Abstract

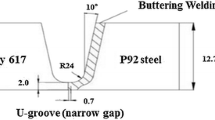

The residual stress evolution in a safe-end/nozzle dissimilar metal welded joint of CAP1400 nuclear power plants was investigated in the manufacturing process by finite element simulation. A finite element model, including cladding, buttering, post-weld heat treatment (PWHT) and dissimilar metal multi-pass welding, is developed based on SYSWELD software to investigate the evolution of residual stress in the aforementioned manufacturing process. The results reveal a large tensile axial residual stress, which exists at the weld zone on the inner surface, leads to a high sensitivity to stress corrosion cracking (SCC). PWHT process before dissimilar metal multi-pass welding process has a great influence on the magnitude and distribution of final axial residual stress. The risk of SCC on the inner surface of the pipe will increase if PWHT process is not taken into account. Therefore, such crucial thermal manufacturing process such as cladding, buttering and post-weld heat treatment, besides the multi-pass welding process, should be considered in the numerical model in order to accurately predict the distribution and the magnitude of the residual stress.

Similar content being viewed by others

References

P. Dong, F.W. Brust, J. Press. Vessel Technol. 122, 329 (2000)

E.H. Han, Acta Metall. Sin. 47, 769 (2011). (in Chinese)

H.L. Ming, Z.M. Zhang, J.Q. Wang, E.H. Han, M.X. Su, Acta Metall. Sin. 53, 57 (2017). (in Chinese)

H.T. Wang, G.Z. Wang, F.Z. Xuan, S.T. Tu, Nucl. Eng. Des. 241, 3234 (2011)

O. Muránsky, M.C. Smith, P.J. Bendeich, L. Edwards, Comput. Mater. Sci. 50, 2203 (2011)

S. Ghosh, V.P.S. Rana, V. Kain, V. Mittal, S.K. Baveja, Mater. Des. 32, 3823 (2011)

J. Katsuyama, M. Udagawa, H. Nishikawa, M. Nakamura, K. Onizawa, E-J Adv. Maint. 2, 50 (2010)

T.K. Song, H.R. Bae, Y.J. Kim, K.S. Lee, Fatigue Fract. Eng. Mater. Struct. 33, 689 (2010)

T.K. Song, Y.B. Kim, Y.J. Kim, C.Y. Oh, Proc. Mater. Sci. 3, 784 (2014)

T.K. Song, C.Y. Oh, J.S. Kim, Y.J. Kim, K.S. Lee, C.Y. Park, Eng. Fract. Mech. 78, 1957 (2011)

E.M. Dehaghi, H. Moshayedi, I. Sattari-Far, A.F. Arezoodar, Int. J. Press. Vessels Pip. 152, 56 (2017)

P.J. Bendeich, O. Muránsky, C.J. Hamelin, M.C. Smith, L. Edwards, Comput. Mater. Sci. 62, 285 (2012)

A. Joseph, S.K. Rai, T. Jayakumar, N. Murugan, Int. J. Press. Vessels Pip. 82, 700 (2005)

P. Dong, J.K. Hong, P.J. Bouchard, Int. J. Press. Vessels Pip. 82, 258 (2005)

T.P.T. Soanes, W. Bell, A.J. Vibert, Int. J. Press. Vessels Pip. 82, 311 (2005)

D.A. Deng, K. Ogawa, S. Kiyoshima, N. Yanagida, K. Saito, Comput. Mater. Sci. 47, 398 (2009)

S. Courtin, X. Ficquet, T.T.T. Le, P. Gilles, M. Yescas, in Proceedings of the ASME 2012 Pressure Vessels and Piping Conference, Toronto, Ontario, Canada, 15–19 July 2012

O. Doyen, D. Ayrault, A. Bonaventure, Weld. World 7, 1 (2015)

D.-J. Shim, S. Kalyanam, F. Brust, G. Wilkowski, M. Smith, A. Goodfellow, J. Press. Vessel Technol. 134, 051402-1 (2012)

A. Yaghi, T.H. Hyde, A.A. Becker, W. Sun, J.A. Williams, Int. J. Press. Vessels Pip. 83, 864 (2006)

J. Katsuyama, H. Nishikawa, M. Udagawa, M. Nakmura, K. Onizawa, J. Press. Vessel Technol. 135, 051402-1 (2013)

Q. Wang, X.S. Liu, P. Wang, X. Xiong, H.Y. Fang, J. Mater. Process. Technol. 240, 77 (2017)

S. Li, S.D. Ren, Y.B. Zhang, D. Deng, H. Murakawa, J. Mater. Process. Technol. 244, 240 (2017)

J. Goldak, A. Chakravarti, M. Bibby, Metall. Trans. B 15, 299 (1984)

ESI Group, Material Database for SYSWELD 2010 (ESI France, Paris, 2009)

Acknowledgements

This work was supported by the Open-ended Fund of the CAS Key Laboratory of Nuclear Materials and Safety Assessment (Grant No. 2015NMSAKF02).

Author information

Authors and Affiliations

Corresponding author

Additional information

Available online at http://link.springer.com/journal/40195

Rights and permissions

About this article

Cite this article

Dong, WC., Gao, DB. & Lu, SP. Numerical Investigation on Residual Stresses of the Safe-End/Nozzle Dissimilar Metal Welded Joint in CAP1400 Nuclear Power Plants. Acta Metall. Sin. (Engl. Lett.) 32, 618–628 (2019). https://doi.org/10.1007/s40195-018-0803-8

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-018-0803-8