Abstract

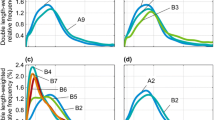

Two instrumental test methods—FibreShape flatbed scanning and Dia-Stron laser diffraction technology—are used for diameter analysis of lignocellulosic hollow fibrous material produced from biomass of two different canola cultivars, 5440 and 45H29. Although FibreShape is capable of working with any size of dataset, a larger dataset would generate the optimum analytical test results. Interestingly, FibreShape operates faster and saves time. On the contrary, Dia-Stron is restricted to data size, due to the limitation of its cassette slots for specimen storage. Further, this machine is slow in processing—which takes hours to complete—and the presence of microscopic cracks on the fibre surface will generate erratic test results for that specific fibre, which, however, is not notified by the computing system until the test-run is completed for all the loaded fibres. Such a practice might become challenging due to research time constraints. The requirement of consistent gauge length is another limitation of this laser diffraction test method to test staple fibres and filaments unlike the FibreShape. Upon testing the 45H29 cultivars, FibreShape and Dia-Stron exhibited a smaller difference of 12 µm (= 88.26 − 76.26) in fibre diameters between their test results, whereas the difference was as large as 44.6 µm (= 120.29 − 75.69) for the 5440 fibres. However, the statistical t-test did not identify any significant variation between the observed test results obtained from FibreShape and Dia-Stron as p = 0.34 > α = 0.05 (95% confidence interval). The current study favours using FibreShape over Dia-Stron for analysing textile fibre diameters due to the versatility of working capacity with any specimen shape or configuration, size of a dataset, speed of conducting a test, flexibility of sample selection and preparatory processes, and gauge-length independence.

Reproduced with permission from our previous work [2]. Copyright 2019, TRJ, SAGE publications)

Similar content being viewed by others

Availability of data and material

All data generated or analyzed during this study are included in this article.

Abbreviations

- SF:

-

Single fibre

- BF:

-

Bundle fibre (mixed fibres containing both single fibres and overlapped fibres)

- Q1:

-

Quartile 1

- Q2:

-

Quartile 2

- Q3:

-

Quartile 3

- Q4:

-

Quartile 4

References

K. Chakma, Extraction Efficiency Quality and Characterization of Typha Latifolia L. Fibres for Textile Applications L. Fibres for Textile Applications (University of Manitoba, Winnipeg, 2019).

I.I. Shuvo, M. Rahman, T. Vahora, J. Morrison, S. DuCharme, L.-P. Choo-Smith, Producing light-weight bast fibers from canola biomass for technical textiles. Text. Res. J. 90, 11–12 (2019)

S.J. Lennon, L.D. Burns, Diversity of research in textiles, clothing, and human behavior: the relationship between what we know and how we know. Cloth. Text. Res. J. 18(4), 213–226 (2000)

S.J. Lennon, K.K.P. Johnson, J.H. Park, Research trends in textiles and clothing: an analysis of three journals, 1980–1999. Fam. Consum. Sci. Res. J. 30(2), 117–139 (2001)

R. Kozłowski (ed.), Handbook of Natural Fibres, vol. 1 (Woodhead Publication, Cambridge, 2012)

R.M. Trüeb, D. Tobin, Aging Hair (Springer, Berlin Heidelberg, 2010).

H.D. Cochran, Analysis of Carbon Fiber Characterization Techniques (University of Tennessee, Knoxville, 2008).

FibreShape. IST AG Fibre and Particel Analysis. FibreShape (2020)

R. Kozłowski (ed.), Handbook of Natural Fibres, vol. 2 (Woodhead Publication, Cambridge, 2012)

G.P. Sevenhuysen, M. Rahman, Textile Fibres and Textiles from Brassica Plants. Patent no. WO2015039243 A1 (2016)

M.R.I. Khan, Evaluation of Brassica fibre for textile and spinning properties (master’s thesis). University of Manitoba, Winnipeg, Canada (2016)

I.I. Shuvo, M. Rahman, R. Duncan, J. Mackinnon. A critical review on the cottonization of bast fibre. Poster presented at the Canadian Society for Bioengineering Conference (CSBE), CSBE17143, Winnipeg, Canada (2017)

Z. Jankauskienė, B. Butkutė, E. Gruzdevienė, J. Cesevičienė, A.L. Fernando, Chemical composition and physical properties of dew- and water-retted hemp fibers. Ind. Crops Prod. 75, 206–211 (2015)

S. Grigoryev, Hemp of Russian northern regions as a source of spinning fibers. J. Ind. Hemp 10(2), 105–114 (2005)

M. El-Messiry, S.A.M. Abd-Ellatif, Prediction of extra-long Egyptian yarn tenacity using fibre quality index (MFQI). Fibres Text. East. Eur. 21(3), 31–35 (2013)

L.C. Deleuran, P.K. Flengmark, Yield potential of hemp (cannabis sativa L.) cultivars in Denmark. J. Ind. Hemp 10(2), 19–31 (2006)

H.T.H. Cromack, The effect of cultivar and seed density on the production and fibre content of Cannabis sativa in southern England. Ind. Crops Prod. 7(2–3), 205–210 (1998)

D.J. Carr, N.M. Cruthers, R.M. Laing, B.E. Niven, Fibers from three cultivars of New Zealand flax (Phormium tenax). Text. Res. J. 75(2), 93–98 (2005)

A.E. Brown, H.S.S. Sharma, D.L.R. Black, Relationship between pectin content of stems of flax cultivars, fungal cell wall-degrading enzymes and pre-harvest retting. Ann. Appl. Biol. 109(2), 345–351 (1986)

Acknowledgements

The authors would like to thank Dr. Mashiur Rahman, Dr. Robert Duncan, Dr. Lin-P’ing Choo-Smith, and Garett Keith.

Funding

The project was supported by University of Manitoba, MITACS Canada, and CIC Engineering, Canada.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Ethical approval

This research does not contain any studies on human participants or animals performed by the author.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shuvo, I.I., DuCharme, S. Inter-Comparison of Two Instrumental Test Methods for Diameter Analysis of Fibre Materials: Scope and Challenges. J. Inst. Eng. India Ser. E 102, 127–136 (2021). https://doi.org/10.1007/s40034-021-00206-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40034-021-00206-4