Abstract

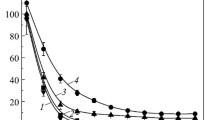

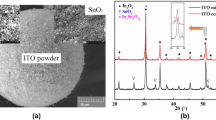

Effect of trace O element on the high-temperature wettability between Ni3Al scrap melt and Y2O3 ceramic at 1873 K is investigated. With the increase in O content in Ni3Al scrap melt from 6 to 21 ppm, the equilibrium contact angle decreases from 93.3° to 88.9°. The initial surface tension and adhesive work of molten Ni3Al scrap drop from 3153.5 to 807.4 mN m−1 and from 2974.6 to 882.2 mN m−1, respectively. The average spreading rate increases from 0.03° s−1 to 0.17° s−1. The whole wetting processes are divided into four periods. The main driving force for spreading in period (1) is the adsorption and diffusion of active atoms around the interface. Trace O content in Ni3Al scrap has a significant impact on interfacial reactions which mostly take place in the second stage, and can accelerate the spreading process on Y2O3 substrate. The reaction products during wetting process are Y3Al5O12, YAlO3 and Al2O3.

Similar content being viewed by others

References

W.Y. Zhao, Y.Z. Liu, S.S. Li, S.K. Gong, Oxid. Met. 81, 631 (2014)

X.H. Zhao, Z.H. Huang, Y.N. Tan, Q. Zhang, Y.U. Qian, H.B. Xu, J. Aeronaut. Mater. 26, 20 (2006). (in Chinese)

N.V. Kazantseva, B.A. Greenberg, E.V. Shorokhov, A.N. Pirogov, Y.A. Dorofeev, Phys. Met. Metall. 99, 535 (2005)

Y. Cheng, H. Zhang, L.W. Song, Y. Ma, S.S. Li, S.K. Gong, Chin. J. Nonferrous Met. 22, 510 (2012)

Y.W. Zhang, F.M. Wang, B.F. Hu, Acta Metall. Sin. 48, 1011 (2012). (in Chinese)

G.A. Rao, M. Srinivas, D.S. Sarma, Mater. Sci. Eng. A 435, 84 (2006)

C.F. Chai, Y.Q. Yang, Y.H. Zhang, Acta Metall. Sin. (Engl. Lett.) 21, 220 (2008)

A. Kostov, B. Friedrich, Comput. Mater. Sci. 38, 374 (2007)

K. Sakamoto, K. Yoshikawa, T. Kusamichi, T. Onoye, ISIJ Int. 32, 616 (1992)

J. Barbosa, H. Puga, C.S. Ribeiro, O.M.N.D. Teodoro, A.C. Monteiro, Int. J. Cast Met. Res. 19, 331 (2006)

T. Tetsui, T. Kobayashi, T. Ueno, H. Harada, Intermetallics 31, 274 (2012)

H.R. Zhang, X.X. Tang, C.G. Zhou, H. Zhang, S.W. Zhang, J. Eur. Ceram. Soc. 33, 925 (2013)

M. Gao, L.N. Jia, X.X. Tang, R.J. Cui, H. Zhang, China Foundry 08, 190 (2011)

C. Ran, H.R. Zhang, H. Zhang, B.B. Wan, P. Bai, Acta Metall. Sin. (Engl. Lett.) 5, 1 (2017)

D. Matthias, N. Achim, K.P. Trumble, R. Jürgen, J. Am. Ceram. Soc. 82, 2825 (1999)

M.L. Muolo, F. Valenza, A. Passerone, D. Passerone, Mater. Sci. Eng. A 495, 153 (2008)

O. Dezellus, F. Hodaj, N. Eustathopoulos, Acta Mater. 50, 4741 (2002)

I.A. Aksay, C.E. Hoge, J.A. Pask, J. Phys. Chem. 78, 12 (1974)

E. Saiz, A.P. Tomsia, Curr. Opin. Solid State Mater. Sci. 9, 167 (2006)

E. Saiz, R.M. Cannon, A.P. Tomsia, Acta Mater. 48, 4449 (2000)

C.J. Xuan, Z. Zhao, P.G. Jönsson, J. Eur. Ceram. Soc. 36, 2435 (2016)

V. Naidich, K. Rasplavakh, A. Naukukra. SSP Naukova Dumka Kiev (1972) (in Russian)

K. Ogino, A. Adachi, K. Nogi, Tetsu-to-Hagané 59, 1237 (1973)

F. Valenza, M.L. Muolo, A. Passerone, J. Mater. Sci. 45, 2071 (2010)

S. Barzilai, M. Aizenshtein, N. Froumin, N. Frage, Mater. Sci. Eng. A 420, 291 (2006)

H. Yasuda, I. Ohnaka, Y. Mizutani, Y. Waku, Sci. Technol. Adv. Mater. 2, 67 (2001)

B. Cockayne, J. Less Commun. Met. 114, 199 (1985)

J.L. Caslavsky, D.J. Viechnicki, J. Mater. Sci. 15, 1709 (1980)

M.L. Muolo, F. Valenza, A. Passerone, D. Passerone, Mater. Sci. Eng. A 495, 153 (2008)

D. Chatain, F. Chabert, V. Ghetta, J. Fouletier, J. Am. Ceram. Soc. 76, 1568 (2010)

N. Eustathopoulos, Acta Mater. 46, 2319 (1998)

Acknowledgements

This work was supported financially by the National Science & Technology Pillar Program of China (No. 2013BAB11B04) and the National Natural Science Foundation of China (No. 51404017). Furthermore, the authors wish to express their appreciations to the State Key Laboratory of Refractories and Metallurgy, Wuhan University of Science and Technology and the group of Prof. Ping Shen of Jilin University for the help of the wetting experiments.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Available online at http://link.springer.com/journal/40195

Rights and permissions

About this article

Cite this article

Bai, P., Zhang, HR., Wan, BB. et al. Effect of Trace O Element on High-temperature Wettability Between Ni3Al Melt and Y2O3 Ceramic. Acta Metall. Sin. (Engl. Lett.) 31, 552–560 (2018). https://doi.org/10.1007/s40195-017-0679-z

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-017-0679-z