Abstract

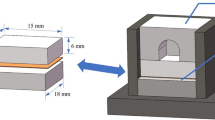

K465 superalloy was brazed with brazing clearance of 0.1 and 0.5 mm, respectively. The microstructures of the brazed joints were observed, and compositions of typical microzones were analyzed by means of scanning electron microscope (SEM), energy-dispersive spectroscopy (EDS), and electron probe microanalysis (EPMA). In addition, high-temperature tensile tests for the brazed joints were also conducted. The results showed that for the brazed joints with 0.1 mm clearance, the low-melting phases such as the white blocky shaped (W, Cr)B boride phases and gray skeletal phases M3B2 boride phases were mainly precipitated in the central region of the brazed seam. However, the microstructure of the brazed joints with 0.5 mm clearance, which was pre-filled fully with one type of Ni-based alloy powder prior to brazing, was remarkably improved. Compared to the brazed joints with 0.1 mm clearance, the pre-filling of the alloy powder changed the distribution and morphology of low-melting phases, which was favorable to the improvement in high-temperature tensile properties of the brazed joints with 0.5 mm clearance. At 900 °C, the average tensile strength of the brazed joints with 0.1 mm clearance was only 488 MPa, while the average tensile strength of the brazed joints with 0.5 mm clearance increased to 615 MPa, which is 75 % of the K465 base metal tensile strength.

Similar content being viewed by others

References

Wang D, Xiao C, Zhang G (2003) Effect of shell mould temperature on microstructure and mechanical properties of superalloy K465. J Iron Steel Res 15:208–211

Yu Q, Xiao C, Song J (2005) Melt treatment time on microstructure and mechanical properties of as-cast Ni-based superalloy K465. J Aeronaut Mater 5:1–4

Mao W, Zhou Y, Ye L (2008) Microstructures and properties of K465 superalloy joints brazed with different filler metals. Electric Weld Mach 38:65–68

Yang JX, Zheng Q, Sun XF, Guan HR, Hu ZQ (2006) Formation of μ phase during thermal exposure and its effect on the properties of K465 superalloy. Scr Mater 55:331–334

Radzievskii VN, Yu FG, Kachenko GGT (1999) High-temperature brazing of dissimilar materials with a wide brazing gap using a filler. Weld Int 13(3):245–248

Su CY, Chou CP, Chang WJ, Liu MH (2000) Effect of mechanical properties using different filler metals on wide-clearance activated-diffusion-brazed Ni-based superalloy. J Mater Eng Perform 9(6):663–667

Bakhtiari R, Ekrami A (2012) The effect of gap size on the microstructure and mechanical properties of the transient liquid phase bonded FSX-414 superalloy. Mater Des 40:130–137

Yang J, Zheng Q, Zheng X (2009) Transformation of MC type carbide in K465 alloy during heating/cooling cycles. Foundry 58:42–45

Liang H, Mao W, Sun J (2005) Microstructures of high temperature brazed joints of cast superalloy K465. J Mater Eng 7:7–11

H Zhuang, E. Lugscheider (1989) High temperature brazing (National Defense Industry Press) Chapter 3

Q Zhang, H Zhuang, (1989) Brazing and soldering manual (China Machine Press) Chapter 1

Pei Z, Li J, Zhao M, Tian Y (2008) Study on microstructures and properties of K465 alloy. J N Univ (Nat Sci) 29:1126–1129

Yang J, Zheng Q, Sun X, Guan H, Hu Z (2006) Relative stability of carbides and their effects on the properties of K465 superalloy. Mater Sci Eng A 429:341–347

Li X, Zhong Q, Cao C (2003) Wide-gap brazing between K403 and DZ4 superalloys. J Aeronaut Mater 23:11–15

E. Lugscheider, TH. Schittny, E. Halmoy (1989) “Metallurgical aspects of additive-aided wide-clearance brazing with nickel-based filler metals,” Welding Research Supplement 9–13

Huang X, Miglietti W (2012) “Wide gap braze repair of gas turbine blades and vanes—a review,”. J Eng Gas Turbines Power 134:010801-1–010801-17

McGuire D, Huang X, Nagy D (2010) “Effect of W addition on the nucleation of borides in the wide gap brazed joint,”. Gas Turbines Power 132(6):062101

Acknowledgments

This research work is sponsored by National Natural Science Foundation of China (Grant No.51410105004).

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended for publication by Commission XVII - Brazing, Soldering, and Diffusion Bonding

Rights and permissions

About this article

Cite this article

Liu, Y., Pan, H., Zhao, H. et al. The microstructures and mechanical properties of K465 superalloy joints, brazed with different clearances. Weld World 60, 93–98 (2016). https://doi.org/10.1007/s40194-015-0266-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-015-0266-8