Abstract

The demands for materials that integrate more than one functional imaging or therapeutic unit are of increasing interest for biomedical applications. Here, we present the step-by-step preparation of asymmetric and optically active particles, namely, Gd2O3@Ag, Gd2O3@Au, SiO2–N3@Au, and SiO2–SH@Au . Successful attachment of plasmonic nanoparticles to the surface of metal-oxide spheres without necessity of a potentially toxic inter-adhesive layer was proven by optical methods as well as X-ray photoelectron spectroscopy. The combination of optical and magnetic properties as present in Gd2O3@Ag and Gd2O3@Au Janus-type particles leads to dual-imaging probes for optical and magnetic resonance imaging. In addition, functional groups, such as azide groups, were linked to the surface of silica particles previous to Au nanoparticle attachment. Subsequent site-selective click reactions with 5-FAM were successfully performed as demonstrated by UV–Vis measurements. All described systems exhibited excellent long-term stability and can, therefore, be considered as promising candidates for theranostic applications.

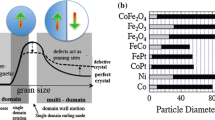

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The rapid evolution of nanoprobe applications in medicine demands advanced control over their intrinsic properties, which usually rely on the composition and shape of nanoprobes, as well as their proper functional surface modification [1]. Beside conventional preparation methods, such as solvothermal reactions, a variety of specialized protocols for nanocluster formation, e.g., using nanoreactors [2] are reported in the literature. In the field of biomedicine, nanoparticles (NPs) have become more and more important. Besides drug delivery applications, NPs are widely used for in vivo imaging techniques. To date, a variety of nanocolloidal systems are reported for optical bioimaging applications including rare-earth-doped nanoparticles [3], carbon nanodots [4], and metallic nanoshells [5]. While optical methods are range limited by light absorption of the examined body, and still, in need of invasive techniques, magnetic resonance imaging (MRI) is suitable for non-invasive imaging of malignant tissues. Being well-established as a strong T1 contrast agent [6, 7], Gd2O3 NPs bare a large magnetic moment of 7.94 μB per Gd3+ ion, leading to a high longitudinal relaxivity of nearby water protons.

In general, molecular surface modifications of these particles can be performed by grafting methods [8], whereas biomedically useful surface modifications are mostly achieved via cycloaddition reactions, e.g., the famous click reaction [9,10,11], biotin–streptavidin interactions [12], and carbodiimide coupling reactions [13]. By these techniques, immobilization of antibodies, drugs, and vitamin units is achieved and widely reported in the literature [14,15,16]. Among a broad variety of surface grafting techniques, click reactions have emerged as one of the most commonly used functionalization strategies based on their high selectivity, the tolerance of a wide range of solvents and pH and their high yield even at room temperature [11]. The most prominent type of click reaction is the copper(I) catalyzed alkyne–azide click reaction which leads to the formation of a stable triazole ring. While the non-catalyzed Huisgen reaction produces an unspecific mixture of 1,4 and 1,5-disubstitution products, only 1,4 disubstituted 1,2,3-triazoles are formed when copper is employed as catalyst. Besides alkyne–azide coupling reactants, thiol-ene and thiol-yne click reactions offer additional copper-free pathways for surface chemistry. As an example, Zhang et al. reported a successful immobilization of boronic acid on magnetic NPs for side-selective capture of glycoproteins [17]. In fact, it has been shown that click reactions offer larger efficiencies than their prominent carbodiimide counterparts [15]. However, all these techniques lack a chemical side selectivity, which results in an unspecific localization of ligands on the particle surface. The attachment of two types of ligands to one particle thus still remains a major challenge. In this regard, Janus-type particles, which possess an asymmetric geometry, have found increasing attention during the last years. The combination of two material types in one particle offers beneficial physicochemical properties that can help to overcome limitations of one material. For example, an asymmetric combination of plasmonic and magnetic characteristics in one particle provides a novel platform for multimodal imaging and therapeutic applications. Simply spoken, only one injection would be needed for detection of cancer by MRI and a direct treatment of infected cells by photothermal therapy [18]. Janus-type particles have been applied as sensors [19, 20], catalysts [21], emulsifiers [22, 23], and building blocks for the formation of self-assembled superstructures [24], reports on an asymmetric combination of plasmonic and magnetic properties for biomedical applications are rather rare [25]. In addition, a variety of preparation methods are presented for polymeric Janus particles, as reviewed extensively [25, 26], while a controllable preparation of biocompatible ceramic NPs, baring asymmetric functionalities is still missing. Even though a simple sputtering approach of gold NPs on immobilized silica particles was already presented in 1988 by Casagrande et al. [27]., shell stability could only be achieved by adhesive layers, such as Ti/W alloy or Ni, at the metal-oxide interface [28, 29]. However, due to the cytotoxic properties of these metals, these interlayers lower the biomedical applicability of the particles dramatically and limit their possible application for in vivo studies. In this approach, we present a simple method for the preparation of metal-oxide particles which can be surface decorated with plasmonic silver or gold nanoparticles. Unlike the procedures reported in the literature, no metallic inter-adhesive layers are needed for the formation of long-term stable dispersions of Janus-type functionalized ceramic particles. Instead, oxidative surface activation techniques, such as ozone treatment were used for an increased shell stability.

Shape-controlled particles were designed to have two non-centrosymmetric oriented functionalities. Plasmonic properties were added to previously prepared phase pure Gd2O3 and functionalized silica particles by Ag and Au NPs deposition without any metallic interlayers. Using a “step-by-step” approach, consisting of particle immobilization, magnetron sputtering and dispersing, each part of the synthesis can be separately controlled depending on the desired application. Therefore, the presented technique offers a large flexibility in variation of the core, shell, and functionalization. The suitability of as-prepared Janus-type particles for potential biomedical applications was demonstrated by attaching a dye as model molecule selectively to the silica-side via click reaction. To the best of our knowledge, we are the first to present a long-term stable Janus-type particle system without any additional interlayers in between the oxide and noble metal, prepared by a simple sputtering technique. A schematic drawing of the preparation process is given in Fig. 1.

Experimental part

Materials

FTO glass substrates (7 Ω/sq) were received from Pilkington, 3″ × 5 glass substrates were received from VWR and cut into 1 × 1 cm pieces. Gold and silver sputter targets (99.999% purity) were bought from Quorum Technologies Ltd and sputtered using a Quorum TS 150. 5-Carboxyfluorescein–alkyne (5-FAM) was purchased from Lumiprobe GmbH. All other chemicals used in this work were purchased from Sigma-Aldrich and used as received.

Synthesis of spherical Gd2O3 particles

The gadolinium oxide particles were prepared following the homogeneous precipitation method using urea [30]. A Gd(NO3)3 solution (1 mL, 1 M) was placed in a 100 ml round bottom flask and was further diluted with 50 mL of water. Urea (2 g) was added to the flask and the mixture was stirred for 2 h at room temperature to form a homogeneous solution. Afterwards, reaction temperature was increased to 90 °C for 2 h to form a white milky dense solution. The particles were separated using a centrifuge at 11,000 rpm for 20 min, and washed three times with water, water–ethanol and ethanol. Finally, the particles were dried in an oven at 60 °C overnight. The particles were further annealed at 800 °C for 150 min (600 °C/h) to obtain Gd2O3 particles.

Synthesis of silica spheres (SiO2)

Silica particles were prepared using the Stöber method [31]. In detail, ethanol (90.00 mL), deionized water (32.50 mL), and NH4OH solution (2.25 mL, 28%) were mixed together at 25 °C. Tetraethyl orthosilicate (TEOS, 7.75 mL, 35 mmol) was added under vigorous stirring and the dispersion was stirred for 2.5 h. Afterwards, the particles were collected by centrifugation (11,000 rpm, 15 min). The precipitated particles were redispersed in ethanol and water (1:1), followed by collection of the particles by centrifugation. This procedure was repeated once. Finally, the particles were dispersed in deionized water (15 mL).

Formation of azide functionalized silica spheres (SiO2–N3)

Azide functionalized silica spheres were prepared by surface treatment of the particles with 11-bromoundecyltrichlorosilane [16]. The previously prepared SiO2 (200 mg, 3.33 mmol) sub-micrometer spheres were dispersed in a mixture of toluene (anhydrous, 50 mL) and dimethyl formamide (DMF, anhydrous, 5 mL), which was added to increase the dispersibility of the particles. Afterwards, the dispersion was heated up to 60 °C and 11-bromoundecyltrichlorosilane (422 µL, 1.44 mmol) was added rapidly. The reaction proceeded at 60 °C for additional 19 h. Particles were separated by centrifugation and washed at least four times with toluene. The final particles were dried for 12 h at ambient conditions. Afterwards, the bromine functionalized particles were dispersed in DMF (5 mL) and NaN3 (200 mg, 3.07 mmol) was added. The reaction was stirred for 40 h at 25 °C. Collection of the particles was performed with a centrifuge (4400 rpm, 15 min), followed by five washing steps. Finally, the particles were dried for 12 h at 25 °C.

Formation of thiolated silica spheres (SiO2–SH)

Thiol functionalized silica spheres were prepared according to Claesson et al. [32]. In this procedure, 3-mercaptopropyl trimethoxysilane (MPTMS, 1.5 mL, 7.16 mmol) was added to an aqueous dispersion (70 mg/mL) of silica spheres. The reaction proceeded for 45 min at ambient conditions. Afterwards, the solution was heated to 80 °C for 60 min. The particles were collected via centrifugation (9 000 rpm, 10 min) and washed three times with ethanol. Finally, the particles were dispersed in ethanol (40 mL).

Substrate preparation

FTO and glass substrates were washed for 15 min each with acetone, deionized water with 2% Helmanex III soap, and isopropyl alcohol in an ultrasonic bath kept at 50 °C. Before spin coating, the FTOs were treated with oxygen plasma for 15 min and the glass substrates were treated oxidatively in an UV–ozone cleaner (Dinier©, ELG 100 s) to remove any remaining organic impurities and to increase the surface wettability. All substrates were used directly after activation.

Preparation of Janus-type Gd2O3@Ag and Gd2O3@Au particles

The prepared Gd2O3 particles (50 mg) were placed in an argon flushed vial equipped with a stirring bar and transferred to a nitrogen filled glovebox. Isopropanol (anhydrous, 600 µL) was added to form a homogeneous white dispersion stirred for 2 h. FTO substrates were also transferred to the glovebox and each was coated with Gd2O3–isopropanol solution (50 µL). Spin coating of substrates was performed with an acceleration rate of 800 rpm/s for 45 s at 1000 and 3000 rpm, respectively. The coated substrates were placed on a hot-plate at 100 °C to dry and ensure removal of solvent. Coated substrates were placed inside a sputtering machine. Silver and gold were sputtered onto the particles layer at a discharge current of 20 mA at 20 mbar for 20 and 40 s, respectively.

Preparation of Janus-type SiO2–N3@Au and SiO2–SH@Au particles

SiO2–N3 or SiO2–SH dispersion (10 µL, 70 mg mL−1) was transferred onto an activated glass slide. The dispersion was allowed to cover the substrate completely and dried using a spin-coating technique. The dried sample was placed in the UV chamber for further 30 min and gold was sputtered onto the substrates (20 mA, 30 s). Finally, the particles were collected in ethanol (4 mL) by sonification.

Covalent attachment of 5-FAM to SiO2–N3@Au particles

CuSO4 (12.5 mg, 0.07 mmol), l-histidine (19.5 mg, 0.13 mmol), and sodium ascorbate (49 mg, 0.25 mmol) were each dissolved in water (250 µL). Afterwards, CuSO4, a 5-FAM-alkyne solution (100 µL, 5 mM), histidine and sodium ascorbate were mixed subsequently under stirring in a 10 mL reaction vessel. Finally, the aqueous dispersion of SiO2–N3@Au particles (1 mL, ~ 7 mg mL−1) was added and the reaction was allowed to proceed for 4 h. The final particles were collected via centrifugation (1600 rpm, 15 min) and washed five times. Finally, the particles were dried for 14 h under ambient conditions.

Characterization

All measurements were performed under ambient conditions and in neutral pH. X-ray diffraction (XRD) analysis of Gd2O3 particles was carried out on an STOE-STADI MP diffractometer equipped with a Cu (R = 0.15406 nm) source and operating in transmission mode. A scan rate of 0.05°/s was applied to record the pattern in the 2θ range of 10°–80°. Scanning electron micrographs were performed on an FEI Nova Nano SEM 430. Energy-dispersive X-ray spectroscopy was performed on an Apollo X EDAX. (Working distance 5 mm; entry angle 35°). X-ray photoelectron spectroscopy (XPS) was performed on an ESCA M-Probe (Surface Science Instruments) using Al-Kα-radiation (1486.6 eV). TEM measurements were carried out using a ZEISS LEO 902 microscope operating at 120 kV with LaB6 cathode in a bright field mode. The samples were deposited onto a carbon coated copper grid. The mean diameter was statistically determined from a varying number of particles from bright field micrographs. Dynamic light scattering (DLS) and ζ-potential measurements were performed with a Malvern Instruments Zetasizer Nano ZS (operating wavelength: 633 nm). All values and standard deviations presented here were calculated out of five measurements. Measurements were performed in polystyrene cuvettes. FT-IR spectra were collected using a Perkin Elmer Spectrum 400. Powder-like samples were measured in the range of 4000–400 cm−1. For Raman spectroscopy, a Horiba Jobin–Yvon spectrometer in triple subtractive mode equipped with a liquid nitrogen-cooled CCD detector, 1800 gr/mm gratings, and a laser wavelength of 532 nm was used. The incident beam angle was 45° concerning the a–b plane of the sample. Before the measurement, the powder-like sample was placed between two previously cleaned microscopic glass slides.

Results and discussion

Particle preparation and functionalization

The hydrogen-carbonate precursor Gd(OH)CO3∙H2O was prepared following the urea-based homogeneous precipitation method, established by Matijevic and coworkers in 1988 [30]. While refluxing an aqueous solution of Gd3+ salt, urea serves as a precipitating agent for the Gd3+ ions by shifting the pH value into basic conditions due to self-decomposition at elevated temperature. The Gd(OH)CO3∙H2O precursor was further subjected to thermal treatment at 850 °C for 2 h. XRD analysis (Fig. 2a) revealed a highly crystalline Gd2O3 phase, indicating a successful conversion of the Gd(OH)CO3∙H2O precursor. Diffration peaks were observed at 20.32°, 28.86°, 33.39°, 47.92°, 56.75°, 61.94°, as well as at 71.07° and indexed to the (211), (222), (440), (444), (622), (640), and (811) planes in cubic space group Ia-3 (No. 206), respectively. No crystalline secondary phases or impurities could be detected within the detection limit.

The electron microscope images in Fig. 2b illustrate the size and morphology of the Gd(OH)CO3∙H2O particles before thermal treatment. As synthesized particles were spherical in shape, nearly, monodisperse and homogeneously distributed with average size of 100–120 nm, fitting the demand of biological application. Furthermore, the particles’ uniform surface is preferred for targeting ligands’ conjugation and imaging probes [33]. It is noteworthy that the particles did not show any changes in size or morphology after calcination, as clearly presented in Fig. 2c. Even for a rapid heating rate of 10 °C/min, the particles maintained their regular morphology in contrast to the previous work of Di et al., reporting an optimal heating rate of 2 °C/min to prevent shrinkage of the particles and maintaining their original morphology [34].

Silica particles with an average hydrodynamic diameter of 170.6 (7) nm, as proven by DLS measurements, were prepared according to the Stöber method [31]. FT-IR measurements (see Fig. 3a) revealed characteristic silica bands at 1052 cm−1 (Si–O–Si sym. stretching), 1200 cm−1 (Si–O–Si asym. stretching), 935 cm−1 (Si–O, non-bridging), 784 cm−1 (Si–O–Si, bending), and 445 cm−1 (O–Si–O, bending) [35]. Free hydroxyl functions were detected at 3350 cm−1, while physically adsorbed water and ethanol molecules were measured at 1632 and 1458 cm−1, respectively. The particles stability in dispersion was analyzed as ζ-potential and resulted in an excellent value of − 49.3 (4) mV, indicating the formation of a long-term stable dispersion [36]. After surface treatment, a successful formation of SiO2–N3 spheres was clarified using FT-IR spectroscopy.

a FT-IR spectrum of prepared silica spheres (grey) and azide functionalized silica spheres (red, azide band is marked in green), and b Raman spectrum of thiolated silica spheres (characteristic thiol bands are marked in red), c TEM micrographs of SiO2–N3@Au particles, and d TEM micrographs of SiO2–SH@Au particles. All characteristic absorption bands for azide and thiol functionalization were detected in IR and Raman spectra, respectively. Furthermore, a clear asymmetric location of gold NPs on the particles is demonstrated in TEM images

As presented in Fig. 3a, a clear signal was visible at 2102 cm−1, related to the successful attachment of the azide onto the particles surface [16, 35]. DLS analysis proves the formation of particles with an average hydrodynamic diameter of 229 (4) nm and an average ζ-potential of – 19 (2) mV, where the replacement of negatively charged hydroxyl functions by azide groups resulted in the observed shift towards positive values of the ζ-potential.

For obtaining thiol functionalized silica particles, potentially usable for thiol-ene coupling, previously prepared silica particles were surface functionalized with MPTMS [32]. Raman spectroscopy proved a successful attachment of the thiol function on the particles surface (Fig. 3b). The bands related to the thiol group are measured at 2571 cm−1 (marked in red, S–H bond stretching), 1261 cm−1 (wag vibration of the S–CH2 group), and 650 cm−1 (C–S bond stretching) [37], while C–H bands were observed at 2928 cm−1 (antisymmetric C–H stretching of the CH2 groups) and 2894 cm−1 (symmetric C–H stretching of the CH2 groups), as well as at 1431 cm−1 (CH2 deformation). This indicates that non-oxidized thiol groups are present on the surface. Therefore, an immobilization of target molecules via thiol-ene reactions should be possible. The average hydrodynamic diameter of SiO2–SH particles was measured as 267 (3) nm by DLS analysis, whereas the obtained ζ-potential was – 45 (1) mV. As in case of silica particles, this negative value indicates a long-term dispersability and a negative surface charge consisting of deprotonated thiol groups.

Janus particle formation

For controllable asymmetric functionalization, previously described particles were immobilized on carrier substrates using spin-coating technique. The substrates were treated either with oxygen plasma or UV–ozone prior to particle deposition, providing a good solvent wettability and easy removal of organic residues from the substrate surface. The coated substrates were dried subsequently to remove any remaining solvent. A thin layer (< 10 nm) of silver and gold was deposited onto the surface of the NPs via magnetron sputtering at various discharge currents and times, depending on the material. The resulting coated particles were then released from the supporting substrate and redispersed in an aqueous solution by immersing the substrate under sonication for a few seconds.

The XRD patterns for Gd2O3@Ag and Gd2O3@Au particles are presented in Fig. 4a, c, respectively. Diffraction peaks with the highest intensity for metallic silver and gold were observed at 38.04° (Ag) and 38.10° (Au), corresponding to the (111) plane of cubic (fcc) lattice and in excellent agreement with the standard powder diffraction cards of gold and silver (see Fig. 4a, c). The dispersions of hetero-structured particles presented monodisperse size distribution, as confirmed by SEM, maintaining their original spherical shape after asymmetric functionalization, as clearly visible for Gd2O3@Ag and Gd2O3@Au particles in Fig. 4b, d, respectively. The noble metal layer was localized asymmetrically on one side of the spheres, whereas the backside of Gd2O3 particles, protected by the substrate, remained non-functionalized. While cluster formation of Ag and higher surface roughnesses, providing oxide formation, are demonstrated for Gd2O3@Ag, Au functionalization resulted in a smoother film formation, as visible in Fig. 4d. Furthermore, no Au particles are visible on the Gd2O3 particles surface in contrast to the Gd2O3@Ag particles. As for Gd2O3 Janus particles, no unattached gold NPs were observed for SiO2–N3@Au and SiO2–SH@Au. However, isolated Au NPs were measured at the surface, having an average particle diameter of 8 ± 2 nm, as determined by TEM micrographs (Fig. 3c, d).

a XRD profile for spin-coated Gd2O3 particles on the surface of the FTO substrate after sputtering of Ag (JCPDS C87-0720), b colorized SEM images for acorn-like Gd2O3@Ag particles, c after sputtering of Au (JCPDS C04-0784), and d colorized SEM images for Gd2O3@Au particles. A clear asymmetric decoration of metallic Ag and Au on the Gd2O3 is clarified by XRD, whereas SEM images revealed a rougher shell in case of Ag NP immobilization. In contrast, decoration of carrier particles resulted in smoother shell formation

In fact, all samples showed long-term stability even after removal from the substrate surface, as confirmed by SEM measured for the same particle dispersions after weeks (Figure S2). It can be clearly seen that the sputtered metallic clusters adhere strongly to the Gd2O3 surface and the dispersion of particles using ultrasonic bath did not deform the spheres or detached metallic NPs. Moreover, it has been reported that the deposition of noble metals on metal-oxide surfaces needs an adhesion layer such as Ti/W alloy or Ni, to obtain an intimate and long lasting contact of the film [28, 29]. However, it should be noted that asymmetrical capping of the presented particles with Ag and Au was achieved without any additional interlayer support.

In case of Gd2O3-based Janus-type particles, a red shift of surface plasmon resonance of the silver and gold due to direct contact with the oxide was observed. The UV–Vis absorption spectrum of Gd2O3@Ag Janus-type particles in Fig. 5a shows two absorption bands with maxima located at 388 and 529 nm, while gold plasmon bands appeared at 567 and 525 nm for Gd2O3@Au particles (Fig. 5b) and SiO2–N3@Au Janus particles (Fig. 5c), respectively. In case of SiO2–N3@Au, the obtained result is in agreement with reports on immobilized Au NPs with comparable diameter. While unattached Au NPs are reported to have an absorption band at 519 nm [38], a red shift of absorption bands was reported for immobilized Au NPs on dielectric surfaces [39]. In addition, for Gd2O3@Ag Janus particles (see Fig. 5a), isolated Ag NPs at the Gd2O3 particle surface could be measured at 388 nm. As for SiO2–N3@Au particles, a red shift of the absorption signal can be dedicated to an immobilization of plasmonic NPs at a dielectric interface. The second absorption at 529 nm can be attributed to the Ag shell. While equally sized Ag NPs should have an absorption band around 370 nm, according to Mie theory [38], red shift caused by immobilization at dielectric interfaces does not explain the observed red shifts. Moreover, an increase in shell roughness is known to cause comparable red shifts [40]. As previously discussed, the obtained Ag shell has a significantly larger roughness in contrast to the Au shell. Consequently, a bigger red shift (red shift: 159 nm) was measured in contrast to the smoother Au shell (red shift: 48 nm). Therefore, UV–Vis measurements are in good agreement with already presented TEM images and additionally emphasize the Janus particles stability in dispersion. For SiO2–SH@Au particles, no plasmonic absorption was detected. Most likely, strong particle interactions caused the formation of agglomerates, leading to increased light scattering at these superstructures, hindering the absorption band of attached gold NPs.

UV–Vis measurements of a Gd2O3@Ag particles, b Gd2O3@Au particles, and c SiO2–N3@Au particles. In case of Gd2O3@Ag particles, two absorption bands were measured corresponding to NP and shell formation on dielectric surfaces, whereas for Gd2O3@Au particles, one absorption related to the noble metal shell is measured. For SiO2–N3@Au particles, plasmonic absorption reliable to Au NP immobilization at dielectric surfaces is detected

XPS analysis of Janus-type Gd2O3 particles

The composition and interaction between noble metals and ceramic host particles (Gd2O3) were studied in detail by XPS, whereby high-resolution spectra were collected for detailed investigations of the interface between plasmonic surface and oxidic host particle. Charge correction was carried out in all spectra considering the charge shift of the C 1 s peak of adventitious carbon. An XPS survey spectrum of bare Gd2O3 NPs is presented in Figure S3, demonstrating a peak at 136.3 eV which is related to the binding energy of Gd 4d, whereas the presence of adventitious carbon from atmospheric exposure after spin-coating procedure is confirmed by the C 1 s peak at 284.81 eV. The O 1 s surface peak at 530.31 eV is dedicated to Gd2O3 and in good agreement with reported data of O 1 s in Gd2O3 at 530.6 eV [41].

However, an increased atomic concentration of oxygen is explainable by the previously described attachment of CO2 after spin coating as well as oxygen from FTO carrier substrate. An Sn 3d peak is observed in all spectra due to the use of FTO as substrate. Figure 6a presents the XPS survey spectrum of Gd2O3@Ag sample, demonstrating a noticeable decrease in signal intensity of the Gd, O, C, and Sn peaks due to the complete coverage of host matrix by Ag. The high-resolution spectrum of the Ag 3d region (Fig. 6b) showed two main peaks for Ag 3d 5/2 and Ag 3d 3/2 at 368.2 and 374.2 eV, respectively. Both Ag 3d signals are located between Ag metal (368.3 and 374 eV for Ag 5/2 and Ag 3/2, respectively) and AgO (367.8 eV for Ag 3d 5/2 and 373.6 eV for Ag 3/2) [42, 43]. The 3d 5/2 and 3d 3/2 doublets for Ag in the fitting spectra have almost 3:2 peak area ratios, in agreement with the specific area ratios based on the degeneracy of d spin state. Weaver et al. reported Ag 3d peak shifts towards lower binding energy values upon oxidation [44]. Accordingly, our results (the position of Ag 3d signal as well as the splitting of spin orbit component of almost 6.0 eV) are consistent with silver compounds and metallic silver which provide unambiguous information on the identity of the Ag oxidation state. Nevertheless, the Ag 3d peaks have a full-width at half-maximum (FWHM) of 1.4 eV which lies in between those reported for silver metal (1.12 eV) and silver oxide (1.8 eV) [42]. Moreover, plasmonic signals of metallic silver at 372 and 378 eV for 3d 3/2 and 3d 5/2 are not resolved, most likely caused by a decrease in Ag amount due to oxidation, as clearly demonstrated in the XPS spectra, as presented in Fig. 6b. Indicated by peak position and FWHM, a mixture of AgO and Ag metal is apparently located on the surface of the particles. It is known that silver is a very reactive noble element and can form silver oxide under ambient conditions. For example, reports on the existence of a few monolayers of AgO on silver exist [45]. As mentioned in the experimental section, sputtering of Ag on the Gd2O3 surface was performed under vacuum and Ar atmosphere, the oxidation of Ag is considered to occur in aerated conditions during the handling of the sample before measurement. For detailed statistics, Ag Auger parameters need to be calculated. Unfortunately, the peak position of Ag M4N45N45 Auger peak is around 1130 eV [46] which is outside the range of the detector used in this study (Range: 0–1000 eV). Figure 6c and d present the XPS survey and high-resolution spectra of Au 4f in Gd2O3@Au system, respectively. The new intense peak at 335.3 eV results from the Au layer sputtered on the surface of particles, while the original peaks of Gd2O3 became less intense. In Fig. 6d, the Au 4f curve fitting of the Au/Gd2O3 sample displayed two Au 4f components at 84.35 and 88.02 eV, which correspond to Au 4f 5/2 and Au 4f 7/2 spin–orbit component, respectively. [47, 48] The difference in binding energy of 3.7 eV between the Au 4f 7/2 and Au 4f 5/2 peaks and the FWHM of fitted peaks (< 0.9 eV) further emphasize the presence of Au metal on the particles surface. The calculated peak ratio of 3d 7/2: 3d 5/2 for Au in the fitting spectra is close to 4:3, the area ratio of f subshell. In contrast to Gd2O3@Ag particles, no peak corresponding to gold oxide was detected. Since Au is less prone to oxidation then Ag, it was long considered a completely inert metal, and the oxidation of Au by O2 without additional heating is not favored [49].

a XPS survey spectrum of Gd2O3@Ag and b High-resolution Ag 3d spectra of the Gd2O3@Ag particles (line shape of fitting: AgO GL(20), Ag GL(20) T(S.S). c XPS survey spectrum of Gd2O3@Au and d High-resolution Au 4f spectra of the Gd2O3@Au particles [line shape of fitting: GL (82) T (S.S)]. While an oxide formation is detected in case of Gd2O3@Ag particles, no oxide is measured for Gd2O3@Au particles

Further functionalization of silica Janus-type particles

As already reported by our group [16], click chemistry has a high potential for the bioconjugation of NPs. To investigate the applicability of SiO2–N3@Au particles presented here, a model molecule (5-Carboxyfluorescein, 5-FAM) was selectively attached to the azide functionalized side of the particles via a copper catalyzed click reaction [50].

Spectroscopical methods (UV–Vis, FT-IR) prove the successful attachment of the dye, as presented in Fig. 7. The disappearance of the characteristic azide band at 2100 cm−1 in the FT-IR spectrum (Fig. 7b) after the click reaction (violet) clarifies a successful surface modification. In addition, at 1435 and 1450 cm−1, 1,2,3-triazole bands [16] could be observed. Furthermore, absorption bands related to the triazole [51] and 5-FAM [52] were measured in the UV–Vis spectrum (Fig. 7a) at 230 and 425 nm, respectively, whereas no plasmonic signal was detected. Most likely, the surface plasmon resonance is hindered by the attached dye.

Conclusion

Plasmonic silver and gold NPs were successfully immobilized on phase pure Gd2O3 and functionalized silica spheres, leading to the formation of non-centrosymmetric dispersable systems. In contrast to literature reports, no adhesive interlayer was needed to guarantee an intimate contact at the NP–metal interface, still present after weeks, as proven by SEM and TEM. UV–Vis spectroscopy revealed a plasmonic activity for Gd2O3@Ag, Gd2O3@Au, and SiO2–N3@Au. In case of Gd2O3@Ag and Gd2O3@Au, the red shift of the absorption bands was explained by shell effects, such as variations in roughness and the presence of nanoclusters. In addition, XPS analysis proved the metallic character of the silver and gold NPs, only a few oxidized AgO species were observed, which could be attributed to the exposure of the sputtered sample to aerated conditions. Further functionalization of SiO2–N3@Au with a model molecule (5-FAM) via click chemistry was successfully performed and proven by UV–Vis and FT-IR spectroscopy. Our results demonstrate that this synthesis route avoids the use of expensive reagents and solvents and is capable of generating functional layers on sub-micrometer sized particles without additional adjustments. Furthermore, we prove the applicability of the presented approach to a variety of crystalline and amorphous systems, providing new possibilities in material and interface engineering.

References

Perro, A., Reculusa, S., Ravaine, S., Bourgeat-Lami, E., Duguet, E.: Design and synthesis of janus micro-and nanoparticles. J. Mater. Chem. 15, 3745–3760 (2005)

Chen, Y., Yang, D., Yoon, Y.J., Pang, X., Wang, Z., Jung, J., He, Y., Harn, Y.W., He, M., Zhang, S.: Hairy uniform permanently ligated hollow nanoparticles with precise dimension control and tunable optical properties. J. Am. Chem. Soc. 139, 12956–12967 (2017)

Hemmer, E., Acosta-Mora, P., Méndez-Ramos, J., Fischer, S.: Optical nanoprobes for biomedical applications: shining a light on upconverting and near-infrared emitting nanoparticles for imaging, thermal sensing, and photodynamic therapy. J. Mater. Chem. B 5, 4365–4392 (2017)

Zhu, S., Meng, Q., Wang, L., Zhang, J., Song, Y., Jin, H., Zhang, K., Sun, H., Wang, H., Yang, B.: Highly photoluminescent carbon dots for multicolor patterning, sensors, and bioimaging. Angew. Chem. 125, 4045–4049 (2013)

Halas, N.: Playing with plasmons: tuning the optical resonant properties of metallic nanoshells. MRS Bull. 30, 362–367 (2005)

Xu, W., Miao, X., Oh, I.T., Chae, K.S., Cha, H., Chang, Y., Lee, G.H.: Dextran-coated ultrasmall Gd2O3 nanoparticles as potential T1 MRI contrast agent. ChemistrySelect 1, 6086–6091 (2016)

Huang, H., Weng, L., Golzarian, J.: Optimizing contrast effect in T1-weighted magnetic resonance imaging of Gd2O3-based nano-agent via dopamine chelation. Neurosci. Biomed. Eng. 4, 249–254 (2016)

Chen, Y., Gan, T., Ma, C., Wang, L., Zhang, G.: Crystallization of polymer chains chemically attached on a surface: lamellar orientation from flat-on to edge-on. J. Phys. Chem. B 120, 4715–4722 (2016)

Liang, L., Astruc, D.: The copper (I)-catalyzed alkyne-azide cycloaddition (CuAAC)“click” reaction and its applications. An overview. Coord. Chem. Rev. 255, 2933–2945 (2011)

Presolski, S.I., Hong, V.P., Finn, M.: Copper-catalyzed azide-alkyne click chemistry for bioconjugation. Curr. Protoc. Chem. Biol. 3, 153–162 (2011)

Kolb, H.C., Finn, M., Sharpless, K.B.: Click chemistry: diverse chemical function from a few good reactions. Angew. Chem. Int. Ed. 40, 2004–2021 (2001)

Song, E.-Q., Hu, J., Wen, C.-Y., Tian, Z.-Q., Yu, X., Zhang, Z.-L., Shi, Y.-B., Pang, D.-W.: Fluorescent-magnetic-biotargeting multifunctional nanobioprobes for detecting and isolating multiple types of tumor cells. ACS Nano 5, 761–770 (2011)

Kuhn, S.J., Finch, S.K., Hallahan, D.E., Giorgio, T.D.: Proteolytic surface functionalization enhances in vitro magnetic nanoparticle mobility through extracellular matrix. Nano Lett. 6, 306–312 (2006)

Sudimack, J., Lee, R.J.: Targeted drug delivery via the folate receptor. Adv. Drug Deliv. Rev. 41, 147–162 (2000)

Bolley, J., Guenin, E., Lievre, N., Lecouvey, M., Soussan, M., Lalatonne, Y., Motte, L.: Carbodiimide versus click chemistry for nanoparticle surface functionalization: a comparative study for the elaboration of multimodal superparamagnetic nanoparticles targeting αvβ3 integrins. Langmuir 29, 14639–14647 (2013)

Ilyas, S., Ilyas, M., van der Hoorn, R.A., Mathur, S.: Selective conjugation of proteins by mining active proteomes through click-functionalized magnetic nanoparticles. ACS Nano 7, 9655–9663 (2013)

Koo, H., Lee, S., Na, J.H., Kim, S.H., Hahn, S.K., Choi, K., Kwon, I.C., Jeong, S.Y., Kim, K.: Bioorthogonal copper-free click chemistry in vivo for tumor-targeted delivery of nanoparticles. Angew. Chem. Int. Ed. 51, 11836–11840 (2012)

Lal, S., Clare, S.E., Halas, N.J.: Nanoshell-enabled photothermal cancer therapy: impending clinical impact. Acc. Chem. Res. 41, 1842–1851 (2008)

Hu, S.-H., Gao, X.: Nanocomposites with spatially separated functionalities for combined imaging and magnetolytic therapy. J. Amer. Chem. Soc. 132, 7234–7237 (2010)

Xu, C., Xie, J., Ho, D., Wang, C., Kohler, N., Walsh, E.G., Morgan, J.R., Chin, Y.E., Sun, S.: Au–Fe3O4 dumbbell nanoparticles as dual-functional probes. Angew. Chem. 120, 179–182 (2008)

Ebbens, S.J., Howse, J.R.: Direct observation of the direction of motion for spherical catalytic swimmers. Langmuir 27, 12293–12296 (2011)

Kumar, A., Park, B.J., Tu, F., Lee, D.: Amphiphilic janus particles at fluid interfaces. Soft Matter 9, 6604–6617 (2013)

Chen, Q., Whitmer, J.K., Jiang, S., Bae, S.C., Luijten, E., Granick, S.: Supracolloidal reaction kinetics of janus spheres. Science 331, 199–202 (2011)

Walther, A., Drechsler, M., Rosenfeldt, S., Harnau, L., Ballauff, M., Abetz, V., Müller, A.H.: Self-assembly of janus cylinders into hierarchical superstructures. J. Amer. Chem. Soc. 131, 4720–4728 (2009)

Kaewsaneha, C., Tangboriboonrat, P., Polpanich, D., Eissa, M., Elaissari, A.: Janus colloidal particles: preparation, properties, and biomedical applications. ACS Appl. Mater. Interfaces. 5, 1857–1869 (2013)

Walther, A., Müller, A.H.: Janus particles: synthesis, self-assembly, physical properties, and applications. Chem. Rev. 113, 5194–5261 (2013)

Casagrande, C., Veyssie, M.: «Grains janus » : réalisation et premières observations des propriétés interfaciales. C. R. Acad. Sci. (Paris) 306, 1423–1425 (1988)

Lu, Y., Xiong, H., Jiang, X., Xia, Y., Prentiss, M., Whitesides, G.M.: Asymmetric dimers can be formed by dewetting half-shells of gold deposited on the surfaces of spherical oxide colloids. J. Amer. Chem. Soc. 125, 12724–12725 (2003)

Love, J.C., Gates, B.D., Wolfe, D.B., Paul, K.E., Whitesides, G.M.: Fabrication and wetting properties of metallic half-shells with submicron diameters. Nano Lett. 2, 891–894 (2002)

Hsu, W.P., Ronnquist, L., Matijevic, E.: Preparation and properties of monodispersed colloidal particles of lanthanide compounds. 2. cerium (IV). Langmuir 4, 31–37 (1988)

Stöber, W., Fink, A., Bohn, E.: Controlled Growth of monodisperse silica spheres in the micron size range. J. Colloid Interface Sci. 26, 62–69 (1968)

Claesson, E., Philipse, A.: Monodisperse magnetizable composite silica spheres with tunable dipolar interactions. Langmuir 21, 9412–9419 (2005)

Cho, H.-S., Dong, Z., Pauletti, G.M., Zhang, J., Xu, H., Gu, H., Wang, L., Ewing, R.C., Huth, C., Wang, F.: Fluorescent, superparamagnetic nanospheres for drug storage, targeting, and imaging: a multifunctional nanocarrier system for cancer diagnosis and treatment. ACS Nano 4, 5398–5404 (2010)

Di, W., Ren, X., Zhao, H., Shirahata, N., Sakka, Y., Qin, W.: Single-phased luminescent mesoporous nanoparticles for simultaneous cell imaging and anticancer drug delivery. Biomaterials 32, 7226–7233 (2011)

Hesse, M., Meier, H., Zeeh, B.: Spektroskopische methoden in der organischen chemie. Georg Thieme Verlag, Stuttgart (2005)

Hunter, R.J.: Zeta potential in colloid science: principles and applications. Academic press, London (2013)

Vivero-Escoto, J.L., Huxford-Phillips, R.C., Lin, W.: Silica-based nanoprobes for biomedical imaging and theranostic applications. Chem. Soc. Rev. 41, 2673–2685 (2012)

Myroshnychenko, V., Rodríguez-Fernández, J., Pastoriza-Santos, I., Funston, A.M., Novo, C., Mulvaney, P., Liz-Marzán, L.M., de Abajo, F.J.G.: Modelling the optical response of gold nanoparticles. Chem. Soc. Rev. 37, 1792–1805 (2008)

Canet-Ferrer, J., Albella, P., Ribera, A., Usagre, J.V., Maier, S.A.: Hybrid magnetite–gold nanoparticles as bifunctional magnetic–plasmonic systems: three representative cases. Nanoscale Horiz. 2, 205–216 (2017)

Wang, H., Goodrich, G.P., Tam, F., Oubre, C., Nordlander, P., Halas, N.J.: Controlled texturing modifies the surface topography and plasmonic properties of Au nanoshells. J. Phys. Chem. B 109, 11083–11087 (2005)

Lupták, R., Fröhlich, K., Rosová, A., Hušeková, K., Ťapajna, M., Machajdı́k, D., Jergel, M., Espinós, J., Mansilla, C.: Growth of gadolinium oxide films for advanced MOS structure. Microelectron. Eng. 80, 154–157 (2005)

X-ray Photoelectron Spectroscopy, Ferraria, A.M., Carapeto, A.P., do Rego, A.M.B.: X-ray photoelectron spectroscopy: silver salts revisited. Vacuum 86, 1988–1991 (2012)

Bhunia, S.K., Jana, N.R.: Reduced graphene oxide-silver nanoparticle composite as visible light photocatalyst for degradation of colorless endocrine disruptors. ACS Appl. Mater. Interfaces. 6, 20085–20092 (2014)

Weaver, J.F., Hoflund, G.B.: Surface characterization study of the thermal decomposition of AgO. J. Phys. Chem. 98, 8519–8524 (1994)

Erol, M., Han, Y., Stanley, S.K., Stafford, C.M., Du, H., Sukhishvili, S.: SERS not to be taken for granted in the presence of oxygen. J. Amer. Chem. Soc. 131, 7480–7481 (2009)

Muddiman, D.C., Brockman, A.H., Proctor, A., Houalla, M., Hercules, D.M.: Characterization of polystyrene on etched silver using ion scattering and X-ray photoelectron spectroscopy: correlation of secondary ion yield in time-of-flight sims with surface coverage. J. Phys. Chem. 98, 11570–11575 (1994)

Turner, N., Single, A.: Determination of peak positions and areas from wide-scan XPS spectra. Surf. Interface Anal. 15, 215–222 (1990)

Eremenko, A., Smirnova, N., Gnatiuk, I., Linnik, O., Vityuk, N., Mukha, Y., Korduban, A.: Silver and gold nanoparticles on Sol-Gel TiO2, ZrO2, SiO2 surfaces: optical Spectra, photocatalytic activity, bactericide properties. In: Cuppoletti, J. (ed.) Nanocomposites and polymers with analytical methods. InTech, Rijeka, Croatia (2011)

Mihaylov, M., Ivanova, E., Hao, Y., Hadjiivanov, K., Gates, B.C., Knötzinger, H.: Oxidation by CO2 of Au0 species on La2O3-supported gold clusters chem. Chem. Comm. 175, 18973 (2008)

Kolb, H.C., Finn, M., Sharpless, K.B.: Click-chemie: diverse chemische funktionalität mit einer handvoll guter reaktionen. Angew. Chem. 113, 2056–2075 (2001)

Schweinfurth, D., Pattacini, R., Strobel, S., Sarkar, B.: New 1, 2, 3-triazole ligands through click reactions and their palladium and platinum complexes. Dalton Trans. 42, 9291–9297 (2009)

Grignon, N., Touraine, B., Durand, M.: 6 (5) Carboxyfluorescein as a tracer of phloem sap translocation. Am. J. Bot. 76, 871–877 (1989)

Acknowledgements

The authors would like to thank the University of Cologne (Excellence Program “Quantum Matter and Materials”), the “Deutsche Forschungsgemeinschaft” (DFG) and the “Deutscher Akademischer Austauschdienst” (DAAD) for financial support. S. Öz gratefully acknowledges the financial support provided by Merck KGaA (Darmstadt). In addition, we are thankful to Dipl.-Phys. Raphael German for Raman spectroscopy measurements, Mrs. Nurgül Tosun and Dr. Stefan Roitsch for SEM and TEM measurements.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing financial interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to urisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

40097_2018_252_MOESM1_ESM.docx

Supplementary material 1 (DOCX 1829 kb) EDX data for the Gd2O3@Ag, Gd2O3@Ag particles, SEM images and XPS data are presented

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Stadler, D., Siribbal, S.M., Gessner, I. et al. Asymmetric attachment and functionalization of plasmonic nanoparticles on ceramic interfaces. J Nanostruct Chem 8, 33–44 (2018). https://doi.org/10.1007/s40097-018-0252-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40097-018-0252-y