Abstract

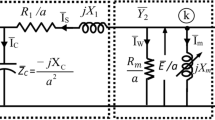

Power inductors are used for compensating VAR generated by long EHV transmission lines and in electronic circuits. For the EHV-lines, the rating of the inductor is decided upon by techno-economic considerations on the basis of the line-susceptance. It is a high voltage high current device, absorbing little active power and large reactive power. The cost is quite high- hence the design should be made cost-optimally. The 3-phase power inductor is similar in construction to a 3-phase core-type transformer with the exception that it has only one winding per phase and each limb is provided with an air-gap, the length of which is decided upon by the inductance required. In this paper, a design methodology based on sequential gradient search technique and the corresponding algorithm leading to cost-optimal design of a 3-phase EHV power inductor has been presented. The case-study has been made on a 220 kV long line of NHPC running from Chukha HPS to Birpara of Coochbihar.

Similar content being viewed by others

References

M.D. Singh, K.B. Kanchandani, Power Electronics, (Tata McGraw-Hill Education), ISBN: 978-0-07-058389-4

J.J. Grainger, W.D. Stevenson Jr., Power System Analysis, (Tata McGraw-Hill Education, 2003), ISBN: 0-07-058515-6

A. Maity, K. Bhattacharya, A.N. Sanyal, Cost optimal design of a 3-phase 400 Kv power inductor for compensating an EHV line. Int. J. Emerg. Technol. Adv. Eng. 2(9) (2012), ISSN: 2250–2459 (online)

H. Partab, Art and Science of Utilization of Electrical Energy (Dhanpat Rai and Co., New Delhi, 2010)

A.K. Shawney, A Course in Electrical Machine Design (Dhanpat Rai & Sons, New Delhi, 2003)

R. Basak, A. Das, A. Sensarma, A.N. Sanyal, Discrete design optimization of small open type dry transformers. Bulletin Teknik Elektrodan Informatika 1(1), 37–42 (2012). ISSN: 2089-319

A. Chakraborty, S. Halder, Power System Analysis, Operation and Control, (PHI Learning Pvt. Ltd.), ISBN: 978-81-203-4015-2

M.V. Deshpande, Electrical Power System Design, (Tata McGraw-Hill Education), ISBN-13: 978-0-07-451575-4; ISBN-10: 0-07-451575-6

H. Nagaoka, The inductance coefficients of solenoids. J. Coll Sci. 27(3), 31 (1909)

M.G. Say, Performance and Design of AC Machines, (CBS Publishers and Distributors, 2002), ISBN: 10:8123910274

M. Ramamoorty, Computer-Aided Design of Electrical Equipment, (Affiliated East-West Press, 1987), ISBN: 81-85095-57-4

K. Deb, Optimization for Engineering Design, (PHI Learning Pvt. Ltd., 2010), ISBN: 978-81-203-0943-2

S.S. Rao, Engineering Optimization- Theory and Practice, (New Age International), ISBN: 978-81-224-2723-3

NHPC Ltd. BSE Design Engineering, Construction, Execution, Testing and Commissioning of Transmission Lines. (2013)

A. Shanmugasundaram, G. Gangadharan, R. Palani, Electrical Machine Design Data Book, (Wiley Eastern Ltd.), ISBN: 0 85226 813 0

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix 1

[Subroutine for the Design of Power Inductor]

Input \( S \leftarrow MVAR \) to be compensated \( S^{'} \leftarrow 1000 \times S/2 \) | // rating of the inductor in KVA |

Input \( f,V,K,R_{w} ,K_{s} \) | // frequency, line voltage, emf constant, |

// window height/width ratio, stacking factor | |

Input \( K_{w} ,K_{c} ,B_{m} ,\delta \) | // window space factor, constant depending on no of steps, |

// maximum flux density, current density (A/mm2) | |

\( E_{t} \leftarrow K\sqrt {S^{'} } \) | // emf per turn, V |

\( V_{p} \leftarrow V/\sqrt 3;\,\,N \leftarrow V_{p} /E_{t} \) | // phase voltage, no of turns |

\( \phi_{m} \leftarrow E_{t} /(4.44f) \); \( I = s \times 10^{6} /(3V_{p} ) \) | // maximum value of flux, current |

\( A_{i} \leftarrow \phi_{m} /B_{m};\,\,\,A_{gi} \leftarrow A_{i} /K_{s} \,\,;\,\,a_{c} \leftarrow I/\delta \) | // net/gross area of iron, conductor area |

Input \( N_{st} ,K_{1} \ldots \) | // number of core steps, corresponding length coefficients |

\( d \leftarrow \sqrt {A_{gi} /K_{c} };\,\,a \leftarrow K_{1} d \) | // diameter of the fictitious circle round the core; |

// length of the largest core step | |

\( A_{w} \leftarrow S^{{\prime }} /3.33fB_{m} A_{i} K_{w} \delta \times 10^{3} \) | // window area |

\( W_{w} \leftarrow \sqrt {A_{w} /R_{w} };\,\,H_{w} \leftarrow R_{w} W_{w} \) | // window width, height |

\( D_{c} \leftarrow W_{w} + d;\,\,W = 2D_{c} + a \) | // distance between core centres, total length of the core |

\( A_{gy} \leftarrow A_{gi} ;\,\,\,W_{y} \leftarrow a\,\,\,\,\,\,\, \) | // gross area, width of yoke |

\( \,H_{y} \leftarrow A_{gy} /W_{y} \) \( H \leftarrow H_{w} + 2H_{y} \) | // height of yoke, total height of core |

Input \( c_{w} ,c_{l} ,c_{h} \) | // tank clearances |

\( t_{w} \leftarrow D_{c} + 2c_{w} ;\,\,t_{l} \leftarrow W + 2c_{l} \,\,;\,\,t_{h} = H + c_{h} \) | // tank dimensions |

\( t_{a} \leftarrow 2(t_{l} + t_{w} )t_{h} + t_{l} t_{w} \) | // tank area for radiation |

Input \( p_{i} ,\rho ,\rho_{i} ,\rho_{c} \) | // specific iron loss, resistivity of conductor, density of iron, conductor |

\( V_{i} = (2W + 3H_{w} )A_{i} ;\,\,W_{i} = V_{i} \rho_{i} \,\,;\,\,\,P_{i} = W_{i} p_{i} \) | // volume, weight of iron, total iron loss |

\( L_{mt} = \pi (D_{c} - c_{wd} )\,\,;\,\,R \leftarrow \rho L_{mt} N/a_{c} \,\,;\,\,P_{c} = 3I^{2} R \) | // length of mean turn, resistance, total ohmic loss |

\( P_{ls} = P_{c} + P_{i} ;\,\,V_{c} = NL_{mt} a_{c} \times 10^{ - 6} \) | // total loss, volume of conductor |

Input \( V_{a} ,\lambda_{r} ,\lambda_{c} ,d_{t} \) | // velocity of air blast, dissipation by radiation, convection, |

// depth of tank wall | |

\( \lambda_{c}^{'} \leftarrow \lambda_{c} (1 + 1.3\sqrt {V_{a} } );\,\,V_{oil} = t_{h} t_{l} t_{w} K \) | // dissipation coefficient with air-blast, volume of oil |

// increased convection due to air-blast at 40 °C | |

\( x = t_{a} \lambda_{r} \times 40;\,\,t_{t} = (p_{ls} - x)/(\lambda_{c}^{'} \times 40) \) | // dissipation through radiation, total area of cooling tubes in the radiator |

\( Input\,s_{i} ,s_{c} ,s_{t} ,s_{o} \,\, - specific\,\,costs \) | |

\( C_{c} = V_{c} \rho_{c} s_{c} \); \( C_{i} = V_{i} \rho_{i} s_{i} \) | // cost of copper and iron |

\( C_{\tan k} \leftarrow (t_{a} + t_{t} )d_{t} \rho_{i} s_{t} \) | // cost of tank |

\( C_{oil} = V_{oil} s_{o} /1000 \) | // cost of transformer oil |

\( C_{t} = (C_{c} + C_{i} + C_{\tan k} + C_{oil} )(1 + OH) \) | // total cost along with overheads |

Appendix 2

[Cost Optimal design of a 3-Phase Power Inductor by Exhaustive Search]

Minimum cost 2,714,322/- is obtained for K = 0.43; Rw = 3.72

The design details of the cost-optimal power inductor:

-

KVA-rating of the inductor = 15,000; rated line voltage = 220,000 V

-

Nominal frequency = 50 Hz; connection: Y

-

Conductor material: COPPER; current density = 3.2 A/sq. mm

-

Core material CRGOS: flux-density = 1.7 Tesla

-

Number of turns of the coil = 2933

-

Current in coil = phase current = 39.368 A

-

Current density = 3.2 A/sq. mm; cross section of the conductor = 12.302 sq. mm

-

Net area of core iron = 0.1147357 sq. m; stacking factor = 0.972

-

Gross area of core iron = 0.1180409 sq. m; 3-stepped core has been used.

-

Diameter of the core circle = 0.4229 m

-

Length of the core sides in m: = 0.383/0.299/0.179

-

Area of the window = 0.3608 sq. m

-

Window height/width ratio = 3.72; window height/width in m: 1.1709/0.3081

-

Distance between core centres = 0.6909 m

-

Width/height of yoke in m: 0.3827/0.3084

-

Total length of core = 1.8448 m; total height of core = 1.7878 m

-

Length of air-gap = 0.313 mm

-

Volume of iron = 0.8264 cu. m; weight of iron = 6321.74 kg

-

Iron loss/kg at this flux-density = 2.0966 W; iron loss = 13,254 W; % iron loss = 8.836E−02

-

Mean length of turn = 1.7158 m; resistance of the coil = 9.0001 Ω

-

Copper loss = 41,839.4 W; % copper loss = 0.27893; total % loss = 0.36729

-

The tank length × width × height: 2.273 × 0.851 × 2.188

-

Artificial cooling by air-blast on radiators is being used.

-

The velocity of blast = 5 m/s; the blast constant (with some non-uniformity in blast) = 1.1

-

The dissipation constant in = 35.234 W/sq. m/°C

-

The number of elliptical tubes (75 × 25 mm) in the radiator = 110

-

The cost of sheet metal/kg = Rs. 50/-

-

The weight/cost of tank: 913.4537 kg; Rs. 45,673/-

-

The cost of oil/litre = Rs. 40/-

-

The volume/cost of oil: 4.231074 cu. m; Rs. 169,243/-

-

Volume of iron = 0.82637 cu. m; weight of iron = 6321.7 kg

-

Cost of iron/kg = Rs. 150/-; cost of iron = Rs. 948,261/-

-

Volume of copper = 0.1857 cu. m; weight of copper = 1652.9 kg

-

Cost of copper/kg = Rs. 450/-; cost of copper = Rs. 743,816/-

-

Direct cost allowing 15% labour charge = Rs. 2,193,042/-

-

Selling cost allowing 25% overhead = Rs. 2,741,302/-

Rights and permissions

About this article

Cite this article

Basak, R., Das, A. & Sanyal, A. Cost Optimal Design of a Power Inductor by Sequential Gradient Search. J. Inst. Eng. India Ser. B 99, 413–418 (2018). https://doi.org/10.1007/s40031-018-0329-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40031-018-0329-5