Abstract

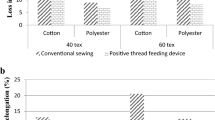

During high-speed industrial lockstitch sewing, repeated stresses and strains on the needle thread adversely influence its sewing performance. The sewing performance of threads is affected by reduction in its tensile strength. For maximum strength retention of needle thread, a positive thread feeding device is developed, which is independent of the fabric feed mechanism as in conventional sewing, where sewing thread is pulled from the cone directly wherein the thread feed is controlled by spring disc tensioner and needle movement. The dynamic needle thread tension is measured above the needle bar using strain gauge load cell. The load cell converts force or weight into electrical signal. The highest thread tension (stitch tightening tension) occurs when the take-up lever pulls the required thread amount through the spring disc tensioner. Positive thread feeding of needle thread lowers the tightening tension (peak tension), and hence, strength retention of needle thread is observed. In this paper, the breaking force of mercerized cotton needle thread at various sewing variables, viz. fabric density, number of fabric layers, and stitch length, is studied during conventional sewing and also by using positive thread feeding device. The loss in breaking force increases with the increase in fabric density, whereas it decreases as the number of fabric layers and stitch length increased.

Similar content being viewed by others

References

A. Rudolf, J. Gersak, Study of the relationship between deformation of the thread and built-in fibres. Int. J. Cloth. Sci. Tech. 13(3–4), 289–300 (2001)

D.J. Lojen, J. Gersak, Thread loadings in different measuring positions on the sewing machine. Tex. Res. J. 75(6), 498–506 (2005)

F.B.N. Ferriera, S.C. Harlock, P. Grosberg, A study of thread tensions on lock stitch sewing machine. Part-I. Int. J. Cloth. Sci. Tech. 6(1), 14–19 (1994)

R.H. Crow, N.H. Chamberlain, The performance of sewing threads in industrial sewing machines, England, (Report No. 21). The Clothing Institute, London (1969)

J. Gersak, B. Knez, Reduction in thread strength as a cause of loading in sewing process. Int. J. Cloth. Sci. Tech. 3(4), 6–12 (1991)

G. Sundaresan, P.K. Hari, K.R. Salhotra, Strength reduction in sewing threads during high speed sewing in an industrial lockstitch machine: part I mechanism of thread strength reduction. Int. J. Cloth. Sci. Tech. 9(5), 334–345 (1997)

G. Sundaresan, K.R. Salhotra, P.K. Hari, Strength reduction in sewing threads during high speed sewing in an industrial lockstitch machine: part II effect of thread and fabric properties. Int. J. Cloth. Sci. Tech. 10(1), 64–79 (1998)

A. Rudolf, J. Gersak, The influence of thread twist on alteration in fibers’ mechanical properties. Tex. Res. J. 76(2), 134–144 (2006)

V.K. Midha, A. Mukhopadhyay, R. Chattopadhyay, V.K. Kothari, Studies on the changes in tensile properties of sewing thread at different sewing stages. Tex. Res. J. 79(13), 1155–1167 (2009)

V.K. Midha, V.K. Kothari, R. Chattopadhyay, A. Mukhopadhyay, Effect of high speed sewing on the tensile properties of sewing thread at different stages of sewing. Int. J. Cloth. Sci. Tech. 21(4), 217–238 (2009)

V.K. Midha, R. Chattopadhyay, V.K. Kothari, A. Mukhopadhyay, Effect of process and machine parameters on changes in tensile properties of threads during high speed industrial sewing. Tex. Res. J. 80(6), 491–507 (2010)

V.K. Midha, V.K. Kothari, R. Chattopadhyay, A. Mukhopadhyay, Effect of workwear fabric characteristics on the changes in tensile properties of sewing threads after sewing. J. Engg. Fib. Fab. 5(1), 31–38 (2010)

V.K. Midha, V.K. Kothari, R. Chattopadhyay, A. Mukhopadhyay, A neural network model for prediction of strength loss in threads during high speed industrial sewing. Fib. Poly. 11(4), 661–668 (2010)

D.S. Wesley, R.S. Rengasamy, Changes in tensile properties of needle thread in lock stitch sewing. Fib. Poly. 18(2), 390–399 (2017)

V.K. Midha, A. Mukhopadhyay, R. Kaur, An approach to seam strength prediction using residual thread strength. Res. J. Tex. App. 15(3), 75–85 (2011)

I. Ajiki, T.J. Mahar, R. Postle, Measurement of structural balance and mechanical properties of seamed fabrics, in Objective Evaluation of Apparel Fabrics, ed. by R. Postle, S. Kawabata, M. Niwa (Tex. Mach. Soc. Japan, Osaka, 1983), pp. 349–358

A. Chen, H. Zou, R. Du, Modeling of industrial sewing machines and the balancing of thread requirement and thread supply. J. Tex. Ins. 92(3), 256–268 (2001)

C.M.C. Dorkin, N.H. Chamberlain, The facts about needle heating, England, (Report No. 13). The Clothing Institute, London (1963)

R.A. Khan, S.P. Hersh, P.L. Grady, Simulation of needle-fabric interactions in sewing operations. Tex. Res. J. 40(6), 489–498 (1970)

F.N. Hurt, D.J. Tyler, An investigation of needle heating and associated problems in machine sewing—I, England (Report No. 19). HATRA Research centre for Knitting, Dyeing and Making-up, Nottingham (1971)

F.N. Hurt, D.J. Tyler, An investigation of needle heating and associated problems in machine sewing—III, England (Report No. 21). HATRA Research centre for Knitting, Dyeing and Making-up, Nottingham (1972)

Q. Li, E. Liasi, R. Du, A study on the needle heating in heavy industrial sewing—Part 2: finite Element Analysis and experimental verification. Int. J. Cloth. Sci. Tech. 13(5), 351–367 (2001)

E. Liasi, R. Du, D. Simon, J.B. Dimitrejevic, F. Liburdi, Heating of an industrial sewing needle. Int. J. Cloth. Sci. Tech. 11(5), 300–314 (1999)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Midha, V.K., Gupta, V. & Mukhopadhyay, A. Impact of Positive Thread Feeding for High-Speed Industrial Lockstitch Sewing Machines: Part I Development of Device. J. Inst. Eng. India Ser. E 100, 71–79 (2019). https://doi.org/10.1007/s40034-019-00136-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40034-019-00136-2