Abstract

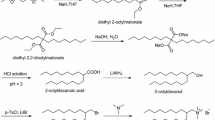

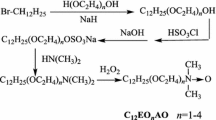

Novel Brönsted acid-surfactants with different alkyl chains were synthesized via a two-step process, and their surface properties were studied. The critical micelle concentration(cmc), surface tension at the cmc(γcmc), and ability of these compounds to lower the surface tension by 0.02 N/m(C20 and pC20) were investigated at 25 and 40 °C. The molecular architecture of the compounds strongly influenced these physicochemical parameters. The ability of these compounds to lower surface tension was found to be good. Etherification in microemulsions formed by these surfactants as well as dodecylbenzenesulfonic acid(DBSA) was performed; surfactants 3a and 3b were found to be much more efficient than DBSA.

Similar content being viewed by others

References

Domínguez R., Rodríguez A., Maestre A., Robina I., Moyá M. L., J. Colloid Inter. Sci., 2012, 386(1), 228

Mouraa E. F., Netoa A. O. W., Dantasa T. N., Júniora H. S., Gurgel A., Colloid. Surfaces A 2009, 340, 199

Chen J., Qiao M., Gao N., Ran Q., Wu S., Qi S., Colloid. Surface A 2017, 522, 593

Wang X., Li R., Li Z., Liu J., J. Colloid Inter. Sci., 2017, 505, 847

Manabe K., Limura S., Sun X.M., Kobayashi S., J. Am. Chem. Soc., 2002, 124, 11971

Limura S., Manabe K., Kobayashi S., Org. Lett. 2003, 5, 101

Jang H., Lee H., Colloid. Surfaces A 2018, 538, 574

Menger F. M., Elringtn A. R., J. Am. Chem. Soc., 1991, 113, 9621

Yin J. C., Chen Y. K., Jiang J. Z., Cui Z. G., Chem. J. Chinese Universities, 2017, 38(9), 1645

Liu X., Xing X., Gao Z., Colloid. Surfaces A 2014, 457, 374

Dong D., Ouyang Y., Yu H., Liu Q., Liu J., Wang M., Zhu J., J. Org. Chem., 2005, 70, 4535

Fernando Silva O., de Rossia Rita H., Mariano Correa N., RSC Adv. 2015, 5, 34878

Jing L., Li X., Han Y., Chu Y., Colloid. Surface A 2008, 326, 37

Han Y., Chu Y., J. Mol. Catal. A: Chem., 2005, 273, 232

Song K., Chu Y., Dong L., Song J., Wang D., J. Mol. Catal. A: Chem., 2008, 282, 144

Malferrari D., Armenise N., Decessari S., Galletti P., Tagliavini E., ACS Sustain Chem. Eng., 2015, 3, 1579

Wang X., Yan F., Li Z., Zhang L., Zhao S., An J., Yu J., Colloid. Surfaces A 2007, 302, 532

You A., Cao Y., Cao G., Chem. Res. Chinese Universities 2017, 33(4), 525

Author information

Authors and Affiliations

Corresponding authors

Additional information

Supported by the National Natural Science Foundation of China(No. 51373067).

Rights and permissions

About this article

Cite this article

Yang, M., Wei, Z., Duan, H. et al. Surface Properties and Etherification in Microemulsion Systems of Novel Brönsted Acid Surfactants. Chem. Res. Chin. Univ. 34, 440–443 (2018). https://doi.org/10.1007/s40242-018-8046-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40242-018-8046-9