Abstract

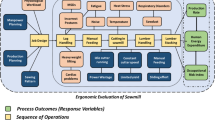

Field data based model is proposed to reduce the overhauling time and human energy consumed in liner piston maintenance activity so as to increase the productivity of liner piston maintenance activity. The independent variables affecting the phenomenon such as anthropometric parameters of workers (Eastman Kodak Co. Ltd in Section VIA Appendix-A: Anthropometric Data. Ergonomic Design for People at Work, Van Nostrans Reinhold, New York, 1), workers parameters, specification of liner piston data, specification of tools used in liner piston maintenance activity, specification of solvents, axial clearance of big end bearing and bolt elongation, workstation data (Eastman Kodak Co. Ltd in Work Place Ergonomic Design for People at Work, Van Nostrans Reinhold, New York, 2) and extraneous variables, namely, temperature, humidity at workplace, illumination at workplace and noise at workplace (Eastman Kodak Co. Ltd in Chapter V Environment Ergonomic Design for People at Work, Van Nostrans Reinhold, New York, 3) are taken into account. The model is formulated for dependent variables of liner piston maintenance activity to minimize the overhauling time and human energy consumption so as to improve the productivity of liner piston maintenance activity. The developed model can predict the performance of liner piston maintenance activity which involves man and machine system (Schenck in Theories of Engineering Experimentation, Mc-Graw Hill, New York 4). The model is then optimized by optimization technique and the sensitivity analysis of the model has also been estimated.

Similar content being viewed by others

References

Eastman Kodak Co. Ltd, Section VIA Appendix-A: Anthropometric Data. Ergonomic Design for People at Work (Van Nustrand Reinhold, New York, 1983)

Eastman Kodak Co. Ltd, Work Place Ergonomic Design for People at Work (Van Nostrans Reinhold, New York, 1983)

Eastman Kodak Co. Ltd, Chapter V Environment Ergonomic Design for People at Work (Van Nustrand Reinhold, New York, 1983)

H. Schenck Jr., Theories of Engineering Experimentation (Mc-Graw Hill, New York, 1961)

Eastman Kodak Co. ltd, Sitting Standing Seat Stand Work Place, Ergonomic Design for People at Work (Van Nostrand Reinhold, New York, 1983)

P. Belkhode, K. Borkar, J. P. Modak, Maintenance activity for locomotive crankshaft by using FDBM approach for saving the resources. Int. J. Eng. Tech. Res. ER Publ. 2(9), 112–115 (2014)

K.F.H. Muwell, Nature of Ergonomics, Ergonomics (Man in His Working Environment) (Chapman and Hall, London, 1956)

P. Belkhode, Investigation of steering parameter using artificial neural network simulation. International Journal of Computer Applications Proceedings on National Conference MEDHA 2012, pp. 20–22, (2012)

S.V. Kartalopous, Understanding Neural Networks and Fuzzy Logic (Prentice-Hall of India Pvt. Ltd., New Delhi, 2004)

S.S. Rao, Optimization Theory and Application (Wiley, Hoboken, 1994)

S. Kunar, G. Ghosh, K. Mandal, D. Bose, S. P. Sau, Measurement and evaluation of reliability, availability and maintainability of a diesel locomotive engine. IOSR J. Mech. Civ. Eng. (IOSR-JMCE), 8(1), 31–46 (2013), e-ISSN: 2278-1684, p-ISSN: 2320-334X

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Belkhode, P.N. Mathematical Modelling of Liner Piston Maintenance Activity using Field Data to Minimize Overhauling Time and Human Energy Consumption. J. Inst. Eng. India Ser. C 99, 701–709 (2018). https://doi.org/10.1007/s40032-017-0377-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40032-017-0377-7