Abstract

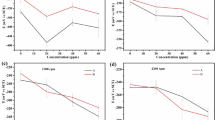

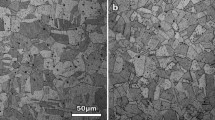

The composition and structural evolution of the corrosion product film of two commercial 90Cu–10Ni tubes, namely Tube A and Tube B, after being immersed in natural seawater for 1, 3, and 6 months were characterized by scanning electron microscopy, energy-dispersive X-ray spectroscopy, X-ray diffraction, and X-ray photoelectron spectroscopy, and its effect on the erosion–corrosion behavior of the tubes was determined through a rotating cylinder electrode system using various electrochemical techniques. For the freshly polished samples used as contrast samples, the flow velocity mainly enhanced the cathodic reaction at low flow velocities while both the anodic and the cathodic reactions were remarkably accelerated at higher flow velocities. The corrosion product films formed on the two commercial 90Cu–10Ni tubes after being immersed in seawater for up to 6 months are of a complex three-layer or multilayer structure. The structural evolution of the films is out of sync for the two tubes. A continuous residual substrate layer depleted of Ni was observed in the inner layer of the films on Tube B after 30, 90, and 180 days’ immersion, while it was observed in the film on Tube A only after 180 days’ immersion. The nature of the inner layer plays a crucial role in the erosion–corrosion resistance of the 90Cu–10Ni tubes at higher flow velocity. The film with a compact and continuous inner layer of Cu2O doped with Ni2+ and Ni3+ which bonds firmly with the substrate could survive and even get repaired with the increased flow velocity. The film on Tube B possessing a hollow and discontinuous inner layer composed of the residual substrate was degraded rapidly with increasing rotation speed in spite of its quite good resistance at the stagnant or lower speed conditions.

Similar content being viewed by others

References

F. Mansfeld, G. Liu, H. Xiao, C.H. Tsai, B.J. Little, Corros. Sci. 36, 2063 (1994)

W. Schleich, Typical Failures of CuNi 90/10 Seawater Tubing Systems and How to Avoid Them. In: Eurocorr, NACE. 1 (2004)

S. Colin, E. Beche, R. Berjoan, H. Jolibois, A. Chambaudet, Corros. Sci. 41, 1051 (1999)

K.D. Efird, Corrosion 31, 77 (1975)

G. Kear, B.D. Barker, K. Stokes, F.C. Walsh, J. Appl. Electrochem. 34, 659 (2004)

R.F. North, M.J. Pryor, Corros. Sci. 10, 297 (1970)

W.B. Brooks, Corrosion 24, 171 (1968)

A.M. Beccaria, J. Crousier, Br. Corros. J. 26, 5 (1991)

A. Ma, S. Jiang, Y. Zheng, Z. Yao, W. Ke, Acta Metall. Sin. (Engl. Lett.) 27, 730 (2014)

A.M. Beccaria, G. Poggi, P. Traverso, M. Ghiazza, Corros. Sci. 32, 1263 (1991)

F.K. Crundwell, Electrochim. Acta 36, 2135 (1991)

A.L. Ma, S.L. Jiang, Y.G. Zheng, W. Ke, Corros. Sci. 91, 245 (2015)

S.R. Allahkaram, P. Zakersafaee, S.A.M. Haghgoo, Eng. Fail. Anal. 18, 1108 (2011)

K. Chandra, V. Kain, G.K. Dey, P.S. Shetty, R. Kishan, Eng. Fail. Anal. 17, 587 (2010)

O. Elragei, F. Elshawesh, H.M. Ezuber, Desalin. Water Treat. 21, 17 (2010)

B.C. Syrett, Corrosion 32, 242 (1976)

M. Metikoš-Huković, I. Škugor, Z. Grubač, R. Babić, Electrochim. Acta 55, 3123 (2010)

T. Hodgkiess, G. Vassiliou, Desalination 183, 235 (2005)

M.S. Parvizi, A.A. Aladjem, J.E. Castle, Int. Mater. Rev. 33, 169 (1988)

C.A. Powell, H.T. Michels, Copper–nickel alloys for seawater corrosion resistance and anti-fouling—a state of the art review. In: Paper Presented at the Conference of Corrosion NACE International, Orlando, Florida, 26–31 March 2000

J.R. Macdonald, Impedance Spectroscopy: Emphasizing Solid Materials and Systems (Wiley, New York, 1987)

S.A. Campbell, G.J.W. Radford, C.D.S. Tuck, B.D. Barker, Corrosion 58, 57 (2002)

W.A. Badawy, K.M. Ismail, A.M. Fathi, Electrochim. Acta 50, 3603 (2005)

P.K. Chauhan, H.S. Gadiyar, Corros. Sci. 25, 55 (1985)

L. Babouri, K. Belmokre, A. Abdelouas, J.F. Bardeau, Y. El Mendili, Int. J. Electrochem. Sci. 10, 7818 (2015)

B. Sun, T.Y. Ye, Q. Feng, J.H. Yao, M. Wei, Mater. Des. 8, 6029 (2015)

G. Kear, B.D. Barker, K.R. Stokes, F.C. Walsh, Electrochim. Acta 52, 1889 (2007)

R.J.K. Wood, S.P. Hutton, D.J. Schiffrin, Corros. Sci. 30, 1177 (1990)

A.M. Naguib, Port. Electrochim. Acta 22, 301 (2005)

Z.B. Zheng, Y.G. Zheng, X. Zhou, S.Y. He, W.H. Sun, J.Q. Wang, Corros. Sci. 88, 187 (2014)

A. Neville, M. Reyes, T. Hodgkiess, A. Gledhill, Wear 238, 138 (2000)

K. Sasaki, G.T. Burstein, Corros. Sci. 49, 92 (2007)

G.D. Bengough, R.M. Jones, R. Pirret, J. Inst. Met. 23, 65 (1920)

S.J. Yuan, S.O. Pehkonen, Corros. Sci. 49, 1276 (2007)

P. Druska, H.H. Strehblow, Corros. Sci. 38, 1369 (1996)

R.C.N. Liberto, R. Magnabosco, N. Alonso-Falleiros, Corros. Sci. 53, 1976 (2011)

O.O. Ekerenam, A. Ma, Y. Zheng, W. Emori, J. Mater. Eng. Perform. 26, 1701 (2017)

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (Grant No. 51601200) and the National Environmental Corrosion Platform (No. 2005DKA10400).

Author information

Authors and Affiliations

Corresponding author

Additional information

Available online at http://link.springer.com/journal/40195

Rights and permissions

About this article

Cite this article

Ekerenam, O.O., Ma, AL., Zheng, YG. et al. Evolution of the Corrosion Product Film and Its Effect on the Erosion–Corrosion Behavior of Two Commercial 90Cu–10Ni Tubes in Seawater. Acta Metall. Sin. (Engl. Lett.) 31, 1148–1170 (2018). https://doi.org/10.1007/s40195-018-0745-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-018-0745-1