Abstract

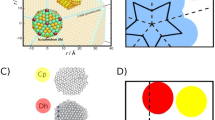

Phase diagram was predicted for Cu–Ni nanoalloy system using regular solution considering various models with and without segregation. Phase diagrams for nanoparticles are affected by the melting point of nanoparticles, and various models are available to predict the melting point for nanoparticles. Hence, choosing the right model helps in accurate nanophase diagram predictions. Three models are considered to predict the melting point of nanoparticles and phase diagrams. Thermodynamic model, enthalpy and entropy model and crystal structure models were compared for their melting points and phase diagram predictions. These three models were then compared with experimental results carried out by Sopousek et al. for a 26 nm particle size. It was found that for a 11.1 Wt% Ni nanoalloy, thermodynamic model accurately predicts the phase diagram with an error of 0.09% compared to enthalpy and entropy model. Thermodynamic model is also known as the surface-phonon instability model which considers various factors like surface phonons, atoms and intrinsic defects in the nanoparticle and hence accurately predicts the melting point and the phase diagram. Further segregation effects were also considered, and for the first time, a comparison between three models is reported which shows significant merging of solidus and liquidus curves in thermodynamic model and enthalpy and entropy model using William–Nason’s model.

Similar content being viewed by others

References

W.A. Jesser, G.J. Shiflet, G.L. Allen, J.L. Crawford, Equilibrium phase diagrams of isolated nano-phases. Mater. Res. Innov. (1999). https://doi.org/10.1007/s100190050087

N. Saunders, A.P. Miodownik, Evaluation of glass forming ability in binary and ternary metallic alloy systems—an application of thermodynamic phase diagram calculations. Mater. Sci. Technol. (2014). https://doi.org/10.1179/mst.1988.4.9.768

H.J. Seifert, H.L. Lukas, F. Aldinger, Development of Si–B–C–N ceramics supported by phase diagrams and thermochemistry. Ber. Der Bunsenges. Für Phys. Chem. (2012). https://doi.org/10.1002/bbpc.19981020942

N.A. Pertsev, A.G. Zembilgotov, A.K. Tagantsev, Effect of mechanical boundary conditions on phase diagrams of epitaxial ferroelectric thin films. Phys. Rev. Lett. (1998). https://doi.org/10.1103/physrevlett.80.1988

R. Klenk, T. Walter, H.W. Schock, D. Cahen, A model for the successful growth of polycrystalline films of CuInSe2 by multisource physical vacuum evaporation. Adv. Mater. (1993). https://doi.org/10.1002/adma.19930050209

G. Inden, The role of magnetism in the calculation of phase diagrams. Phys B+C (1981). https://doi.org/10.1016/0378-4363(81)91004-4

D. Li, L. Liu, Y. Zhang, C. Ye, X. Ren, Y. Yang et al., Phase diagram calculation of high chromium cast irons and influence of its chemical composition. Mater. Des. (2009). https://doi.org/10.1016/j.matdes.2008.04.061

A. San-Miguel, Nanomaterials under high-pressure. Chem. Soc. Rev. (2006). https://doi.org/10.1039/b517779k

V. Bobnar, Z. Kutnjak, R. Pirc, A. Levstik, Electric-field-temperature phase diagram of the relaxor ferroelectric lanthanum-modified lead zirconate titanate. Phys. Rev. B Condens. Matter Mater. Phys. (1999). https://doi.org/10.1103/physrevb.60.6420

M. Wautelet, On the shape dependence of the melting temperature of small particles. Phys. Lett. Sect. Gen. Solid State Phys. 246, 341–342 (1998). https://doi.org/10.1016/S0375-9601(98)00538-6

M. Wautelet, J.P. Dauchot, M. Hecq, On the phase diagram of non-spherical nanoparticles. J. Phys. Condens. Matter (2003). https://doi.org/10.1088/0953-8984/15/21/313

R. Vallée, M. Wautelet, J.P. Dauchot, M. Hecq, Size and segregation effects on the phase diagrams of nanoparticles of binary systems. Nanotechnology (2001). https://doi.org/10.1088/0957-4484/12/1/312

M. Wautelet, J.P. Dauchot, M. Hecq, Size effects on the phase diagrams of nanoparticles of various shapes. Mater. Sci. Eng. C (2003). https://doi.org/10.1016/s0928-4931(02)00266-7

P.G. Bruce, B. Scrosati, J. Tarascon, Lithium batteries nanomaterials for rechargeable lithium batteries. Angew. Chem. Int. Ed. (2008). https://doi.org/10.1002/anie.200702505

X. Chen, S.S. Mao, Titanium dioxide nanomaterials: synthesis, properties, modifications and applications. Chem. Rev. (2007). https://doi.org/10.1021/cr0500535

G. Guisbiers, S. Mejia-Rosales, S. Khanal, F. Ruiz-Zepeda, R.L. Whetten, M. José-Yacaman, Gold-copper nano-alloy, “tumbaga”, in the era of nano: phase diagram and segregation. Nano Lett. (2014). https://doi.org/10.1021/nl503584q

E. Sutter, P. Sutter, Phase diagram of nanoscale alloy particles used for vapor–liquid–solid growth of semiconductor nanowires. Nano Lett. (2008). https://doi.org/10.1021/nl0719630

M. Asadikiya, H. Sabarou, M. Chen, Y. Zhong, Phase diagram for a nano-yttria-stabilized zirconia system. RSC Adv. (2016). https://doi.org/10.1039/c5ra24330k

T. Ivas, A.N. Grundy, E. Povoden-Karadeniz, L.J. Gauckler, Phase diagram of CeO 2CoO for nano-sized powders. CALPHAD Comput. Coupling Phase Diagr. Thermochem. (2012). https://doi.org/10.1016/j.calphad.2011.10.005

H.L. Lukas, S.G. Fries, B. Sundman, Computational thermodynamics: the CALPHAD method (Cambridge University Press, Cambridge, 2007). https://doi.org/10.1017/cbo9780511804137

Z.K. Liu, First-principles calculations and CALPHAD modeling of thermodynamics. J. Phase Equilibria Diffus. (2009). https://doi.org/10.1007/s11669-009-9570-6

B. Sundman, J. Ågren, A regular solution model for phases with several components and sublattices, suitable for computer applications. J. Phys. Chem. Solids (1981). https://doi.org/10.1016/0022-3697(81)90144-x

A. van de Walle, G. Ceder, Automating first-principles phase diagram calculations. J. Phase Equilibria (2002). https://doi.org/10.1361/105497102770331596

G. Ouyang, X. Tan, C.X. Wang, G.W. Yang, Solid solubility limit in alloying nanoparticles. Nanotechnology 1, 2–3 (2006). https://doi.org/10.1088/0957-4484/17/16/042

M. Cui, H. Lu, H. Jiang, Z. Cao, X. Meng, Phase diagram of continuous binary nanoalloys: size, shape, and segregation effects. Sci. Rep. (2017). https://doi.org/10.1038/srep41990

G. Guisbiers, R. Mendoza-Cruz, L. Bazán-Díaz, J.J. Velázquez-Salazar, R. Mendoza-Perez, J.A. Robledo-Torres et al., Electrum, the gold-silver alloy, from the bulk scale to the nanoscale: synthesis, properties, and segregation rules. ACS Nano (2016). https://doi.org/10.1021/acsnano.5b05755

G. Guisbiers, S. Khanal, F. Ruiz-Zepeda, J. Roque De La Puente, M. José-Yacaman, Cu–Ni nano-alloy: mixed, core-shell or Janus nano-particle? Nanoscale 6, 14630–14635 (2014). https://doi.org/10.1039/c4nr05739b

S.H. Overbury, P.A. Bertrand, G.A. Somorjai, The surface composition of binary systems. Prediction of surface phase diagrams of solid solutions. Chem. Rev. (1975). https://doi.org/10.1021/cr60297a001

S. an Mey, Thermodynamic re-evaluation of the CuNi system. CALPHAD (1992). https://doi.org/10.1016/0364-5916(92)90022-p

A. Christensen, P. Stoltze, J.K. Norskov, Size dependence of phase separation in small bimetallic clusters. J. Phys. Condens. Matter (1995). https://doi.org/10.1088/0953-8984/7/6/008

J. Lee, J. Park, T. Tanaka, Effects of interaction parameters and melting points of pure metals on the phase diagrams of the binary alloy nanoparticle systems: a classical approach based on the regular solution model. CALPHAD Comput. Coupling Phase Diagr. Thermochem. (2009). https://doi.org/10.1016/j.calphad.2008.11.001

J. Park, J. Lee, Phase diagram reassessment of Ag–Au system including size effect. CALPHAD Comput. Coupling Phase Diagr. Thermochem. (2008). https://doi.org/10.1016/j.calphad.2007.07.004

M. Wautelet, J.P. Dauchot, M. Hecq, Phase diagrams of small particles of binary systems: a theoretical approach. Nanotechnology (2000). https://doi.org/10.1088/0957-4484/11/1/302

J. Ross, R.P. Andres, Melting temperature of small clusters. Surf. Sci. (1981). https://doi.org/10.1016/0039-6028(81)90175-8

M. Wautelet, Estimation of the variation of the melting temperature with the size of small particles, on the basis of a surface-phonon instability model. J. Phys. D Appl. Phys. (1991). https://doi.org/10.1088/0022-3727/24/3/017

P. Puri, V. Yang, Effect of particle size on melting of aluminum at nano scales. J. Phys. Chem. C (2007). https://doi.org/10.1021/jp0724774

R.J.C. Brown, R.F.C. Brown, Melting point and molecular symmetry. J. Chem. Educ. (2009). https://doi.org/10.1021/ed077p724

J. Sun, S.L. Simon, The melting behavior of aluminum nanoparticles. Thermochim. Acta (2007). https://doi.org/10.1016/j.tca.2007.07.007

M. Schmidt, R. Kusche, B. Von Issendorff, H. Haberland, Irregular variations in the melting point of size-selected atomic clusters. Nature (1998). https://doi.org/10.1038/30415

Q. Jiang, S. Zhang, M. Zhao, Size-dependent melting point of noble metals. Mater. Chem. Phys. (2003). https://doi.org/10.1016/s0254-0584(03)00201-3

M. Wautelet, A.S. Shirinyan, Thermodynamics: nano vs. macro. Pure Appl. Chem. (2009). https://doi.org/10.1351/pac-con-08-07-04

G. Guisbiers, G. Abudukelimu, Influence of nanomorphology on the melting and catalytic properties of convex polyhedral nanoparticles. J. Nanoparticle Res. (2013). https://doi.org/10.1007/s11051-013-1431-x

H.M. Lu, F.Q. Han, X.K. Meng, Size-dependent thermodynamic properties of metallic nanowires. J. Phys. Chem. B. (2008). https://doi.org/10.1021/jp802888t

K.K. Nanda, S.N. Sahu, S.N. Behera, Liquid-drop model for the size-dependent melting of low-dimensional systems. Phys. Rev. A Mol. Opt. Phys. (2002). https://doi.org/10.1103/physreva.66.013208

A.S. Shirinyan, M. Wautelet, Phase separation in nanoparticles. Nanotechnology (2004). https://doi.org/10.1088/0957-4484/15/12/004

Q. Jiang, H.X. Shi, M. Zhao, Melting thermodynamics of organic nanocrystals. J. Chem. Phys. (1999). https://doi.org/10.1063/1.479489

G. Guisbiers, L. Buchaillot, Modeling the melting enthalpy of nanomaterials. J. Phys. Chem. C (2009). https://doi.org/10.1021/jp809338t

M. Singh, S. Lara, S. Tlali, Effects of size and shape on the specific heat, melting entropy and enthalpy of nanomaterials. J. Taibah Univ. Sci. (2016). https://doi.org/10.1016/j.jtusci.2016.09.011

W. Qi, Nanoscopic thermodynamics. Acc. Chem. Res. (2016). https://doi.org/10.1021/acs.accounts.6b00205

L.H. Liang, D. Liu, Q. Jiang, Size-dependent continuous binary solution phase diagram. Nanotechnology (2003). https://doi.org/10.1088/0957-4484/14/4/306

G. Li, Q. Wang, D. Li, X. Lü, J. He, Size and composition effects on the melting of bimetallic Cu–Ni clusters studied via molecular dynamics simulation. Mater. Chem. Phys. (2009). https://doi.org/10.1016/j.matchemphys.2008.10.031

H. Liao, A. Fisher, Z.J. Xu, Surface segregation in bimetallic nanoparticles: a critical issue in electrocatalyst engineering. Small (2015). https://doi.org/10.1002/smll.201403380

B.N. Wanjala, J. Luo, B. Fang, D. Mott, C.J. Zhong, Gold-platinum nanoparticles: alloying and phase segregation. J. Mater. Chem. (2011). https://doi.org/10.1039/c0jm02682d

L. Deng, W. Hu, H. Deng, S. Xiao, Surface segregation and structural features of bimetallic Au–Pt nanoparticles. J. Phys. Chem. C (2010). https://doi.org/10.1021/jp100194p

L. Peng, E. Ringe, R.P. Van Duyne, L.D. Marks, Segregation in bimetallic nanoparticles. Phys. Chem. Chem. Phys. (2015). https://doi.org/10.1039/c5cp01492a

D.R. Gaskell, Introduction to the thermodynamics of materials (CRC Press, Hoboken, 1994). https://doi.org/10.1115/1.2901487

J. Sopousek, J. Vrestal, J. Pinkas, P. Broz, J. Bursik, A. Styskalik et al., Cu–Ni nanoalloy phase diagram—prediction and experiment. CALPHAD Comput. Coupling Phase Diagr. Thermochem. (2014). https://doi.org/10.1016/j.calphad.2013.11.004

T.T. Li, C. He, W.X. Zhang, M. Cheng, Structural and melting properties of Cu–Ni clusters: a simulation study. J. Alloys Compd. (2018). https://doi.org/10.1016/j.jallcom.2018.04.145

J. Pinkas, J. Sopoušek, P. Brož, V. Vykoukal, J. Buršík, J. Vřešťál, Synthesis, structure, stability and phase diagrams of selected bimetallic silver- and nickel-based nanoparticles. CALPHAD Comput. Coupling Phase Diagr. Thermochem. (2019). https://doi.org/10.1016/j.calphad.2018.11.013

F.L. Williams, D. Nason, Binary alloy surface compositions from bulk alloy thermodynamic data. Surf. Sci. (1974). https://doi.org/10.1016/0039-6028(74)90177-0

Acknowledgements

The authors thankfully acknowledge the financial support provided by the Institution of Engineers (India) (Project ID RDDR2017014) for carrying out research and development work in this subject. The authors would like to express deepest gratitude to late| Dr. B.N.V.Subrahmanya, Smt. B.V.Seetha, Shri M Narasimhan, Shri B.K.Ramesh, Shri B.V.Venkatasubrahmanya and all the other trustees and management, Principal and HOD (Department of Mechanical Engineering) of Jyothy Charitable trust and CIIRC for their immense support in all aspects. The authors also thank Visvesvaraya Technological University, Belgaum, and the management team and Principal of PES Institute of Technology and Siddaganga Institute of Technology for their assistance.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ram, H.R.A., Venkatesh, K., Gopalakrishna, K. et al. Merging of Solidus and Liquidus Curves in Copper–Nickel Nanophase Diagram due to Segregation. J. Inst. Eng. India Ser. D 100, 243–253 (2019). https://doi.org/10.1007/s40033-019-00192-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40033-019-00192-3