Abstract

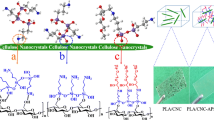

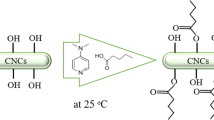

The classical approach to prepare nanocomposites is often applied to chemical or physical modification of nanofillers to improve interfacial interaction between nanofillers and matrices. However, those methods might disturb the original reinforcement of nanoparticles due to the inhibition and even the absence of association among fillers. Here, we inspected a molecular design strategy using rod-like cellulose nanocrystals (CNCs) as fillers to study whether regulating the surface structure of CNC could allow a better reinforcement effect. Toward that, we prepared four modified CNCs by esterification with mono or binary anhydrides of different lengths of carbon chains. The long hydrocarbon chains were supposed to further improve the interfacial compatibility between CNC and poly(lactic acid) (PLA), and the terminal carboxyl groups should retain the association between nanoparticles. Results from transmittance of visible light for the nanocomposite films revealed homogeneous dispersion and good compatibility between modified nanocrystals and PLA matrix, especially for the long carbon-chain grafting CNCs. With an addition of 4 wt% dodecenyl succinic anhydride-modified CNC, the nanocomposite showed an increase in the tensile strength by ca. 170%. This was ascribed to the improved entanglement of grafting long chains and the potential interaction of terminal carboxyl groups on the CNC surface with the segments of PLA matrix, which enhanced association and compatibility between nanoparticles and matrix. This strategy prepared a biomass alloy of green materials reinforced by natural polymers and promoted the sustainable development of materials with high mechanical properties.

Similar content being viewed by others

References

Azizi Samir MAS, Alloin F, Dufresne A (2005) Review of recent research into cellulosic whiskers, their properties and their application in nanocomposite field. Biomacromol 6:612–626

Lin N, Huang J, Dufresne A (2012) Preparation, properties and applications of polysaccharide nanocrystals in advanced functional nanomaterials: a review. Nanoscale 4:3274–3294

Lin N, Huang J, Chang PR, Feng L, Yu J (2011) Effect of polysaccharide nanocrystals on structure, properties, and drug release kinetics of alginate-based microspheres. Colloid Surf B Biointerfaces 85:270–279

Darpentigny C, Molina-Boisseau S, Nonglaton G (2020) Ice-templated freeze-dried cryogels from tunicate cellulose nanocrystals with high specific surface area and anisotropic morphological and mechanical properties. Cellulose 27:233–247

Wang S, Zhang X, Wu X (2016) Tailoring percolating conductive networks of natural rubber composites for flexible strain sensors via a cellulose nanocrystal templated assembly. Soft Matter 12:845–852

Li D, Wang Y, Long F, Gan L, Huang J (2020) Solvation-controlled elastification and shape-recovery of cellulose nanocrystal-based aerogels. ACS Appl Mater Interfaces 12:1549–1557

Zhang Y, Liu G, Yao X, Gao S, Xie J, Xu H, Lin N (2018) Electrochemical chiral sensor based on cellulose nanocrystals and multiwall carbon nanotubes for discrimination of tryptophan enantiomers. Cellulose 25:3861–3871

Sun Q, Qian B, Uto K, Chen J, Liu X, Minari T (2018) Functional biomaterials towards flexible electronics and sensors. Biosens Bioelectron 119:237–251

Gopinath V, Saravanan S, Al-Maleki A, Ramesh M, Vadivelu J (2018) A review of natural polysaccharides for drug delivery applications: special focus on cellulose, starch and glycogen. Biomed Pharmacother 107:96–108

Tang L, Lin F, Li T, Cai Z, Hong B, Huang B (2018) Design and synthesis of functionalized cellulose nanocrystals-based drug conjugates for colon-targeted drug delivery. Cellulose 25:4525–4536

Habibi Y, Lucia LA, Rojas OJ (2010) Cellulose nanocrystals: chemistry, self-assembly, and applications. Chem Rev 110:3479–3500

Favier V, Canova G, Cavaillé J, Chanzy H, Dufresne A, Gauthier C (1995) Nanocomposite materials from latex and cellulose whiskers. Polym Adv Technol 6:351–355

Liu Y, Yu Y, Wang Q, Xu J, Fan X, Wang P, Yuan J (2019) Biological–chemical modification of cellulose nanocrystal to prepare highly compatible chitosan-based nanocomposites. Cellulose 26:5267–5279

Jonoobi M, Ashori A, Siracusa V (2019) Characterization and properties of polyethersulfone/modified cellulose nanocrystals nanocomposite membranes. Polym Test 76:333–339

Mabrouk AB, Dufresne A, Boufi S (2020) Cellulose nanocrystal as ecofriendly stabilizer for emulsion polymerization and its application for waterborne adhesive. Carbohydr Polym 229:115–504

Parambath KB, Claudino M, Johansson M, Berglund LA, Zhou Q (2015) Biocomposites from natural rubber: synergistic effects of functionalized cellulose nanocrystals as both reinforcing and cross-linking agents via free-radical thiol-ene chemistry. ACS Appl Mater Interfaces 7:16303–16310

Fortunati E, Armentano I, Zhou Q, Iannoni A, Saino E, Visai L, Berglund LA, Kenny JM (2012) Multifunctional bionanocomposite films of poly(lactic acid), cellulose nanocrystals and silver nanoparticles. Carbohydr Polym 87:1596–1605

Bundjaja V, Sari TM, Soetaredjo FE, Yuliana M, Angkawijaya AE, Ismadji S, Cheng KC, Santoso SP (2020) Aqueous sorption of tetracycline using rarasaponin-modified nanocrystalline cellulose. J Mol Liq 301:112433

Song K, Xu H, Xie K, Yang Y (2017) Keratin-based biocomposites reinforced and cross-linked with dual-functional cellulose nanocrystals. ACS Sustain Chem Eng 5:5669–5678

Yu HY, Qin ZY, Yan CF, Yao JM (2014) Green nanocomposites based on functionalized cellulose nanocrystals: a study on the relationship between interfacial interaction and property enhancement. ACS Sustain Chem Eng 2:875–886

Ahmadi M, Behzad T, Bagheri R (2017) Reinforcement effect of poly(methyl methacrylate)-g-cellulose nanofibers on LDPE/thermoplastic starch composites: preparation and characterization. Iran Polym J 26:733–742

Xu C, Chen J, Wu D, Chen Y, Lv Q, Wang M (2016) Polylactide/acetylated nanocrystalline cellulose composites prepared by a continuous route: a phase interface-property relation study. Carbohydr Polym 146:58–66

Hu F, Lin N, Chang PR, Huang J (2015) Reinforcement and nucleation of acetylated cellulose nanocrystals in foamed polyester composites. Carbohydr Polym 129:208–215

Tao H, Dufresne A, Lin N (2019) Double-network formation and mechanical enhancement of reducing end-modified cellulose nanocrystals to the thermoplastic elastomer based on click reaction and bulk cross-linking. Macromolecules 52:5894–5906

Cao L, Fan J, Huang J, Chen Y (2019) A robust and stretchable cross-linked rubber network with recyclable and self-healable capabilities based on dynamic covalent bonds. J Mater Chem A 7:4922–4933

Wang Y, Xie R, Li D, Shen Y, Xie W, Wang H, Gan L, Huang J (2020) A crosslinking/percolating-integrated strategy to enhance crystallizable rubber using rod-like reactive bio-based nanocrystals. ACS Appl Bio Mater 3:441–449

Wohlhauser S, Kuhnt T, Meesorn W, Montero de Espinosa L, Zoppe JO, Weder C (2020) One-component nanocomposites based on polymer-grafted cellulose nanocrystals. Macromolecules 53:821–834

Lin G, Liao J, Ning L, Hu C, Wang H, Jin H (2017) Focus on gradientwise control of the surface acetylation of cellulose nanocrystals to optimize mechanical reinforcement for hydrophobic polyester-based nanocomposites. ACS Omega 2:4725–4736

Li L, Tao H, Wu B, Zhu G, Li K, Lin N (2018) Triazole end-grafting on cellulose nanocrystals for water-redispersion improvement and reactive enhancement to nanocomposites. ACS Sustain Chem Eng 6:14888–14900

Miao C, Hamad WY (2019) Critical insights into the reinforcement potential of cellulose nanocrystals in polymer nanocomposites. Curr Opin Solid State Mater Sci 23:100761

Lin N, Dufresne A (2013) Physical and/or chemical compatibilization of extruded cellulose nanocrystal reinforced polystyrene nanocomposites. Macromolecules 46:5570–5583

Henna R, Eero K, Jani S, Erkki K, Olli I (2013) Transition to reinforced state by percolating domains of intercalated brush-modified cellulose nanocrystals and poly(butadiene) in cross-linked composites based on thiol-ene click chemistry. Biomacromol 14:1547–1554

Tian M, Zhen X, Wang Z, Zou H, Zhang L, Ning N (2017) Bioderived rubber-cellulose nanocrystal composites with tunable water-responsive adaptive mechanical behavior. ACS Appl Mater Interfaces 9:6482–6487

Cao L, Fu X, Xu C, Yin S, Chen Y (2017) High-performance natural rubber nanocomposites with marine biomass (tunicate cellulose). Cellulose 24:2849–2860

Segal L, Creely JJ, Martin AE, Conrad CM (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text Res J 29:786–794

Holzwarth U, Gibson N (2011) The Scherrer equation versus the 'Debye–Scherrer equation'. Nat Nanotechnol 6:534

Owens DK, Wendt RC (1969) Estimation of the surface free energy of polymers. J Appl Polym Sci 13:1741–1747

Lin N, Huang J, Chang PR, Feng J, Yu J (2012) Surface acetylation of cellulose nanocrystal and its reinforcing function in poly(lactic acid). Carbohydr Polym 83:1834–1842

Ly EHB, Bras J, Sadocco P, Belgacem MN, Dufresne A, Thielemans W (2010) Surface functionalization of cellulose by grafting oligoether chains. Mater Chem Phys 120:438–445

Zhang Q, Wei S, Huang J, Feng J, Chang PR (2014) Effect of surface acetylated-chitin nanocrystals on structure and mechanical properties of poly(lactic acid). J Appl Polym Sci 131:265–280

Peresin MS, Habibi Y, Zoppe JO, Pawlak JJ, Rojas OJ (2010) Nanofiber composites of polyvinyl alcohol and cellulose nanocrystals: manufacture and characterization. Biomacromol 11:674–681

Frisoni G, Baiardo M, Scandola M, Lednicka D, Cnockaert MC, Mergaert J, Swings J (2001) Natural cellulose fibers: heterogeneous acetylation kinetics and biodegradation behavior. Biomacromol 2:476–482

Espert A, Vilaplana F, Karlsson S (2004) Comparison of water absorption in natural cellulosic fibres from wood and one-year crops in polypropylene composites and its influence on their mechanical properties. Compos Part A Appl Sci Manuf 35:1267–1276

Shopsowitz KE, Qi H, Hamad WY, Maclachlan MJ (2010) Free-standing mesoporous silica films with tunable chiral nematic structures. Nature 468:422–425

Yu HY, Chen R, Chen GY, Liu L, Yang XG, Yao JM (2015) Silylation of cellulose nanocrystals and their reinforcement of commercial silicone rubber. J Nanoparticle Res 17:1–13

Kowalczyk M, Piorkowska E, Kulpinski P, Pracella M (2011) Mechanical and thermal properties of PLA composites with cellulose nanofibers and standard size fibers. Compos Part A Appl Sci Manuf 42:1509–1514

Acknowledgements

This research is financially supported by the National Natural Science Foundation of China (51973175 and 51373131), the Project for Chongqing University Innovation Research Group of Chongqing Education Committee (CXQT19008), and the Chongqing Talent Plan for Innovation and Entrepreneurship Demonstration Team (CQYC201903243).

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

Below is the link to the electronic supplementary material.

13726_2020_832_MOESM1_ESM.docx

Supplementary file1. Supporting Information. The ratio of reaction materials; DSC and DMA data of Tg, Tm, ΔHm, and crystallinity for PLA and its nanocomposites; the equation about how to calculate the mass mole of hydroxyl groups on CNCs; 13C CP-MAS NMR of the CNC and modified CNCs; XRD patterns of CNC and modified CNCs; DSC spectra of PLA and its nanocomposites (DOCX 7618 kb)

Rights and permissions

About this article

Cite this article

Wang, Y., Liao, J., Lu, J. et al. Regulating surface molecular structure of cellulose nanocrystals to optimize mechanical reinforcement effect on hydrophobic bio-based polyesters. Iran Polym J 29, 693–705 (2020). https://doi.org/10.1007/s13726-020-00832-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-020-00832-6