Abstract

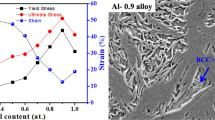

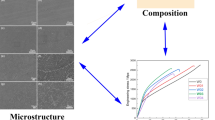

A series of AlxCrFe2Ni2Mo0.2 alloy consisting of FCC + BCC phases have been designed, and their as-cast microstructures and mechanical properties were also investigated with x ranging from 0.6 to 0.9. It was found that with the addition of Al element, the solidified structures changed from dendrite to columnar crystal then back to dendrite again. Moreover, the increased amount of BCC phase resulted in finer and more uniform microstructures of FCC [FeCrNi(Mo)] and BCC (Al–Ni) phases. Tensile yield strength and hardness of alloys showed a similar increasing trend as the volume fraction of BCC phase increased. Both strain hardening rate and strain hardening exponent were calculated to assess the tensile properties of the alloys. It was shown that Al0.6CrFe2Ni2Mo0.2 exhibited the most excellent and comprehensive mechanical properties due to its high work hardening ability and stable strain hardening rate. The product of strength and elongation of Al0.6CrFe2Ni2Mo0.2 reached up to 38.6 GPa%, which was higher than most of the reported as-cast high-entropy alloys.

Similar content being viewed by others

References

ASM, ASM Handbook, Vol. 1: Alloy Phase Diagrams, 10th edn. (ASM International, Materials Park, 1992), p. 949

D.B. Miracle, O.N. Senkov, Acta Mater. 122, 448 (2017)

A.L. Greer, Nature 366, 303 (1993)

W.R. Wang, W.L. Wang, S.C. Wang, Y.C. Tsai, C.H. Lai, J.W. Yeh, Intermetallics 26, 44 (2012)

Y.P. Cai, G.J. Wang, Y.J. Ma, Z.H. Cao, X.K. Meng, Scr. Mater. 162, 281 (2019)

A. Verma, P. Tarate, A.C. Abhyankar, M.R. Mohape, D.S. Gowtam, V.P. Deshmukh, T. Shanmugasundaram, Scr. Mater. 161, 21 (2019)

S.J. Zheng, Z.B. Cai, J.B. Pu, C. Zeng, S.Y. Chen, R. Chen, L.P. Wang, Appl. Surf. Sci. 483, 870 (2019)

H.M. Daoud, A.M. Manzoni, N. Wanderka, U. Glatzel, JOM 67, 2271 (2015)

C. Xiang, Z.M. Zhang, H.M. Fu, E.H. Han, J.Q. Wang, H.F. Zhang, G.D. Hu, Acta Metall. Sin. (Engl. Lett.) 32, 1053 (2019)

Y.X. Zhuang, X.L. Zhang, X.Y. Gu, J. Alloys Compd. 743, 514 (2018)

J.Y. He, W.H. Liu, H. Wang, Y. Wu, X.J. Liu, T.G. Nieh, Z.P. Lu, Acta Mater. 62, 105 (2014)

K.B. Zhang, Z.Y. Fu, Intermetallics 22, 24 (2012)

S.G. Ma, Y. Zhang, Mater. Sci. Eng. A 532, 480 (2012)

Y. Dong, Y.P. Lu, J.R. Kong, J.J. Zhang, T.J. Li, J. Alloys Compd. 573, 96 (2013)

J.M. Zhu, H.M. Fu, H.F. Zhang, A.M. Wang, H. Li, Z.Q. Hua, Mater. Sci. Eng. A 527, 6975 (2010)

T.T. Shun, L.Y. Chang, M.H. Shiu, Mater. Charact. 70, 63 (2012)

J.M. Zhu, H.F. Zhang, H.M. Fu, A.M. Wang, H. Li, Z.Q. Hu, J. Alloys Compd. 497, 52 (2010)

S. Guo, C.T. Liu, Prog. Nat. Sci. Mater. Int. 21, 434 (2011)

Y. Dong, Dissertation, Dalian University of Technology, 2016 (in Chinese)

L. Wang, J. Shen, Z. Shang, H.Z. Fu, Scr. Mater. 89, 2 (2014)

L. Wang, C.L. Yao, J. Shen, Y.P. Zhang, T. Wang, H.X. Xu, L.H. Gao, G.J. Zhang, Mater. Sci. Eng. A 744, 596 (2019)

D.G. Lee, S. Lee, Y.T. Lee, Mater. Sci. Eng. A 486, 21 (2008)

J.R. Yang, L.C. Chang, Mater. Sci. Eng. A 223, 158 (1997)

Y. Ma, Q. Wang, B.B. Jiang, C.L. Li, J.M. Hao, X.N. Li, C. Dong, T.G. Nieh, Acta Mater. 147, 217 (2018)

Z.Y. Rao, X. Wang, J. Zhu, X.H. Chen, L. Wang, J.J. Si, Y.D. Wu, X.D. Hui, Intermetallics 77, 23 (2016)

B. Cai, B. Liu, S. Kabra, Y.Q. Wang, K. Yan, P.D. Lee, Y. Liu, Acta Mater. 127, 471 (2017)

W.H. Liu, Z.P. Lu, J.Y. He, J.H. Luan, Z.J. Wang, B. Liu, Y. Liu, M.W. Chen, C.T. Liu, Acta Mater. 116, 332 (2016)

X.Z. Gao, Y.P. Lu, B. Zhang, N.N. Liang, G.Z. Wu, G. Sha, J.Z. Liu, Y.H. Zhao, Acta Mater. 141, 59 (2017)

T. Xu, Y. Feng, Z. Jin, S. Song, D. Wang, Mater. Sci. Eng. A 550, 80 (2012)

Q. Li, T.W. Zhang, J.W. Qiao, S.G. Ma, D. Zhao, P. Lu, B. Xu, Z.H. Wang, Mater. Sci. Eng. A 767, 138424–138426 (2019)

M.V. Klimova, A.O. Semenyuk, D.G. Shaysultanov, G.A. Salishchev, S.V. Zherebtsov, N.D. Stepanov, J. Alloys Compd. 811, 15200–15206 (2019)

Z.R. Pei, Mater. Sci. Eng. A 737, 132 (2018)

W.Y. Huo, H. Zhou, F. Fang, X.J. Hu, Z.H. Xie, J.Q. Jiang, Mater. Sci. Eng. A 689, 368 (2017)

K. Rajan, J.B. Sande, J. Mater. Sci. 17, 769 (1982)

K. Rajan, Metall. Trans. A 13, 1161 (1982)

Y. Dong, X.X. Gao, Y.P. Lu, T.M. Wang, T.J. Li, Mater. Lett. 169, 62 (2016)

W.H. Liu, J.Y. He, H.L. Huang, H. Wang, Z.P. Lu, C.T. Liu, Intermetallics 60, 1 (2015)

S.G. Ma, S.F. Zhang, J.W. Qiao, Z.H. Wang, M.C. Gao, Z.M. Jiao, H.J. Yang, Y. Zhang, Intermetallics 54, 104 (2014)

G.A. Salishchev, M.A. Tikhonovsky, D.G. Shaysultanov, N.D. Stepanov, A.V. Kuznetsov, I.V. Kolodiy, A.S. Tortika, O.N. Senkov, J. Alloys Compd. 591, 11 (2014)

C. Ng, S. Guo, J.H. Luan, Q. Wang, J. Lu, S.Q. Shi, C.T. Liu, J. Alloys Compd. 584, 530 (2014)

S.Z. Niu, H.C. Kou, T. Guo, Y. Zhang, J. Wang, J.S. Li, Mater. Sci. Eng. A 671, 82 (2016)

T.T. Zou, S.B. Ren, P.K. Liaw, Y. Zhang, Int. J. Miner. Metall. Mater. 20, 549 (2013)

X. Jin, Y.X. Liang, L. Zhang, J. Bi, Y. Zhou, B.S. Li, Mater. Sci. Eng. A 745, 137 (2019)

N.D. Stepanov, N.Y. Yurchenko, M.A. Tikhonovsky, G.A. Salishchev, J. Alloys Compd. 687, 59 (2016)

Acknowledgements

This work was financially supported by the National Key Research and Development Program of China (No. 2017YFA0403803) and the National Natural Science Foundation of China (Nos. 51771041 and 51901116).

Author information

Authors and Affiliations

Corresponding author

Additional information

Available online at http://link.springer.com/journal/40195.

Rights and permissions

About this article

Cite this article

Nie, Q., Liang, H., Qiao, D. et al. Microstructures and Mechanical Properties of Multi-component AlxCrFe2Ni2Mo0.2 High-Entropy Alloys. Acta Metall. Sin. (Engl. Lett.) 33, 1135–1144 (2020). https://doi.org/10.1007/s40195-020-01085-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-020-01085-1