Abstract

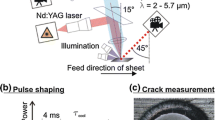

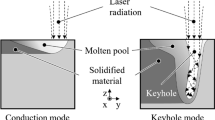

The weldability of materials is still for many years a highly contentious issue, particularly regarding the causes of the hot crack formation. Because of the process-related temperature and emissions, direct measurement for the arising strain in the close vicinity of the welding process is challenged. Therefore, the externally loaded hot cracking tests remain for decades the only way to determine the critical straining conditions for solidification cracking. In this study, a novel 2D in situ observation technique has been developed to analyze the strain evaluation during the welding process in the moment of crack formation. For the first time, the employed technique enabled the in situ measurement of the transient strain field at the surface of the workpiece directed to the laser beam in the critical range, where the solidification cracking normally occurs. Thus, the critical threshold strain values at high temperatures characterizing transition from crack-free to crack-concomitant welding process could be deduced. The influence of the global straining conditions on the direct local measured strain and strain rate for the stainless steel 316 L has been analyzed and discussed.

Similar content being viewed by others

References

Cross CE (2005) On the origin of weld solidification cracking. In: Hot cracking phenomena in welds, pp 3–18

Pellini WS (1952) Strain theory of hot tearing. Foundry 80:125–199

W. R. Apblett and W. S. Pellini, Factors which influence weld hot cracking. Welding Research Supplement, vol.: 33, pp. 83–90, 1954

Prokhorov NN (1968) Physical processes in metals during welding. Metallurgiya, Moscow:695

Prokhorov NN (1956) The problem of the strength of metals while solidifying during welding. Svarochnoe Proizvodstvo 6:5–11

U. Feurer, “Influence of alloy composition and solidification conditions on dendrite arm spacing, feeding and hot tearing properties of aluminium alloys,” in International Symposium on Engineering Alloys, 1977, pp. 131–145.

M. Rappaz, J.-M. Drezet, and M. Gremaud, “A new hot-tearing criterion,” Metallurgical and Materials Transactions A, vol. 30, no. 2, pp. 449–455, 1999

Senda T, Matsuda F, Takano G (1973) Studies on solidification crack susceptibility for weld metals with trans-varestraint test. J Japan Weld Soc 42:48–56

C. E. Cross, N. Coniglio, E. M. Westin, and A. Gumenyuk, “Laser Weldability of Stainless Steel,” in Hot Cracking Phenomena in Welds III, T. Böllinghaus, J. Lippold, and C. E. Cross, Eds. Berlin, Heidelberg: Springer Berlin Heidelberg, 2011, pp. 131–144.U. Feurer, “Influence of alloy composition and solidification conditions on dendrite arm spacing, feeding and hot tearing properties of aluminium alloys,” in International Symposium on Engineering Alloys, 1977, pp. 131–145.

N. Coniglio and C. E. Cross, “Characterization of Solidification Path for Aluminium 6060 Weld Metal with Variable 4043 Filler Dilution,” Welding in the World, vol. 50, no. 11, pp. 14–23, Nov. 2006.

H. Heuser, “Value of Different Hot Cracking Tests for the Manufacturer of Filler Metals,” in Hot Cracking Phenomena in Welds, T. Böllinghaus and H. Herold, Eds. Berlin, Heidelberg: Springer Berlin Heidelberg, 2005, pp. 305–327.

Matsuda F, Nakagawa H, Nakata K, Kohmoto H, Honda Y (1983) Quantitative evaluation of solidification brittleness of weld metal during solidification by means of in-situ observation and measurement (report I) : development of the MISO technique (materials, metallurgy & weldability). Transactions of JWRI 12(1):65–72

Kannengiesser T, Boellinghaus T (2014) Hot cracking tests—an overview of present technologies and applications. Welding in the World 58(3):397–421

De Strycker M, Lava P (2011) Measuring welding deformations with the digital image correlation technique. Weld J

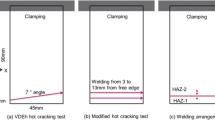

Quiroz V, Gumenyuk a, Rethmeier M (2012) Investigation of the hot cracking susceptibility of laser welds with the controlled tensile weldability test. The Journal of Strain Analysis for Engineering Design 47:587–599

Bakir N, Gumenyuk A, Rethmeier M (2016) Numerical simulation of solidification crack formation during laser beam welding of austenitic stainless steels under external load. Welding in the World 60(5):1001–1008

Bakir N, Gumenyuk A, and Rethmeier M (2014) Investigation of solidification cracking susceptibility in laser welded H400 austenitic stainless steel using digital image correlation technique, in SCT2014—future trends in steel development, processing technologies and applications - 4th International conference on steels in cars and trucks (Proceedings), pp. 299–307

Chen J, Yu X, Miller RG, Feng Z (2015) In situ strain and temperature measurement and modelling during arc welding. Sci Technol Weld Join 20(3):181–188

Gong X, Bansmer S, Strobach C, Unger R, Haupt M (2014) Deformation measurement of a birdlike airfoil with optical flow and numerical simulation. AIAA J 52(12):2807–2816

Bakir N, Gumenyuk A, Rethmeier M (2018) Investigation of solidification cracking susceptibility during laser beam welding using an in-situ observation technique. Sci Technol Weld Join 23(3):234–240

Baker S, Matthews I (2004) Lucas-Kanade 20 years on: a unifying framework. Int J Comput Vis 56(3):221–255

Lucas BD and Kanade T (1981) An iterative image registration technique with an application to stereo vision. International Joint Conference on Artificial Intelligence. Vacouver, pp. 674–679

Gong X, Bansmer S (2015) Horn-Schunck optical flow applied to deformation measurement of a birdlike airfoil. Chin J Aeronaut 28(5):1305–1315

Matsuda F, Nakagawa H, Tomita S (1987) Quantitative evaluation of solidification brittleness of weld metal during solidification by in-situ observation and measurement (report IV). Trans JWRI 16(2):85–95

Shinozaki K, Motomichi Y, Peng W, Tomoko T (2010) Prediction of occurrence of solidification cracking in weld metal. Weld Int 24(12):942–948

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended for publication by Commission IV - Power Beam Processes

Rights and permissions

About this article

Cite this article

Bakir, N., Pavlov, V., Zavjalov, S. et al. Development of a novel optical measurement technique to investigate the hot cracking susceptibility during laser beam welding. Weld World 63, 435–441 (2019). https://doi.org/10.1007/s40194-018-0665-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-018-0665-8