specific working condition [3, 4]. High pressure and low temperature is required to store hydrogen in metal–organic frameworks (MOF) [5, 6], while other types of materials such as metal hydrides or complex hydrides [7,8,9,10,11,12], and in some cases a mixture of these compounds [13,14,15], can be applied as storage materials at ambient conditions.

Ammonia borane NH3BH3, synthesized first in 1955 [16], is a solid compound at room temperature with 19.6 wt% (H) hydrogen capacity. The endothermic dehydrogenation reaction of this compound occurs in three steps [17]:

Reaction (1) takes place in the temperature range 70–112 °C, while the reactions (2) and (3) occur between 110 and 200 °C. The borazine produced during reaction (3) can be harmful for the fuel cell catalysts. A number of investigations have focused on the dehydrogenation properties of NH3BH3 [18,19,20,21,22,23]. In previous studies, one protonic hydrogen of ammonia borane was substituted by alkali or alkaline-earth elements to achieve a chemically modified compound with acceptable hydrogenation/dehydrogenation behaviour [24,25,26]. Xiong et al. [24] synthesized lithium amidoborane, LiNH2BH3 (LiAB), during a direct reaction of LiH with NH3BH3 during the ball milling process, reporting the following reaction:

LiNH2BH3 was reported to release hydrogen at around 92 °C without any trace of borazine or other byproducts, while the dehydrogenation temperature of NH3BH3 is about 108–154 °C along with a small release of borazine. In addition, LiNH2BH3 is quite stable as a solid powder in air at ambient pressure and temperature.

The gravimetric capacity of this compound is 10.9%, which can be yielded within 1 h according to the reaction:

Consequently, this compound was emphasized as one of the promising storage material for hydrogen in the annual progress report of DOE hydrogen program in 2008 [26]. To apply this material as an energy carrier for vehicular applications, the kinetics of hydrogen release, the reversibility, and the temperature of dehydrogenation reaction have to be optimized. The first report on the destabilization of hydrides was given by Reilly and Wiswall [27]. The basic idea was to let the hydride react with some appropriate compound so as to lower the dehydrogenation enthalpy and consequently, the reaction temperature. This required that the formed mixed dehydrogenated product was much more stable than the simple product of the original reaction [28].

The present study was first undertaken to investigate the thermodynamic or kinetic barriers in the dehydrogenation reaction of LiNH2BH3 by monitoring the effect of H2 pressure in dynamic conditions. The second aim of this research was to detect possible destabilization effects of additive hydrides such as MgH2 and LiBH4 on lithium amidoborane, to further lower its dehydrogenation temperature. These additives were selected because (a) they are themselves well-known and characterized for hydrogen storage properties, with large H2 capacity and satisfactory kinetic performance, and (b) they have already proved to work as destabilizers with each other [29] and with other systems [28, 30].

Experimental methods and synthesis of materials

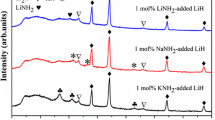

Lithium hydride and NH3BH3 were employed in the synthesis of LiNH2BH3 [31]. Commercial LiH and amidoborane in 1:1 molar ratio were loaded into a stainless-steel vial containing 1 cm diameter balls, with ball-to-powder weight ratio equal to 30. The milling was performed in an argon atmosphere at 400 rounds min−1 for 24 h by a Retsch planetary mill apparatus. X-ray diffraction (Bruker D8 Advance X-ray powder diffractometer) with Cu Kα radiation was employed to analyze the produced powder; owing to air sensitivity, this was kept in a special sample holder under argon atmosphere during measurements. It was found that a mostly pure orthorhombic α phase of lithium amidoborane [31] had been obtained, with a trace of post-decomposed product of LiNH2BH3·NH3BH3 (Fig. 1a).

X-ray diffraction patterns of: a as-synthesized LiNH2BH3, with marked peaks (open circle) for α-LiNH2BH3 and (filled asterisk) for the post-decomposed product of LiNH2BH3·NH3BH3 [31]; b amorphous final decomposition product of LiNH2BH3

On mixing commercial LiBH4 or MgH2 (Sigma-Aldrich) with the synthesized LiNH2BH3 powder, and grinding them in an agate mortar, the LiNH2BH3 + LiBH4 and LiBH4 + MgH2 composites were prepared. Every handling step was performed in a glove box filled with recirculated argon atmosphere.

A Sievert-type equipment (Advanced Materials Corporation) was employed to measure the progress of decomposition reaction vs. temperature and hydrogen pressure in dynamic conditions. 0.6 g of the selected sample was loaded in a small stainless-steel crucible connected to the pressure manifold and inserted in a furnace. At room temperature, after three proper washing cycles, hydrogen gas (99.9995%) was introduced into the sample holder to reach the desired pressure. The dehydrogenation experiments were performed by increasing the sample temperature from 25 to 180 °C with 1 °C min−1 rate at constant pressure; different pressure values were selected in the 1–80 bar (at room temperature) range. During temperature-programmed desorption (TPD) dynamic runs, the amount of released hydrogen is determined from the pressure change in the sample container.

Results and discussion

Dehydrogenation of pure LiNH2BH3

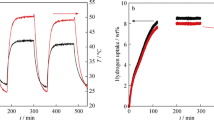

Four TPD measurements were performed on LiAB in the Sievert’s apparatus, under 1, 10, 20, and 80 bar of hydrogen pressure. The results are shown in Fig. 2.

Each curve shows two inflexion points, suggesting that two different reactions (A, B) occur during decomposition. The first step is quite sharp, and it is responsible for about 40% of the total hydrogen release; at step B, instead, the curve is much less steep and the process covers a wide thermal range. The corresponding T values have been obtained from minima in the derivative curve of TPD data, and they are reported in Table 1. Considering the accuracy of the built-in pressure transducer and thermocouple, the position of the furnace heating zone in each sample loading experiment and the human error in the homogeneity of sample preparation a certain level of temperature tolerance is expected. As a result, the dependency of reaction temperature and the applied pressure is not statistically significant, except perhaps a slight tendency to increase with p for the A case.

The X-ray diffraction pattern of decomposed LiAB (Fig. 1b) shows that the products are fully amorphous, so it is not possible to define the dehydrogenation reaction by this technique. This observation is in agreement with the results given by Wu et al. [26].

Xiong et al. [24] reported a reaction enthalpy ΔrH of − 3 to − 5 kJ mol−1 (H2) (measured by DSC method in Ar flow at room pressure) for the slightly exothermic A process. Therefore, in conditions of ideal thermodynamic equilibrium, an increase of pressure should lead to a decrease of decomposition temperature, according to the van’t Hoff equation:

where p0 = 1 bar, T0 = T (1 bar), and the reaction enthalpy is referred to T0.

On using the ΔrH = − 5 kJ mol−1 literature value, one would obtain the decomposition temperatures reported in Table 2. These contrast sharply with the experimental result that the dehydrogenation temperature is practically insensitive to a pressure increase (Table 1). A similar difference between theoretical and actual temperature was also observed in the case of NH3BH3 by Baitalow et al. [32]. Such phenomena are usually explained by assuming that, close to room temperature and in dynamic conditions such as those of the TPD experiment, the reaction may be controlled by kinetic rather than ideal thermodynamic barriers, so as to make predictions based on the van’t Hoff equation wrong. However, in addition to these arguments, purely thermodynamic reasons can also account for the failure of formula (4), when the reaction enthalpy is very small in absolute value. Let us recall that Eq. (4) relies upon the zeroth order approximation that reaction enthalpy and entropy are independent of temperature; on upgrading instead to first-order dependence, an additional term should be introduced according to:

where ΔrCp is the heat capacity change of reaction at T0. Now, for significant values of |ΔrH| (of the order of tens of kJ mol−1), the second term in the sum is usually negligible with respect to the first one, and the van’t Hoff equation in form (4) is quite adequate for all purposes. If, on the other hand, |ΔrH| amounts to only few kJ mol−1, then the second term becomes important and on neglecting it, large errors can be introduced in the calculation of the decomposition temperature T as a function of p. We believe that this applies to the present case.

Combined reaction of LiAB with MgH2 and LiBH4

The results of TPD measurements on the LiAB + MgH2 and LiAB + LiBH4 composites are shown and compared with those of LiAB in Fig. 3, and the corresponding temperatures of the first-observed dehydrogenation process (A) are listed in Table 3.

Dynamic thermal decomposition of \({\text{LiNH}}_{2} {\text{BH}}_{3} + {\text{MgH}}_{2}\) (open circle), \({\text{LiNH}}_{2} {\text{BH}}_{3} + {\text{LiBH}}_{4}\) (open square), and pure \({\text{LiNH}}_{2} {\text{BH}}_{3}\) (open triangle) under 1 bar hydrogen pressure (heating rate 1 °C min−1 in Sievert apparatus)

The presence of MgH2 appears to hardly affect the LiAB decomposition process, as the LiAB + MgH2 curve is almost overlapped with that of pure LiAB. On the other hand, significant changes ensue with the addition of LiBH4 to LiAB. First, the decomposition temperature for the A process decreases by about 10 °C. Second, a much larger release of hydrogen follows quickly, reaching full dehydrogenation at 100 °C well below the temperature observed for pure LiAB. Just after the A reaction, a weak shoulder appears, followed by a sharp inflexion point at about 70 °C; this might correspond to the B process at a much lower temperature, or it could be a different reaction. Curves are normalized in Fig. 3 for better comparison; indeed, the absolute hydrogen loss of 7.2 wt% (H) for the LiAB + LiBH4 composite (Table 4) shows that slightly more than 2H2 molecules are released as for pure LiAB, so that it could be questioned whether LiBH4 is really involved in the reaction (cf. its decomposition temperature of 300 °C at 1 bar in pure form). However, the substantial decrease of reaction temperature (from 74 to 64 °C), indicating an enthalpy reduction, supports clearly the joint decomposition of the two hydrides. This can only be made consistent with the small hydrogen loss of 7.2% on assuming a different reaction stoichiometry.

To investigate this hypothesis, TPD runs were done on samples with different compositions, keeping all other conditions identical. The result for 5LiAB + LiBH4 is plotted in Fig. 4, together with the curves of LiAB + LiBH4 and of pure LiAB for comparison. A very similar or even slightly lower A reaction temperature is observed, with respect to the LiAB + LiBH4 case, but the ensuing part of the curve resembles more that of pure LiAB. However, the total amount of released hydrogen is larger than expected in that instance (Table 4). We observe an excess of about 3 H atoms with reference to the 20 expected (4 H per LiAB formula unit), which fits with the assumption that LiBH4 is jointly decomposed together with 5LiAB according to the following reaction scheme:

Dynamic thermal decomposition of \(5{\text{LiNH}}_{2} {\text{BH}}_{3} + {\text{LiBH}}_{4}\) (open circle), \({\text{LiNH}}_{2} {\text{BH}}_{3} + {\text{LiBH}}_{4}\) (open square) and pure \({\text{LiNH}}_{2} {\text{BH}}_{3}\) (open triangle) under 1 bar hydrogen pressure (heating rate 1 °C min−1 in Sievert apparatus)

This result suggests that joint dehydrogenation of LiBH4 with LiAB is actually observed only in ratios less than 1:1, whereas for larger amounts of LiBH4 a fraction of lithium borohydride does not react and then the hydrogen yield is less than expected.

Conclusions

The dehydrogenation reaction of lithium amidoborane was shown to be scarcely affected by increasing the p(H2) pressure up to 80 bar. This contrasts with the expected decrease of the reaction temperature, according to the small negative reaction enthalpy reported in the literature. However, it was shown that the predictions supported by the simple van’t Hoff equations may not be reliable in case the reaction enthalpy is small in absolute value, as neglecting the temperature dependence of the reaction enthalpy may not be justified in this case.

On investigating the decomposition of LiAB + MgH2 and LiAB + LiBH4 composites, it was found that the first additive has no effect on the LiAB properties. On the other hand, the second one lowers significantly the reaction temperature from 74 to 64 °C, so as to support a real joint decomposition of the two hydrides by decreasing the dehydrogenation enthalpy. While pure LiNH2BH3 releases approximately 9.8 wt% (H) upon heating to 180 °C, LiNH2BH3 + LiBH4 and 5LiNH2BH3 + LiBH4 yield about 7.2 and 10.9 wt% (H) under the same conditions, respectively. Thus, LiBH4 is proved to react with LiAB in the 1:5 rather than 1:1 stoichiometric ratio, according to the suggested reaction \(5{\text{LiNH}}_{2} {\text{BH}}_{3} ( {\text{s)}} + {\text{LiBH}}_{4} \to 5{\text{LiNBH(s)}} + {\text{LiH}} + 23/2{\text{H}}_{2} ( {\text{g)}}\). The 5LiAB + LiBH4 composite is therefore a promising material for hydrogen storage applications.

Change history

06 September 2019

The original version of this article is missing the below acknowledgements section.

References

Dincer, I.: Renewable energy and sustainable development: a crucial review. Renew. Sustain. Energy Rev. 4, 157–175 (2000)

Jain, I.P.: Hydrogen the fuel for 21st century. Int. J. Hydrogen Energy 34, 7368–7378 (2009)

Hirscher, M., Katsuhiko, H.: Handbook of Hydrogen Storage. Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim (2010)

Sandrock, G.: A panoramic overview of hydrogen storage alloys from a gas reaction point of view. J. Alloys Compd. 293, 877–888 (1999)

Braga, S.F., Colucci, V.R., Baughman, R.H., Galvão, D.S.: Hydrogen storage in carbon nanoscrolls: an atomistic molecular dynamics study. Chem. Phys. Lett. 441, 78–82 (2007)

Han, S.S., Furukawa, H., Yaghi, O.M., Goddard, William A.: Covalent organic frameworks as exceptional hydrogen storage materials. J. Am. Chem. Soc. 130, 11580–11581 (2008)

Orimo, S.-I., Nakamori, Y., Eliseo, J.R., Züttel, A., Jensen, C.M.: Complex hydrides for hydrogen storage. Chem Rev 107, 4111–4132 (2007)

Chen, P., Xiong, Z., Luo, J., Lin, J., Tan, K.L.: Interaction of hydrogen with metal nitrides and imides. Nature 420, 302–304 (2002)

Jain, I.P., Lal, C., Jain, A.: Hydrogen storage in Mg: a most promising material. Int. J. Hydrogen Energy 35, 5133–5144 (2010)

Crivello, J.-C., Dam, B., Denys, R.V., Dornheim, M., Grant, D.M., Huot, J., Jensen, T.R., de Jongh, P., Latroche, M., Milanese, C., et al.: Review of magnesium hydride-based materials: development and optimization. Appl. Phys. A Mater. Sci. Process. 122, 1–20 (2016)

Marder, T.B.: Will we soon be fueling our automobiles with ammonia-borane, Angew. Chem. Int. Ed. 46, 8116–8118 (2007)

Jepsen, L.H., Paskevicius, M., Jensen, T.R.: Nanostructured and complex hydrides for hydrogen storage. Nanotechnol. Energy Sustain. 2, 415–431 (2017)

Yang, J., Sudik, A., Siegel, D.J., Halliday, D., Drews, A., Carter, R.O., Wolverton, C., Lewis, G.J., Sachtler, J.W.A., Low, J.J., Faheem, S.A., Lesch, D.A., Ozolinš, V.: A self-catalyzing hydrogen-storage material, Angew. Chem. Int. Ed. 47, 882–887 (2008)

Xiong, Z., Wu, G., Hu, J., Chen, P., Luo, W., Wang, J.: Investigations on hydrogen storage over Li–Mg–N–H complex—the effect of compositional changes. J. Alloys Compd. 417, 190–194 (2006)

Kang, X., Fang, Z., Kong, L., Cheng, H., Yao, X., Lu, G., Wang, P.: Ammonia borane destabilized by lithium hydride: an advanced on-board hydrogen storage material. Adv. Mater. 20, 2756–2759 (2008)

Shore, S.G., Parry, R.W.: The crystalline compound Ammonia-borane NH3BH3. J. Am. Chem. Soc. 77, 6084–6085 (1955)

Hu, M.G., Geanangel, R.A., Wendlandt, W.W.: The thermal decomposition of ammonia borane. Thermochim. Acta 23, 249–255 (1978)

He, T., Xiong, Z., Wu, G., Chu, H., Wu, C., Zhang, T., Chen, P.: Nanosized Co- and Ni-catalyzed ammonia borane for hydrogen storage. Chem. Mater. 21, 2315–2318 (2009)

Welchman, E., Thonhauser, T.: Lowering the hydrogen desorption temperature of NH3BH3 through B-group substitutions. J. Mater. Chem. A 36, 18528–18534 (2015)

Tao, J., Lv, N., Wen, L., Qi, Y., Lv, X.: Hydrogen-release mechanisms in LiNH2BH3·NH3BH3: a theoretical study. J. Mol. Struct. 1081, 437–442 (2014)

Chen, X., Yuan, F., Gu, Q., Yu, X.: Synthesis, structures and hydrogen storage properties of two new H-enriched compounds: Mg(BH4)2(NH3BH3)2 and Mg(BH4)2·(NH3)2(NH3BH3). Dalt. Trans. 42, 14365–14368 (2013)

Kantürk, Figen A., Pişkin, M.B., Coşkuner, B., Imamoǧlu, V.: Synthesis, structural characterization, and hydrolysis of Ammonia Borane (NH3BH3) as a hydrogen storage carrier. Int. J. Hydrogen Energy 38, 16215–16228 (2013)

Yang, Y.-W., Feng, G., Lu, Z.-H., Hu, N., Zhang, F., Chen, X.-S.: In situ synthesis of reduced graphene oxide supported co nanoparticles as efficient catalysts for hydrogen generation from NH3BH3. Wuli Huaxue Xuebao/Acta Phys. Chim. Sin. 30, 1180–1186 (2014)

Xiong, Z., Yong, C.K., Wu, G., Chen, P., Shaw, W., Karkamkar, A., Autrey, T., Jones, M.O., Johnson, S.R., Edwards, P.P., David, W.I.F.: High-capacity hydrogen storage in lithium and sodium amidoboranes. Nat Mater 7, 138–141 (2008)

Diyabalanage, H.V.K., Shrestha, R.P., Semelsberger, T.A., Scott, B.L., Bowden, M.E., Davis, B.L., Burrell, A.K.: Calcium amidotrihydroborate: a hydrogen storage material, Angew. Chem. Int. Ed. Engl. 46, 8995–8997 (2007)

Wu, H., Zhou, W., Yildirim, T.: Alkali and alkaline-earth metal amidoboranes: structure, crystal chemistry, and hydrogen storage properties. J. Am. Chem. Soc. 130, 14834–14839 (2008)

Reilly, J.J., Wiswall, R.H.: Reaction of hydrogen with alloys of magnesium and nickel and the formation of Mg2NiH4. Inorg. Chem. 7, 2254–2256 (1968)

Ghaani, M.R., Catti, M., Nale, A.: Thermodynamics of dehydrogenation of the 2LiBH4–Mg2FeH6 composite. J. Phys. Chem. C 116, 26694–26699 (2012)

Vajo, J.J., Skeith, S.L., Mertens, F.: Reversible storage of hydrogen in destabilized LiBH4. J. Phys. Chem. B 109, 3719–3722 (2005)

Nale, A., Catti, M., Bardají, E.G., Fichtner, M.: On the decomposition of the 0.6LiBH4–0.4 Mg(BH4)2 eutectic mixture for hydrogen storage. Int. J. Hydrogen Energy 36, 13676–13682 (2011)

Wu, C., Wu, G., Xiong, Z., David, W.I.F., Ryan, K.R., Jones, M.O., Edwards, P.P., Chu, H., Chen, P.: Stepwise phase transition in the formation of lithium amidoborane. Inorg. Chem. 49, 4319–4323 (2010)

Baitalow, F., Wolf, G., Grolier, J.-P.E., Dan, F., Randzio, S.L.: Thermal decomposition of ammonia–borane under pressures up to 600 bar. Thermochim. Acta 445, 121–125 (2006)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Ghaani, M.R., Catti, M. Dehydrogenation properties of the LiNH2BH3/MgH2 and LiNH2BH3/LiBH4 bi-component hydride systems for hydrogen storage applications. Mater Renew Sustain Energy 7, 26 (2018). https://doi.org/10.1007/s40243-018-0133-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40243-018-0133-9