Abstract

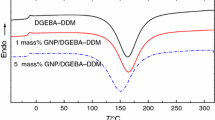

A new UV-curable hyperbranched silicone epoxy acrylate resin was synthesized, and two kinds of carbon-based components, graphite and graphene, were applied as conductive materials. An ultraviolet-curing coating was successfully synthesized with using epoxy acrylate (EA) as oligomer, butyl acrylate (BA), and hyperbranched polysiloxane (HPSi) as monomers, benzoin dimethyl ether (DMPA), and benzophenone (BP) as photo-initiators, triethanolamine (TEA) as photo-activator, and other auxiliaries. In this work, the UV-curing efficiency and cured performance, together with the effect of different conductive fillers and the amount of conductive filler on the integrated performance of the composites, are investigated. The results show that as the HPSi content increases, the curing time is shortened. At the addition amount of 7.5%, it reaches the best conductivity, and at the addition amount of 10%, the corrosion resistance after curing is the best. However, the maximum tensile strength of 10.4% is obtained at 0.75 graphene. The FE-SEM micrographs of the UV-curable conductive coating show that with increasing incorporation of graphene into the substrate, the fractured surface of a rough surface changes to smooth one. Thermal properties of the films investigated using TGA curves indicate that graphene-doped conductive adhesive film (315.1 °C) possesses much higher heat resistance than that of graphite-doped conductive adhesive film.

Similar content being viewed by others

References

DuránRetamal JR, Kang CF, Lien DH, Kuo WC, Juang ZY, Tsai ML, Ho CH, Juang JY, Hsiao VKS, Chu YH, Li LJ, Wu Y, He JH (2018) A nanostructuring method to decouple electrical and thermal transport through the formation of electrically triggered conductive nanofilaments. Adv Mater 30:1705385

Yoshida K, Ning T, Masahiro Y, Abe R, Higuchi Y (2013) Conductive polymer solution, antistatic coating material, antistatic hard coat layer, optical filter, conductive coating film, antistatic tacky adhesive, antistatic tacky adhesive layer, protective material, and method for producing the same. US Patent 8414801

Enríquez E, Fernández JF, De la Rubia MA (2012) Highly conductive coatings of carbon black/silica composites obtained by a sol–gel process. Carbon 50:4409–4417

Park JM, Jeon JH, Lee YH, Lee DJ, Park H, Chun HH, Do Kim H (2015) Synthesis and properties of uv-curable polyurethane acrylates containing fluorinated acrylic monomer/vinyltrimethoxysilane. Polym Bull 72:1921–1936

Noreen A, Zia KM, Zuber M, Tabasum S, Saif MJ (2016) Recent trends in environmentally friendly water-borne polyurethane coatings: a review. Korean J Chem Eng 33:388–400

Sangermano M, Foix D, Kortaberria G, Messori M (2013) Multifunctional antistatic and scratch resistant UV-cured acrylic coatings. Prog Org Coat 76:1191–1196

Hwang HD, Kim HJ (2011) UV-curable low surface energy fluorinated polycarbonate-based polyurethane dispersion. J Colloid Interface Sci 362:274–284

Prządka D, Marcinkowska A, Andrzejewska E (2016) Poss-modified UV-curable coatings with improved scratch hardness and hydrophobicity. Prog Org Coat 100:165–172

Shi Y, Wu Y, Zhu L, Shentu B, Weng Z (2015) Preparation and properties of phase-change heat-storage UV-curable polyurethane acrylate coating. J Appl Polym Sci 132:41266

Xu J, Jiang Y, Qiu F, Dai Y, Yang D, Yu Z, Yang P (2018) Synthesis, mechanical properties and iron surface conservation behavior of UV-curable waterborne polyurethane-acrylate coating modified with inorganic carbonate. Polym Bull 75:1–22

Prządka D, Andrzejewska E, Marcinkowska A (2015) Multimethacryloxy-poss as a crosslinker for hydrogel materials. Eur Polym J 72:34–49

Kalaitzidou K, Fukushima H, Drzal LT (2010) A route for polymer nanocomposites with engineered electrical conductivity and percolation threshold. Materials 3:1089–1103

Gelves GA, Lin B, Sundararaj U, Haber JA (2008) Electrical and rheological percolation of polymer nanocomposites prepared with functionalized copper nanowires. Nanotechnology 19:215712

Cao XG, Zhang HY (2012) Preparation of silver-coated copper powder and its oxidation resistance research. Powder Technol 226:53–56

Wang T, Chen G, Wu C, Wu D (2007) Study on the graphite nanosheets/resin shielding coatings. Prog Org Coat 59:101–105

Yang S, Lozano K, Lomeli A, Foltz HD, Jones R (2005) Electromagnetic interference shielding effectiveness of carbon nanofiber/LCP composites. Composites Part A 36:691–697

Martin-Gallego M, Lopez-Manchado MA, Calza P, Roppolo I, Sangermano M (2015) Gold-functionalized graphene as conductive filler in UV-curable epoxy resin. J Mater Sci 50:605–610

Yasmin A, Daniel IM (2004) Mechanical and thermal properties of graphite platelet/epoxy composites. Polymer 45:8211–8219

Yasmin A, Luo JJ, Daniel IM (2006) Processing of expanded graphite reinforced polymer nanocomposites. Compos Sci Technol 66:1182–1189

Azim SS, Satheesh A, Ramu KK, Ramu S, Venkatachari G (2006) Studies on graphite based conductive paint coatings. Prog Org Coat 55:1–4

Meyer JC, Geim AK, Katsnelson MI, Novoselov KS, Booth TJ, Roth ST (2007) The structure of suspended grapheme sheets. Nature 446:60–63

Yu X, Zhang W, Zhang P, Su Z (2016) Fabrication technologies and sensing applications of graphene-based composite films: advances and challenges. Biosens Bioelectron 89:72–84

Lee C, Wei X, Kysar JW, Hone J (2008) Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science 321:385–388

Choi W, Lahiri I, Seelaboyina R, Kang YS (2010) Synthesis of graphene and its applications: a review. Crit Rev Solid State Mater Sci 35:52–71

Owens FJ (2014) Pentacene and poly-pentacene as graphenenanoribbons. Solid State Commun 185:58–61

Kucinskis G, Bajars G, Kleperis J (2013) Graphene in lithium ion battery cathode materials: a review. J Power Sour 240:66–79

Hessein A, El-Moneim AA (2015) Developing cost effective grapheneconductive coating and its application as counter electrode for CdSquantum dot sensitized solar cell. In: Proceedings of the World Congress on New Technologies, Barcelona, Spain, July, Paper No. 307

Wang W, Jayatissa AH (2015) Comparison study of graphene based conductive nanocomposites using poly(methyl methacrylate) and polypyrrole as matrix materials. J Mater Sci Mater Electron 26:7780–7783

Panatarani C, Muthahhari N, Rianto A, Joni IM (2016) Purification and preparation of graphite oxide from natural graphite. Am Ins Phys Conf Ser 1719:183–191

Liu P, Gu A, Liang G, Guan Q, Yuan L (2012) Preparation and properties of novel high performance UV-curable epoxy acrylate/hyperbranchedpolysiloxane coatings. Prog Org Coat 74:142–150

Shen J, Hu Y, Li C, Qin C, Shi M, Ye M (2009) Layer-by-layer self-assembly of graphenenanoplatelets. Langmuir ACS J Surfaces Colloids 25:6122–6128

Mansour SH, Mostafa N, Abd-El-Messieh L (2007) Electrical and positron annihilation study on epoxy and epoxy acrylate composites. Eur Polym J 43:4770–4782

Kanie T, Fujii K, Arikawa H, Inoue K (2000) Flexural properties and impact strength of denture base polymer reinforced with woven glass fibers. Dental Mater 16:150–158

Liu W, Koh KL, Lu J, Yang L, Phua S, Kong J, Chen Z, Lu X (2012) Simultaneous catalyzing and reinforcing effects of imidazole-functionalized graphene in anhydride-cured epoxies. J Mater Chem 22:18395–18402

Zhan Y, Lavorgna M, Buonocore G, Xia H (2012) Enhancing electrical conductivity of rubber composites by constructing interconnected network of self-assembled graphene with latex mixing. J Mater Chem 22:10464–10468

Lee BS (2018) Effect of phonon scattering by substitutional and structural defects on thermal conductivity of 2D graphene. J Phys Condens Matter 30:295302

Sarwar MI, Zulfiqar S, Ahmad Z (2009) Properties of polyamide-zirconia nanocomposites prepared from sol-gel technique. Polym Compos 30:95–100

Liao YU, Luo SW RR (2010) Research of common photoinitiators applied in UV-curable coatings. Shanghai Coat 8:007

Acknowledgements

This work was supported by the National Natural Science Foundation of China (41372367), the Science and Technology Support Program of Hubei Province (2015BAA096, 2015BAA108) and the Public Service Project of the Chinese Ministry of Land and Resources (201311024).

Author information

Authors and Affiliations

Corresponding author

Additional information

Feng Bao and Rui Ma are contributed equally to this work.

Rights and permissions

About this article

Cite this article

Yan, F., Bao, F., Yan, S. et al. Hyperbranched polysiloxane-modified UV-curable graphene conductive coatings: preparation and characterization. Iran Polym J 27, 939–949 (2018). https://doi.org/10.1007/s13726-018-0666-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-018-0666-x