Abstract

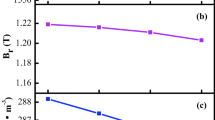

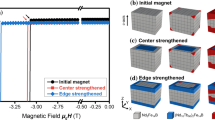

In this paper, the grain boundary diffusion process (GBDP) using a Dy70Cu30 (at.%) alloy as the diffusion source was performed in a commercial sintered Nd–Fe–B magnet, and the effect of heat treatment time on the microstructure and magnetic properties of the magnet was investigated in detail. For the processed magnets heat-treated at 860 °C, as heat treatment time increased, the coercivity and the depth of (Nd,Dy)2Fe14B core–shell structure increased first and then decreased. However, when the heat treatment time was more than 2 h, the diffusion path of Dy from the Dy-rich shell phase into the Nd2Fe14B grains was revealed, and a nearly homogeneous (Nd,Dy)2Fe14B phase was formed, which brought on the decrease in both the depth of visible core–shell structure and the coercivity of Nd–Fe–B magnet.

Similar content being viewed by others

References

J.J. Croat, J.F. Herbst, R.W. Lee, F.E. Pinkerton, J. Appl. Phys. 55, 2078 (1984)

M. Sagawa, S. Fujimura, N. Togawa, H. Yamamoto, Y. Matsuura, J. Appl. Phys. 55, 2083 (1984)

H. Sepehri-Amin, T. Ohkubo, K. Hono, J. Appl. Phys. 107, 09A745 (2010)

H. Sepehri-Amin, T. Ohkubo, K. Hono, Acta Mater. 61, 1982 (2013)

Z. Samardžija, P. McGuiness, M. Soderžnik, S. Kobe, M. Sagawa, Mater. Charact. 67, 27 (2012)

K. Hirota, T. Hirota, M. Minowa, J. Honshima, J. Alloys Compd. 42, 2909 (2006)

F. Xu, J. Wang, X. Dong, L. Zhang, J.J. Wu, J. Alloys Compd. 509, 7909 (2011)

M. Soderžnik, M. Korent, K. Žagar Soderžnik, M. Katter, K. Üstüner, S. Kobe, Acta Mater. 115, 278 (2016)

K.H. Bae, S.R. Lee, H.J. Kim, M.W. Lee, T.S. Jang, J. Appl. Phys. 118, 203902 (2015)

T. Ma, X. Wang, X. Liu, C. Wu, M. Yan, J. Phys. D Appl. Phys. 48, 215001 (2015)

S. Lee, J. Kwon, H.R. Cha, K.M. Kim, H.W. Kwon, J. Lee, D. Lee, Met. Mater. Int. 22, 340 (2016)

M. Tang, X. Bao, K. Lu, L. Sun, J. Li, X. Gao, Scr. Mater. 117, 60 (2016)

H. Sepehri-Amin, J. Liu, T. Ohkubo, K. Hioki, A. Hattori, K. Hono, Scr. Mater. 69, 647 (2013)

H. Sepehri-Amin, T. Ohkubo, S. Nagashima, M. Yano, T. Shoji, A. Kato, T. Schrefl, K. Hono, Acta Mater. 61, 6622 (2013)

X. Tang, R.J. Chen, W.Z. Yin, C.X. Jin, D. Lee, A. Yan, Appl. Phys. Lett. 107, 202403 (2015)

N. Watanabe, M. Itakura, M. Nishida, J. Alloys Compd. 557, 1 (2013)

Z. Wang, J. Ju, J. Wang, W. Yin, R. Chen, M. Li, C. Jin, X. Tang, D. Lee, A. Yan, Sci. Rep. 6, 38335 (2016)

S. Sawatzki, C. Kübel, S. Ener, O. Gutfleisch, Acta Mater. 115, 354 (2016)

M.J. Donahue, D.G. Porter, in OOMMF user’s guide, version 1.0, Nat. Inst. Standards and Technology, Gaithersburg, MD, Tech. Rep. NISTIR 6376. USA, 1999

M. Sagawa, S. Fujimura, H. Yamamoto, Y. Matsuura, S. Hirosawa, J. Appl. Phys. 57, 4094 (1985)

S. Hirosawa, Y. Matsuura, H. Yamamoto, S. Fujimura, M. Sagawa, H. Yamauchi, J. Appl. Phys. 59, 873 (1986)

N. Oono, M. Sagawa, R. Kasada, H. Matsui, A. Kimura, J. Magn. Magn. Mater. 323, 297 (2011)

K. Löewe, C. Brombacher, M. Katter, O. Gutfleisch, Acta Mater. 83, 248 (2015)

L.Q. Yu, J. Zhang, S.Q. Hu, Z.D. Han, M. Yan, J. Magn. Magn. Mater. 320, 1427 (2008)

M. Yan, L.Q. Yu, W. Luo, W. Wang, W.Y. Zhang, Y.H. Wen, J. Magn. Magn. Mater. 301, 1 (2006)

L. Liu, H. Sepehri-Amin, T. Ohkubo, M. Yano, A. Kato, T. Shoji, K. Hono, J. Alloys Compd. 666, 432 (2016)

Y.H. Liu, S. Guo, R.J. Chen, D. Lee, A. Yan, IEEE Trans. Magn. 47, 3270 (2011)

K. Skotnicová, G.S. Burkhanov, Y. Koshkidko, D. Růžička, T. Čegan, J. Ćwik, N.B. Kolchugina, A.A. Lukin, O. Životský, K. Hrabovská, Metalurgija 55, 621 (2016)

W.B. Cui, Y.Q. Fu, T. Liu, G.J. Li, Q. Wang, J. Alloys Compd. 686, 101 (2016)

K. Loewe, D. Benke, C. Kübel, T. Lienig, K.P. Skokov, O. Gutfleisch, Acta Mater. 124, 421 (2017)

Acknowledgements

This work was supported by the Guangdong Natural Science Foundation (2016A030313502), the Fundamental Research Funds for the Central Universities, SCUT (2015ZZ066), the Guangdong Science and Technology Planning Project (2013B090500115), and the Open Research Fund of Guangdong Key Laboratory (B7140010). We also thank Dr. Eric J. Payton (AFRL/RXCM) for proofreading this manuscript.

Author information

Authors and Affiliations

Corresponding author

Additional information

Available online at http://link.springer.com/journal/40195

Rights and permissions

About this article

Cite this article

Liu, H.Y., Wang, G., Hong, Y. et al. Effect of Heat Treatment Time on Dy–Cu Alloy Diffusion Process in Dy-Containing Commercial Nd–Fe–B Sintered Magnets. Acta Metall. Sin. (Engl. Lett.) 31, 496–502 (2018). https://doi.org/10.1007/s40195-017-0660-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-017-0660-x