Abstract

Aflatoxins are a kind of mycotoxins that are mostly produced by a group of molds such as Aspergillus flavus and Aspergillus parasiticus. The studies on different parts of Iran showed that AFM1 infection of milk is higher than European Union’s standard. In this study, the specific aptamer with the carboxylic group at the end of 5′ and Fe3O4 nanoparticles with amine groups was synthesized. Morphological and structural qualities of Fe3O4 were determined by the Fourier-transform infrared spectrograph (FTIR), dynamic light scattering, scanning electron microscope, and X-ray diffraction devices. The specificity of the aptamer to AFM1 was investigated in adjacent of AFM1 and aflatoxin B1. Then, aptamers were attached to nanoparticles to improve synthetic qualities and to ease of its detachment. The attachment was approved by FTIR method. The complex (Fe3O4–APT) was then added to infected milk and after the proper time was detached from the milk using a magnet. The remained amount of AFM1 was attained in milk using high-performance liquid chromatography. Our result showed that this method for aflatoxin detoxification is much more effective than conventional methods based on recognition of AFM1 and their concentration in infected milk. This method is more applicable, faster, and cheaper highlighting its application in milk factories.

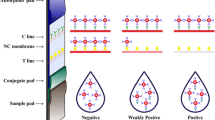

Graphical abstract

Similar content being viewed by others

Introduction

Aflatoxins are a kind of mycotoxins that are mostly produced by a group of molds such as Aspergillus flavus and Aspergillus parasiticus [1,2,3]. These poisons can be found in grain seeds, linen, nuts, and feedstuff of ambush, if cows pasturage from infected food, aflatoxin B1 (AFB1) hydroxylase by the hepatic enzyme of cytochrome P450 and changed to aflatoxin M1 (AFM1). AFM1 secrete to latescent cows and causes milk infection. AFM1 repel heating, pasteurization, and sterilization of the milk. Aflatoxins were categorized in 2B poisons category by International Agency for Research on Cancer (IARC) [2]. Moreover, it is considered as an element that causes mutant and also as a carcinogenic factor. The existence of the small amount of AFM1 for a long period of time in edible milk is important and causes liver cancer, Rey syndrome, chronic hepatitis, DNA trauma, and chromosome aberration [1]. Since milk is the main food of suckling, this group is more in danger of cancer and the diseases that are caused by these poisons. Not only in underdevelopment countries, but also in developed countries, aflatoxins are considered as a dilemma [2]. The food standards for AFM1 amount are dissimilar in different countries. The maximum amount of AFM1 in European community and Codex Alimentary must not be more than 50 ng in kilogram of crude milk and dairy products [4].

Different studies show that AFM1 is resistant to high and low temperatures. Some processes such as pasteurization, sterilization, and storing the milk in low temperatures for some months did not have any effects on aflatoxin content of infected milk. This kind of infection transmits from infected milk to other dairies such as cheese, yogurt, and yogurt drink [1, 2]. Today, analytical methods of analysis and detachment of aflatoxins including thin layer chromatography (TLC), high-performance liquid chromatography (HPLC), photoelectrochemical and electrochemical immunoassay, and enzyme-linked immunosorbent assay (ELISA) are used that are complicated, time-consuming, and expensive methods [1, 3, 5,6,7,8,9,10,11,12]. Therefore, it is important to find a method that is applicable, fast, inexpensive, and simple with high selectivity.

The studies on different parts of Iran showed that AFM1 infection of milk is higher than European Union’s standard. In a recent study which was conducted on pasteurized milk in Tehran, it was found that 78% of milk are infected which is higher than European Union and also this amount in city of Babol was reported four times more than the European Union’s standard [4].

Aptamers (APTs) are little functional oligonucleotides that are exclusive and incline to attach to target molecules such as drugs, proteins, poisons, and other organic and non-organic molecules. Aptamers synthesized simply in large amount by the chemical method and are resistant enough to biological temperature and can operate actions [1, 13]. The attachment of aptamer to nanomagnetic particles improves its synthetic qualities, increases the attachment of target molecules, and eases the detachment of aptamer complex from target molecule [1, 14].

In this study, the specific aptamer was synthesized and its specificity to AFM1 was investigated in adjacent to AFM1 and AFB1. Aptamers were attached to nanoparticles via crosslinking of –COOH and –NH2 to improve synthetic qualities and to ease of its detachment. The infected milk was placed in adjacent to Fe3O4–APT and the complex was removed by the magnet. The concentration of the remained AFM1 in milk was then measured by HPLC method.

Materials and methods

Synthesis of magnetic nanoparticles of iron oxide consisting of amine group

The nanoparticles of Fe3O4 were produced by co-precipitation method. 2.7 g of FeCl3·6H2O and 0.9941 g of FeCl2·4H2O were solvated in 20–50 ml of H2O. Then, it was put into a mechanical mixer for 20 min. 30 ml of soluble ammonia 25% was added to soluble for 30 min in drop form. It was again put into the mechanical mixer for 6 h and in 80 °C and pH was then measured on the 5th hour. Ammonia was added to regulate the pH between 11 and 13. Therefore, Fe3O4 synthesized and iron oxide silicified. Afterwards, 40 cc ethanol was added to synthesized Fe3O4 and was put in the mixer for 1 h in temperature of 40 °C. Then, 10 cc of Tetraethyl orthosilicate (SiC8H20O4) was added and was put in mixer for 1 h at 40 °C. The obtained mixture was rinsed with water and ethanol and its pH reached to 7. Continuously, it was dried at 80 °C in 12 h and Fe3O4–SiO2 was acquired. One milliliter 3-aminopropyl trimethoxy silane and 50 cc toluene were added to 1 mg of Fe3O4–SiO2 and they were put in the mixer for 18 h at 60 °C. Then, it was washed four times by toluene and dried [15].

Determination of synthesized nanoparticles’ qualities

For investigation of synthesized nanoparticles’ efficiency, they were scattered in an equal environment that was a dingy suspension. Afterwards, a magnet was placed near the rim of the plate [16]. After passing of 2 min, the nanoparticles assembled completely on the rim of the plate and the suspension became transparent (Fig. 1).

A number of absorption changes were investigated by the spectrophotometric method in the range of 300–700 nm for ethanol and surfaced soluble. Moreover, the surfaced coverage of nanoparticles was measured using Fourier-transform infrared spectrograph (FTIR) and X-ray diffraction (XRD). The method of dynamic light scattering (DLS) and scanning electron microscope (SEM) was then used for determination of synthesized nanoparticles’ dimensions.

Selection of specific aptamer, the synthesis of aptamer, and its related primers

The specific aptamer of AFM1 was synthesized as described by Malhotra and et al. [17]. Among the 15 suggested sequences, the one had the least dissociation constant (K d) was chosen (35.6 ± 2.9 nM) and synthesized by Technology Gene company that its sequence is as follows:

5′ATCCGTCACACCTGCTCTATCCGTCACACCTGCTCTGACGCTGGGGTCGACCCGGATGGTGTTGGCTCCCGTAT3′.

In addition, the sequence of primers of forward and reverse was designed and synthesized by Technology Gene Company as follows:

F: 5′ATCCGTCACACCTGCTCT3′.

R: 5′ATACGGGAGCCAACACCA3′.

Afterwards, carboxylic with C10 linker was attached to the end of 5′ aptamers by Danish Tag Copenhagen Company.

Amplification of the specific aptamer by RT-PCR

The blending of the reaction of RT-PCR was provided in amount of 0.1 µM from forward primer, 0.1 µM of reverse primer, 1–10 ng of aptamer, and 10 µl from Master Mix (Zist Fanavari Pishgam Company, Tehran, Iran). Diethyl pyrocarbonate (DEPC) water was then added to reach the 20 µl volume. The amplification of primers was administered by thermocycler device at (1) 95 °C for 4 min, (2) 95 °C for 0.3 min, (3) 55 °C for 0.05 min, (4) 72 °C for 0.15 min, and (5) 72 °C for 10 min. The phases of 2–4 iterated for 30 cycles [17]. Ten microliters of the reaction product were electrophoresed on agarose gel 2% to be sure about amplification of aptamer.

Attachment of specific aptamer to magnetic nanoparticles

The conjugation of aptamers to nanoparticles was accomplished via crosslinking of –COOH and –NH2. EDC/NHS technique was used to activate the –COOH groups of aptamers. Briefly, 50 µl of aptamer (10 µg/ml) were incubated with 100 µl of N-hydroxysuccinimide (NHS) (10 µg/ml) for 15 min at room temperature and were mixed smoothly by the mechanical mixer. Moreover, the activated aptamers were incubated for 2 h with 50 µl of nanoparticles (1 µg/ml) at room temperature. The aptamers which are attached to nanoparticles were obtained, rinsed and stored in DEPC water at 4 °C [18]. The bio-conjugation of the aptamer to nanoparticles was investigated by electrophoresis on 2% agarose gel.

Using of Fe3O4–APT in elimination of AFM1 in infected milk

The concentration of AFM1 in infected milk was measured by HPLC method to investigate the power of Fe3O4–APT in the elimination of AFM1 in infected milk. The concentration of aflatoxin reached to 100 PPT based on the obtained concentration of AFM1. The infected milk was placed in adjacent of 50 µl (1 µg/ml) Fe3O4–APT and the complex was removed by the magnet. The concentration of the remained AFM1 in milk was then measured by HPLC method. The specificity of the designed aptamer was investigated by AFB1. Fe3O4–APT was added to infected milk to AFB1 and the concentration of remained AFB1 in milk was measured by HPLC method.

Results

Determination of synthesized nanoparticles qualities

The efficiency of synthesized nanoparticles was investigated. The obtained nanoparticles were scattered in an equal environment that was a dingy suspension. A magnet was then placed near the rim of the plate. Following of 2 min, the nanoparticles assembled completely on the rim of the plate and the suspension became clear. This magnetic characteristic showed that synthesized nanoparticles can be used as a target to be collected by the magnet.

A number of absorption changes were investigated by the spectrophotometric method in a range of 300–700 nm for ethanol and supernatant. The obtained amounts did not show the significant difference between ethanol and supernatant (Fig. 2). The size of the particles was measured by DLS (Fig. 3) and SEM (Fig. 4). The size of Fe3O4 particles was almost 70 nm and the size of Fe3O4–SiO2–NH2 particles was 100 nm. The surfaced coverage of nanoparticles was measured using IR and XRD (Figs. 5, 6). In the XRD pattern, there are six characteristic peaks for Fe3O4 (2θ = 21.25°, 37.29°, 43.73°, 52.56°, 65.09°, 69.73°, and 76.81°). These are related to six crystal faces. As shown in Fig. 6, the XRD pattern of Fe3O4–SiO2 [Fig. 6(2)] and Fe3O4–SiO2–NH2 (Fig. 3) matches with the peaks of Fe3O4 and this shows that after surface modification of Fe3O4, the crystalline structure of Fe3O4 does not change [19,20,21]. In IR spectrum, the obtained measures had four bands in areas of 3389, 2927, 1095, and 578 cm−1 that are, respectively, related to NH2 group free flexibility vibration, tensional vibrations of C–H, SiO, and FeO. The changed absorption peaks were found in 3389 cm−1 that shows the successful entrance of amine to the surface of synthesized magnetic nanoparticles [22].

Attachment of carboxylic group to the end of 5′ specific aptamer

The results of mass spectroscopy showed that the carboxylic group was properly attached to the aptamer. The molecular weight of aptamer before and after attachment of carboxylic was 22,624 and 22,874.84 g/mol, respectively. These data showed good performance of attachment between carboxylic group and aptamer (Fig. 7).

Aptamer-specific amplification by RT-PCR method and attachment to magnetic nanoparticles

Ten microliters of the reaction product were electrophoresed on agarose gel 2% to verify the amplification of aptamer (Fig. 8). The bio-conjugation of the aptamer to nanoparticles was then investigated by electrophoresis on 2% agarose gel (Fig. 8).

Using of Fe3O4–APT in elimination of AFM1 in infected milk

The concentration of AFM1 in pasteurized milk was measured by HPLC to investigate the power of Fe3O4–APT in the elimination of AFM1 in infected milk. The initial concentration of AFM1 in pasteurized milk was 25 PPT (Fig. 9a). The aflatoxin’s concentration reached to 100 PPT by adding 70 PPT (Fig. 9b) and infected milk was placed in adjacent of 50 µl Fe3O4–APT (1 µg/ml). Then, Fe3O4–APT was removed by the magnet and the concentration of the remained AFM1 in milk was measured by HPLC method. The late measured concentration was 5 PPT (Fig. 9c) which it is less than the initial concentration.

The specificity of the designed aptamer was investigated by AFB1. Fe3O4–APT was added to infected milk to AFB1 and the concentration of remained AFB1 in milk was measured by HPLC method. The obtained results showed the high specificity of the aptamer to detoxify AFM1 in milk (Fig. 10). The concentration of AFB1 in milk was measured before and after addition AFB1 to milk to be more confident. Our result did not show any changes in concentration of AFB1, and therefore, introduced complex was specific for AFM1.

Discussion

The occurrence of aflatoxin in food is a serious global health problem, particularly in developing countries. Aflatoxins are well documented as cancer potency factors as 4.6–28.2% of annual hepatocarcinoma cases worldwide are caused by these toxins [23, 24]. The presence of AFM1 in milk and other dairy products is a concern throughout the world and many countries have set threshold limits for milk used by adults and infants. Despite a considerable progress in food industry in Iran during the past two decades, a few reliable data are available on contamination levels of milk and other dairy products with AFM1. The earliest study in Iran dates back to 1982, in which 52 liquid milk samples from Tehran showed to be contaminated with AFM1, ranging from 23 to 3000 µl/l [25]. In addition, in another study on pasteurized milk samples from Tehran, AFM1 contamination showed to be above the threshold (50 ng/kg) set by the European Union [25]. However, a validated HPLC analysis of milk samples from five different regions in Iran (Gorgan, Hamedan, Rasht, Shiraz, and Tehran) showed that the AFM1 contamination levels were much lower than those obtained by quantitative ELISA [26].

Detoxification of aflatoxin at low concentrations is too hard and usually requires long induction times before further analysis. Magnetic nanoparticles have been utilized for magnetic capture of aflatoxins in the sample milk giving aid to detoxification. Magnetic nanoparticles are usually functionalized with bio-recognition molecules, such as antibody, aptamers, bioprotein, and carbohydrates for a specific interaction, [14, 27,28,29,30], which allow to aflatoxin detoxification and targeting. Here, we report the utilization of amine-functionalized magnetic nanoparticles for rapid, inexpensive, and effective capture of AFM1.

The Aptamer is a single-stranded oligonucleotide with remarkable recognition feature. The high affinity of aptamers is related to the notable K d ranging from levels between the aptamer and its target. [31]. The detoxification of aflatoxin M1 in milk depends on precise and reliable analytical. Although HPLC, TLC, and more recently, ELISA are commonly used for AFM1 analysis, most of these methods involve expensive instruments and time-consuming [32]. Aptamers offer another opportunity as a simple, safe, rapid, and robust technique and this method has been testing in many other systems with success [13, 33, 34]. In this study, those aptamers that were attached to ferrous oxide nanoparticles were used for wiping off the toxic effect of AFM1. The synthesized nanoparticles had the dimensions of 70–100 nm (Fig. 3). The properties of nanoparticles were determined by SEM, XRD, and IR that show the correctitude of synthesizing of nanoparticles (Figs. 4, 5, 6).

The selected aptamer had dissociation constant equal 35.6 ± 2.9 nM. The obtained figures from electrophorese of agarose gel showed the proper attachment of aptamer to the nanoparticles (Fig. 8). The attached nanoparticles were added to infected milk by AFM1 showed its capability in the elimination of milk’s infection and decreased the concentration of AFM1 from 100 to 5 PPT. Based on European community and Codex Alimentary’s standard, the maximum concentration of AFM1 must not be more than 50 ng in each kilogram of crude milk and dairy [4]; therefore, the obtained concentration is in accepted range.

The addition of AFB1 to milk and aptamer inability in its detoxification showed the high sensitivity of aptamer in detoxification of AFM1 from infected milk. A new method based on aflatoxin detoxification was introduced which is more applicable, faster, and cheaper highlighting its potential of usefulness to be applied in milk factories.

Conclusions

The conducted researches on milk magnify its role in AFM1 transformation to the consumers and threatening their health and advance the attention to the hygienic quality of produced milk. Therefore, in the present study, a new method was introduced with high specificity and sensitivity for detoxification of milk that can be used in factories which produce pasteurized milk. Our method is much more effective than conventional methods based on recognition of AFM1 and their concentration in infected milk.

References

Nguyen, B.H., Tran, L.D., Do, Q.P., Nguyen, H.L., Tran, N.H., Nguyen, P.X.: Label-free detection of aflatoxin M1 with electrochemical Fe3O4/polyaniline-based aptasensor. Mater. Sci. Eng. C 33(4), 2229–2234 (2013)

Prandini, A., Tansini, G., Sigolo, S., Filippi, L., Laporta, M., Piva, G.: On the occurrence of aflatoxin M1 in milk and dairy products. Food Chem. Toxicol. 47(5), 984–991 (2009)

Xiulan, S., Xiaolian, Z., Jian, T., Xiaohong, G., Jun, Z., Chu, F.: Development of an immunochromatographic assay for detection of aflatoxin B1 in foods. Food Control 17(4), 256–262 (2006)

Sefidgar, S., Mirzae, M., Assmar, M., Naddaf, S.: Aflatoxin M1 in pasteurized milk in Babol city, Mazandaran Province, Iran. Iran. J. Public Health 40(1), 115–118 (2011)

Kang’ethe, E., Lang’a, K.: Aflatoxin B1 and M1 contamination of animal feeds and milk from urban centers in Kenya. Afr. Health Sci. 9(4), 218–226 (2009)

Mosiello, L., Lamberti, I.: Biosensors for aflatoxins detection. Available from: http://www.intechopen.com/books/aflatoxins-detection-measurement-and-control/biosensors-for-aflatoxinsdetection. Accessed 23 June 2017

Piermarini, S., Volpe, G., Micheli, L., Moscone, D., Palleschi, G.: An ELIME-array for detection of aflatoxin B1 in corn samples. Food Control 20(4), 371–375 (2009)

Shim, W., Wong, P.: Stem cell cardiomyoplasty: state-of-the-art. Ann. Acad. Med. Singap. 33(4), 451–460 (2004)

Lin, Y., Zhou, Q., Lin, Y., Tang, D., Niessner, R., Knopp, D.: Enzymatic hydrolysate-induced displacement reaction with multifunctional silica beads doped with horseradish peroxidase–thionine conjugate for ultrasensitive electrochemical immunoassay. Anal. Chem. 87(16), 8531–8540 (2015)

Lin, Y., Zhou, Q., Tang, D., Niessner, R., Yang, H., Knopp, D.: Silver nanolabels-assisted ion-exchange reaction with CdTe quantum dots mediated exciton trapping for signal-on photoelectrochemical immunoassay of mycotoxins. Anal. Chem. 88(15), 7858–7866 (2016)

Lin, Y., Zhou, Q., Tang, D., Niessner, R., Knopp, D.: Signal-on photoelectrochemical immunoassay for aflatoxin B1 based on enzymatic product-etching MnO2 nanosheets for dissociation of carbon dots. Anal. Chem. 89(10), 5637–5645 (2017)

Lin, Y., Lin, Y., Tang, D., Chen, G., Tang, D.: Simple and sensitive detection of aflatoxin B 1 within five minute using a non-conventional competitive immunosensing mode. Biosens. Bioelectron. 74, 680–686 (2015)

Chen, J., Fang, Z., Liu, J., Zeng, L.: A simple and rapid biosensor for ochratoxin A based on a structure-switching signaling aptamer. Food Control 25(2), 555–560 (2012)

Qiu, Z., Shu, J., Tang, D.: Bioresponsive release system for visual fluorescence detection of carcinoembryonic antigen from mesoporous silica nanocontainers mediated optical color on quantum dot-enzyme-impregnated paper. Anal. Chem. 89(9), 5152–5160 (2017)

Xu, J., Ju, C., Sheng, J., Wang, F., Zhang, Q., Sun, G., Sun, M.: Synthesis and characterization of magnetic nanoparticles and its application in lipase immobilization. Bull. Korean Chem. Soc. 34(8), 2408–2412 (2013)

Du, X., He, J., Zhu, J., Sun, L., An, S.: Ag-deposited silica-coated Fe3O4 magnetic nanoparticles catalyzed reduction of p-nitrophenol. Appl. Surf. Sci. 258(7), 2717–2723 (2012)

Malhotra, S., Pandey, A.K., Rajput, Y.S., Sharma, R.: Selection of aptamers for aflatoxin M1 and their characterization. Mol. Recognit. 27(8), 493–500 (2014)

Yu, C., Hu, Y., Duan, J., Yuan, W., Wang, C., Xu, H., Yang, X.D.: Novel aptamer–nanoparticle bioconjugates enhances delivery of anticancer drug to MUC1-positive cancer cells in vitro. PLoS One 6(9), e24077 (2011)

Zahoor, M., Ali Khan, F.: Aflatoxin B1 detoxification by magnetic carbon nanostructures prepared from maize straw. Desalin. Water Treat. 57(25), 11893–11903 (2016)

Muneeb Ur Rahman Khattak, M., Zahoor, M., Muhammad, B., Khan, F.A., Ullah, R., AbdEI-Salam, N.M.: Removal of heavy metals from drinking water by magnetic carbon nanostructures prepared from biomass. J. Nanomater. 2017, (2017). https://doi.org/10.1155/2017/5670371

Zahoor, M., Khan, F.A.: Adsorption of aflatoxin B1 on magnetic carbon nanocomposites prepared from bagasse. Arab. J. Chem. (2014) (In Press)

Xu, J., Ju, C., Sheng, J., Wang, F., Zhang, Q., Sun, G., Sun, M.: Synthesis and characterization of magnetic nanoparticles and its application in lipase immobilization. Bull. Korean Chem. Soc. 34(8), 2409–2412 (2013)

Kazemi Darsanaki, R., Mohammad, D.C.M., Azizollahi, A.M.: Aflatoxin M1 contamination in milk and milk products in Iran: a review. J. Chem. Health Risks 3(3), 13–20 (2013)

Han, Z., Zheng, Y., Luan, L., Cai, Z., Ren, Y., Wu, Y.: An ultra-high-performance liquid chromatography-tandem mass spectrometry method for simultaneous determination of aflatoxins B1, B2, G1, G2, M1 and M2 in traditional Chinese medicines. Anal. Chim. Acta 664(2), 165–171 (2010)

Karimi, G., Hassanzadeh, M., Teimuri, M., Nazari, F., Nili, A.: Aflatoxin M1 contamination in pasteurized milk in Mashhad, Iran. Iran. J. Pharm. Sci. 3(3), 153–156 (2007)

Tajkarimi, M., Aliabadi, F.S., Nejad, M.S., Pursoltani, H., Motallebi, A., Mahdavi, H.: Seasonal study of aflatoxin M1 contamination in milk in five regions in Iran. Int. J. Food Microbiol. 116(3), 346–349 (2007)

Huang, Y.F., Wang, Y.F., Yan, X.P.: Amine-functionalized magnetic nanoparticles for rapid capture and removal of bacterial pathogens. Environ. Sci. Technol. 44(20), 7908–7913 (2010)

Gao, Z., Xu, M., Hou, L., Chen, G., Tang, D.: Magnetic bead-based reverse colorimetric immunoassay strategy for sensing biomolecules. Anal. Chem. 85(14), 6945–6952 (2013)

Tang, J., Tang, D., Niessner, R., Chen, G., Knopp, D.: Magneto-controlled graphene immunosensing platform for simultaneous multiplexed electrochemical immunoassay using distinguishable signal tags. Anal. Chem. 83(13), 5407–5414 (2011)

Zhang, B., Liu, B., Tang, D., Niessner, R., Chen, G., Knopp, D.: DNA-based hybridization chain reaction for amplified bioelectronic signal and ultrasensitive detection of proteins. Anal. Chem. 84(12), 5392–5399 (2012)

Feng, C., Dai, S., Wang, L.: Optical aptasensors for quantitative detection of small biomolecules: a review. Biosens. Bioelectron. 59, 64–74 (2014)

Trucksess, M.W., Pohland, A.E.: Mycotoxin protocols (Methods in molecular biology)). Pohland © Humana Press Inc., Totowa, NJ (2001)

Shim, W.B., Mun, H., Joung, H.A., Ofori, J.A., Chung, D.H., Kim, M.G.: Chemiluminescence competitive aptamer assay for the detection of aflatoxin B1 in corn samples. Food Control 36(1), 30–35 (2014)

Hu, X., Tulsieram, K.L., Zhou, Q., Mu, L., Wen, J.: Polymeric nanoparticle–aptamer bioconjugates can diminish the toxicity of mercury in vivo. Toxicol. Lett. 208(1), 69–74 (2012)

Acknowledgements

This work was financially supported by Grant No. 93010102 from Iran National Science Foundation (INSF) to PA.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to urisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Javani Jouni, F., Zafari, J., Abdolmaleki, P. et al. Aflatoxin M1 detoxification from infected milk using Fe3O4 nanoparticles attached to specific aptamer. J Nanostruct Chem 8, 13–22 (2018). https://doi.org/10.1007/s40097-017-0250-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40097-017-0250-5