Abstract

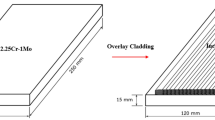

The weld interface of Alloy 625 clad onto AISI 8630 steel requires postweld heat treatment (PWHT) to reduce the heat-affected zone (HAZ) hardness of the steel to meet industry standards. This PWHT results in carbon diffusion and pile up in the transition zone at the fusion boundary which potentially embrittles the 8630/625 interface. For the 8630/625 overlay, the PWHT needs to be carefully selected to reduce the potential for hydrogen-assisted cracking (HAC) and/or sulfide stress cracking (SSC). In this work, a wide range of PWHT conditions defined by the Hollomon-Jaffe parameter (HJP) was studied using the delayed hydrogen cracking test (DHCT). The effect of PWHT on HAC behavior was quantified using this test and the optimal HJP range for resistance to HAC was determined to be in the range from 18,500 to 19,500. Fracture surface analysis was conducted on failed samples to further evaluate the effect of PWHT and confirm the optimal HJP range. The HAC behavior of the 8630/625 overlay was compared with that of the F22/625 overlay reported previously.

Similar content being viewed by others

References

Dai T, Lippold JC (2018) The effect of postweld heat treatment on hydrogen-assisted cracking of F22/alloy 625 overlays. Weld J 97:75s–90s

Dai T, and Lippold JC (2018) Tempering behavior of the fusion boundary region of alloy 625 weld overlay on 8630 steel—accepted. Welding in the World

ISO, 15156-2 (2009) Petroleum and natural gas industries—materials for use in H2S-containing environments in oil and gas production—part 2: cracking-resistant carbon and low alloy steels and the use of cast irons

Alexandrov BT, Lippold JC, Sowards JW, Hope AT, Saltzmann DR (2013) Fusion boundary microstructure evolution associated with embrittlement of Ni–base alloy overlays applied to carbon steel. Welding World 57:39–53

Alexandrov B, Shi S, Rodelas JM, Lippold JC (2012) A new test for evaluation of susceptibility to hydrogen assisted cracking in dissimilar metal welds. NACE corrosion conference & expo, Houston

Bourgeois D (2015) Hydrogen assisted crack in dissimilar metal welds for subsea service under cathodic protection: dissertation. The Ohio State University, Columbus

Wang M, Akiyama E, Tsuzaki K (2007) Effect of hydrogen on the fracture behavior of high strength steel during slow strain rate test. Corros Sci 49:4081–4097

Symons DM (1997) Hydrogen embrittlement of Ni-Cr-Fe alloys. Metall Mater Trans A 28A:655–663

Symons DM (1998) The effect of carbide precipitation on the hydrogen-enhanced fracture behavior of alloy 690. Metall Mater Trans A 29A:1265–1277

Fenske JA (2010) Microstructure and hydrogen induced failure mechanisms in iron-nickel weldments. University of Illinois at Urbana-Champaign, Urbana

Dodge MF (2014) The effect of heat treatment on the embrittlement of dissimilar welded joints. Univeristy of Leicester, Leicester

Luppo MI, Ovejero-Garcia J (1991) The influence of microstructure on the trapping and diffusion of hydrogen in a low carbon steel. Corros Sci 32(10):1125–1136

Nagao A, Smith CD, Dadfarnia M, Sofronis P, Robertson IM (2012) The role of hydrogen in hydrogen embrittlement fracture of lath martensitic steel. Acta Mater 60:5182–5189

Lippold JC (2014) Welding metallurgy and weldability. John Wiley & Sons, Inc, Hoboken p. 215

Gangloff RP, Somerday BP (2012) Gaseous hydrogen embrittlement of materials in energy technologies: volume 1. Woodhead Publishing, Cambridge

Lynch SP (1988) Environmentally assisted cracking: overview of evidence for an adsorption-induced localised-slip process. Acta Metallugica 36(10):2639–2661

Lynch SP (1989) Metallographic contributions to understanding mechanisms of environmentally assisted cracking. Metallography 23(2):147–171

Morlet J, Johnson H, Troiano A (1958) A new concept of hydrogen embrittlement in steel. J Iron Steel Inst 189:37–44

Troiano A (1960) The role of hydrogen and other interstitials in the mechanical behaviour of metals. Trans ASM 52:54–80

Whiteman M, Troiano A (1965) Hydrogen embrittlement of austenitic stainless steel. Corrosion 21(2):53–56

Oriani RA, Josephic PH (1979) Hydrogen-enhanced load relaxation in a deformed medium-carbon steel. Acta Metall 27(6):997–1005

Oriani R (1970) The diffusion and trapping of hydrogen in steel. Acta Metall 18:147–157

Wriedt HA, Oriani RA (1970) Effect of tensile and compressive elastic stress on equilibrium hydrogen solubility in a solid. Acta Metall 18:753–760

Oriani R (1972) A mechanistic theory of hydrogen embrittlement of steels. Berichte der Bunsengesellschaft für Phys Chemie 76:848–857

Oriani R, Josephic P (1974) Equilibrium aspects of hydrogen-induced cracking of steels. Acta Metall 22:1065–1074

Beachem C (1972) A new model for hydrogen-assisted cracking (hydrogen “embrittlement”). Metall Mater Trans B 3:441–455

Yue X (2013) Evaluation of heat-affected zone hydrogen-induced cracking in high-strength steels—dissertation. The Ohio State University, Columbus

Hollomon J, Jaffe L (1945) Time-temperature relations in tempering steel. Metal Technol 12:223–249

Martin ML, Fenske JA, Liu GS, Sofronis P, Robertson IM (2011) On the formation and nature of quasi-cleavage fracture surfaces in hydrogen embrittled steels. Acta Mater 59:1601–1606

Acknowledgements

The base metal and filler metal were provided by Cameron and ATS, respectively, and ATS conducted the cladding of Alloy 625 on AISI 8630 steel. Our thanks to Mr. Dean Hannam and Mr. Nash Ubale from Schlumberger (formerly Cameron International) who gave advice and guidance throughout the project, and to Mr. Tim Thompson from ATS who coordinated the production of weld overlays.

Funding

This project was supported by the Cameron International and Acute Technological Services (ATS) through membership in the NSF I/UCRC, Manufacturing & Materials Joining Innovation Center (MA2JIC).

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended for publication by Commission X - Structural Performances of Welded Joints - Fracture Avoidance

Rights and permissions

About this article

Cite this article

Dai, T., Lippold, J.C. The effect of postweld heat treatment on hydrogen-assisted cracking of 8630/Alloy 625 overlay. Weld World 62, 581–599 (2018). https://doi.org/10.1007/s40194-018-0578-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-018-0578-6